Table of Contents

In our previous blog post, we explored why China is a the best choice for global CNC machining services.

Today, to meet the growing market demand for ultra-high precision, complex geometries, and integrated CNC machined components, leading Chinese CNC factories are increasingly investing in 5-axis machining centers to further enhance their machining and manufacturing capabilities.

This blog is your ultimate guide for an in-depth analysis of 5-axis machining.

We will start with the basics, systematically explain the core types of 5-axis machines, then the advantages of 5-axis technology, its key applications in different industries, real-world case studies of machined parts along with inspection methods for 5-axis machined parts.

Finally, based on our expertise in online equipment sourcing, we will provide a practical list of trusted 5-axis machining equipment suppliers.

Key Takeaways:

- 5-axis CNC machining is a manufacturing process where a cutting tool moves along five axes simultaneously (X, Y, Z, and two rotational axes, A and B).

- 5-axis machines are classified by three main standards: by construction type into gantry (for large parts), vertical (for precision parts), and horizontal (for mass production); by mechanical structure into table-rotating, spindle-head-rotating, and hybrid types; and by motion mode into 3+2 positional machining and 5-axis simultaneous machining.

- A complete comparision: 3+2 positional machining VS 5-axis simultaneous machining.

- Top 5 brands ranked in the world: DMG Mori (Germany/Japan) GROB (Germany) HERMLE (Germany) MAZAK (Japan) Makino (Japan).

1. What is 5-Axis CNC Machining?

5-Axis CNC machining is a manufacturing process that uses computer numerical control (CNC) systems to operate 5-axis CNC machines capable of moving a cutting tool or a workpiece along five distinct axes simultaneously.

Unlike traditional 3-axis machining, where the tool moves linearly along the X, Y, and Z axes (left-right, forward-backward, and up-down), 5-axis machine introduces two additional rotational axes, typically referred to as A and B.

This enables the cutting tool to approach the workpiece from virtually any direction, significantly expanding machining possibilities.

Let’s say, a 3-axis machine is like a high-end engraver—it moves up and down, left and right, and forward and backward.

A 5-axis machine, on the other hand, operates like a highly flexible robotic arm: not only can it move linearly, but its “wrist” can also rotate 360°, allowing it to access the workpiece from any angle.

As the core and foundation of 5-axis machining technology, the 5-axis CNC machine is more than just a “tool” for achieving multi-axis machining—it is the critical to transform complex designs from blueprints into reality.

Now, we introduce its main classifications.

2. 5-Axis CNC Machine Classification

We will classify 5-axis machine according to three primary standards: machine construction type, mechanical structure, and rotational axis movement.

2.1. Gantry, Vertical, and Horizontal 5-Axis CNC Machines(Based on Machine Construction Type)

Base on machine construction type, 5-axis CNC machines can be classified into Gantry 5-Axis Machine, Vertical 5-Axis Machine and Horizontal 5-Axis Machine.

2.1.1. Gantry 5-Axis Machine

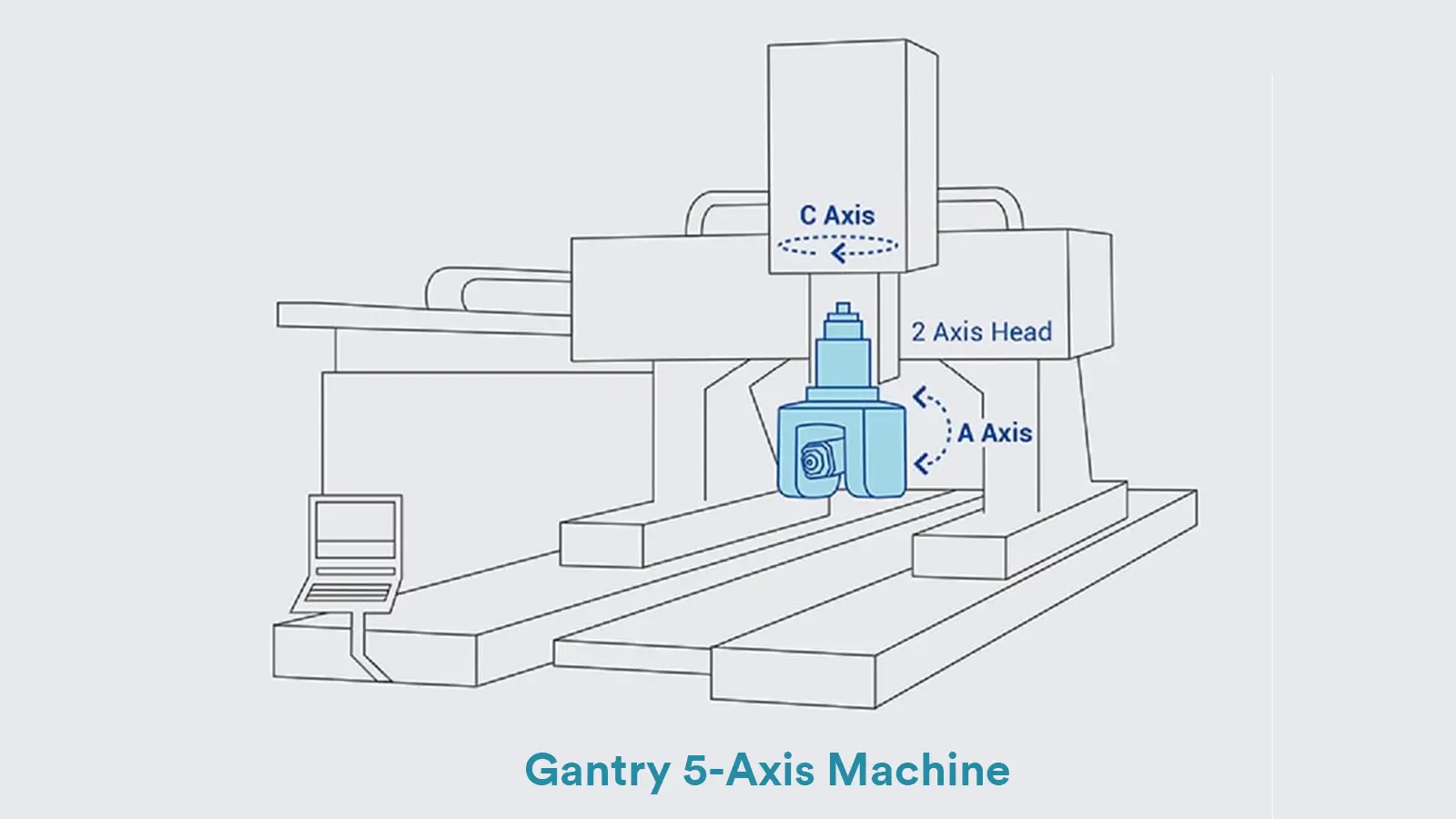

The gantry-type 5-axis CNC machine has a highly stable structure, typically featuring a wide bed and side supports, making it suitable for large-size, high-rigidity, and high-precision machining.

It is ideal for high-precision machining of large workpieces, widely used in heavy machinery, aerospace, large mold and other industries.

2.1.2. Vertical 5-Axis Machine

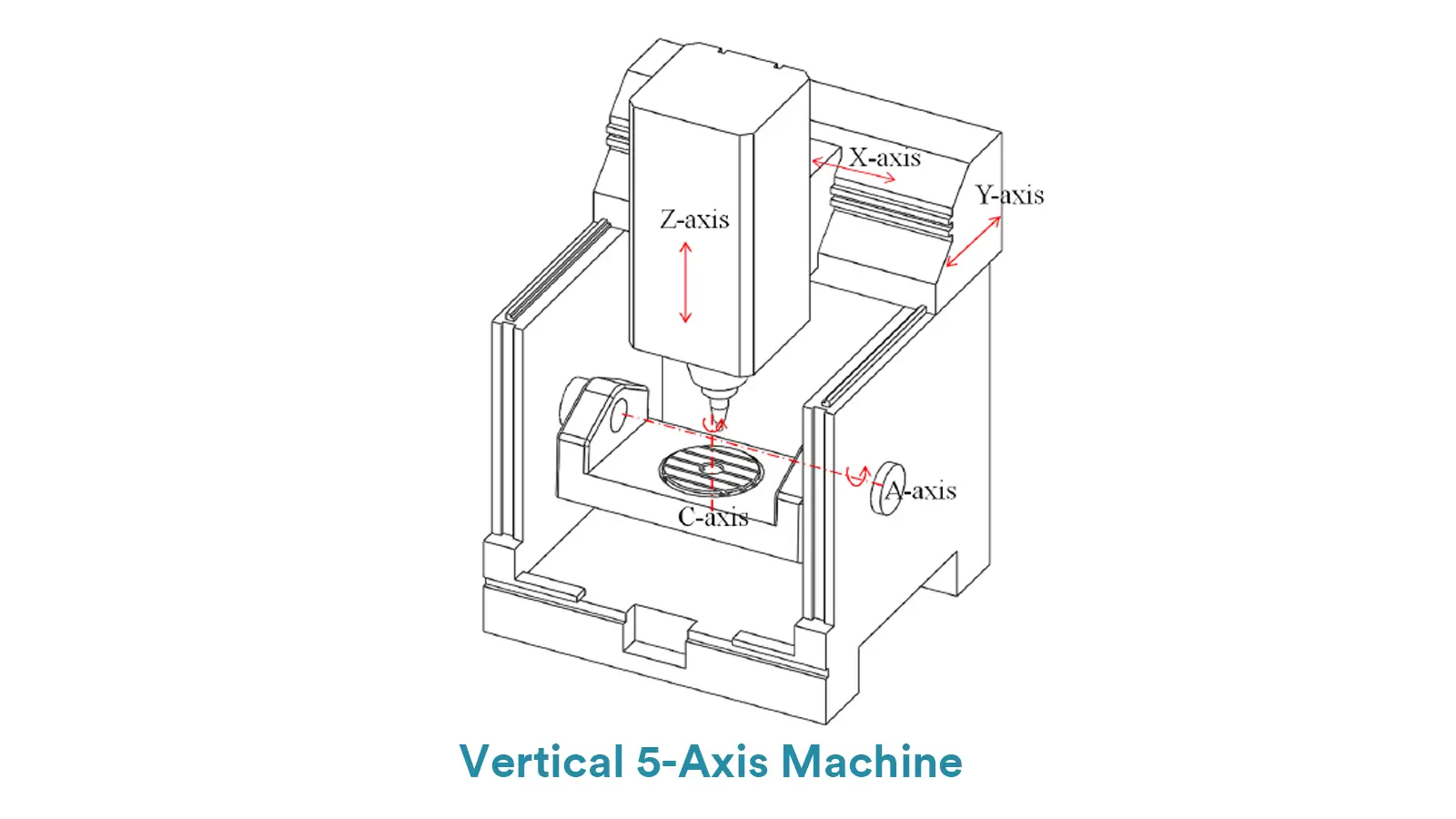

Vertical 5-Axis Machine has compact structure, occupies less space, typically used for precision machining. The spindle and worktable are positioned vertically, and the spindle head can rotate or tilt.

It is suitable for mold manufacturing, precision parts machining, and small part high-precision machining.

2.1.3. Horizontal 5-Axis Machine

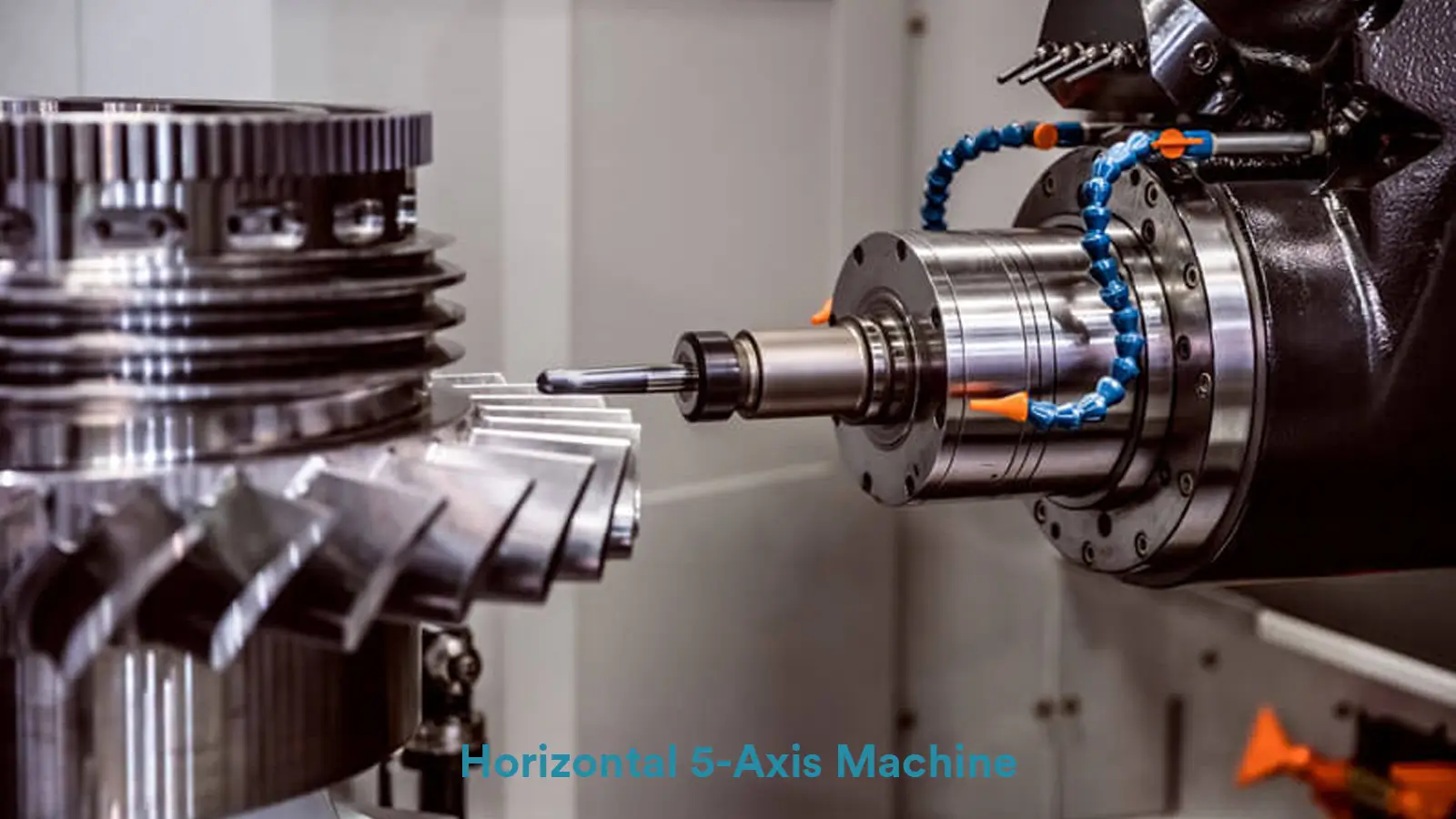

The worktable of horizontal 5-axis machine is positioned on a horizontal plane, offering larger machining space and more clamping options, particularly advantageous for multiple clamping setups.

It is ideal for batch production and machining complex parts, especially when multiple clamping is required.

2.2. Table-Table, Head-Head, and Table-Head5-Axis CNC Machines(Based on Mechanical Structure)

This classification is based on the position of the two rotational axes on the machine—whether the worktable rotates or the spindle head rotates.

2.2.1. Table-Table 5-Axis Machining Center

Table-Table 5 axis machine is also named trunnion-type.

Structural Features of Table-Table:

Both rotational axes (A-axis and C-axis) are integrated into the worktable. The worktable swings back and forth like a cradle (A-axis) and can rotate 360° (C-axis). The spindle head is fixed, and it only moves in the X, Y, and Z directions.

Advantages of Table-Table:

Compact Structure: Takes up less space.

Wide Applicability: Suitable for most common 5-axis machining projects, particularly for mold and medium-sized part machining.

Lower Cost: Compared to other structures, it has lower technical requirements and costs.

Excellent Spindle Rigidity: The fixed spindle head offers outstanding rigidity, making it ideal for heavy-duty cutting.

Minimal Workpiece Weight Impact on Rotation: The worktable rotates rather than the heavy spindle head, which results in lower inertia and more agile and precise motion.

High Precision: The low inertia during worktable rotation provides higher rotational positioning accuracy.

Simplified Programming: Tool Center Point (TCP) calculations are typically more intuitive compared to swivel-head type machines.

Disadvantages of Table-Table:

Limited Workpiece Size: Workpieces are mounted within the cradle framework, which limits their size and weight. Very large parts cannot be machined.

Lower Load Capacity: The worktable’s load capacity is generally lower than that of fixed worktables.

Poor Chip Removal: Chips tend to accumulate on the inclined worktable and fixtures.

Application of Table-Table:

Suitable for machining medium and small parts in industries such as aerospace, automotive, and mold making.

2.2.2. Head-Head 5-Axis Machining Center

Head-Head 5-axis machine is also known as Swivel-Table.

Structural Features of Head-Head:

In swivel-head type machines, both rotational axes (typically the B-axis and C-axis) are integrated into the spindle head. The spindle head carries out tilting (B-axis) and rotating (C-axis) motions to adjust the cutting tool’s orientation.

The workpiece remains fixed on a stationary table and does not move during machining while while the spindle head performs all necessary movements to achieve multi-angle machining.

Advantages of Head-Head:

Exceptional flexibility for machining highly complex geometries and free-form surfaces.

Capable of processing extra-large and heavy workpieces without size limitations due to the fixed table.

Efficient chip evacuation as chips fall directly downward away from the workpiece.

Easier clamping and setup for large components using a simple stationary worktable.

Disadvantages of Head-Head:

Relatively lower spindle rigidity compared to trunnion-type machines due to the rotational mechanism in the spindle head.

Continuous movement of the heavy spindle head may pose challenges in long-term accuracy maintenance.

Not ideal for heavy-duty cutting applications where extreme rigidity is required.

Application of Head-Head:

Ideal for large and heavy parts such as:

Aerospace structural components (wing frames, fuselage sections)

Wind energy parts

Large molds (e.g., for automotive manufacturing)

Marine propellers

Other high-complexity, large-scale precision components

2.2.3. Table-Head 5-Axis Machining Center

Hybrid Type is another name of Table-Head.

Structural Features of Table-Head:

Table-Head 5 axis machining center usually has a rotary table (commonly providing the C-axis) integrated with a tilting spindle head (commonly providing the B-axis or A-axis).

This dual-kinematic structure allows simultaneous adjustment of both the workpiece orientation and the tool angle, offering exceptional machining versatility.

It combines the advantages of both trunnion-style and swivel-head style systems. The workpiece rotates on the table (e.g., C-axis), while the spindle head tilts (e.g., B-axis), enabling full 5-axis simultaneous motion for accessing complex part features from multiple angles.

Advantages of Table-Head:

Delivers high flexibility and precision, making it ideal for complex and high-difficulty parts.

Configurable adaptation to various machining requirements, especially suitable for multi-angle cutting with high accuracy.

Offers an excellent balance between workpiece weight capacity and spindle rigidity.

Cost-effective and highly versatile, making it one of the most popular configurations on the market.

Disadvantages of Table-Head:

Does not provide the extreme spindle rigidity of pure trunnion-type machines.

Does not support as large a workpiece as dedicated swivel-head machines due to table movement constraints.

Represents a balanced but compromise-driven design rather than top-tier specialization.

Applications of Table-Head:

General-purpose 5-axis machining of small to medium-sized parts like aerospace components, medical devices, and precision mold manufacturing.

For better understanding of their features, please check the Comparison of 5-Axis Machine Types: Table-Table vs.Head-Head vs. Table-Head below.

| Feature | Table-Table Type (Trunnion Type) | Head-Head Type (Swivel-Head Type) | Table-Head Type (Hybrid Type ) |

| Motion Method | Workpiece rotates (A/C axes). Spindle head is fixed or has limited tilt. | Spindle head tilts & rotates (B/C axes). Workpiece is fixed. | Combination: Workpiece rotates (e.g., C-axis) + Spindle head tilts (e.g., B-axis). |

| Precision | Good. Ideal for small to medium-sized parts. | High. Excellent for complex geometries and surface finishing. | Very High. Offers maximum flexibility and precision for complex contours. |

| Structural Footprint | Compact. Space-efficient design. | Larger due to complex headstock mechanics. | Moderately large. Balances workspace and machine size. |

| Workpiece Size | Small to Medium. Best for smaller, lighter components. | Large to Massive. No limit from table movement. Ideal for heavy, large parts. | Medium to Large. Versatile for a wide range of part sizes. |

| Primary Applications | Small parts, molds, automotive components, general machining. | Large molds, aerospace structures, wind energy parts, marine components. | Aerospace, medical devices, precision molds, complex prototyping. |

| Cost Efficiency | Cost-effective. Lower initial investment for entry-level 5-axis. | Higher investment. Justified for large-part, complex machining. | Premium price. Offers the best balance of capabilities for advanced applications. |

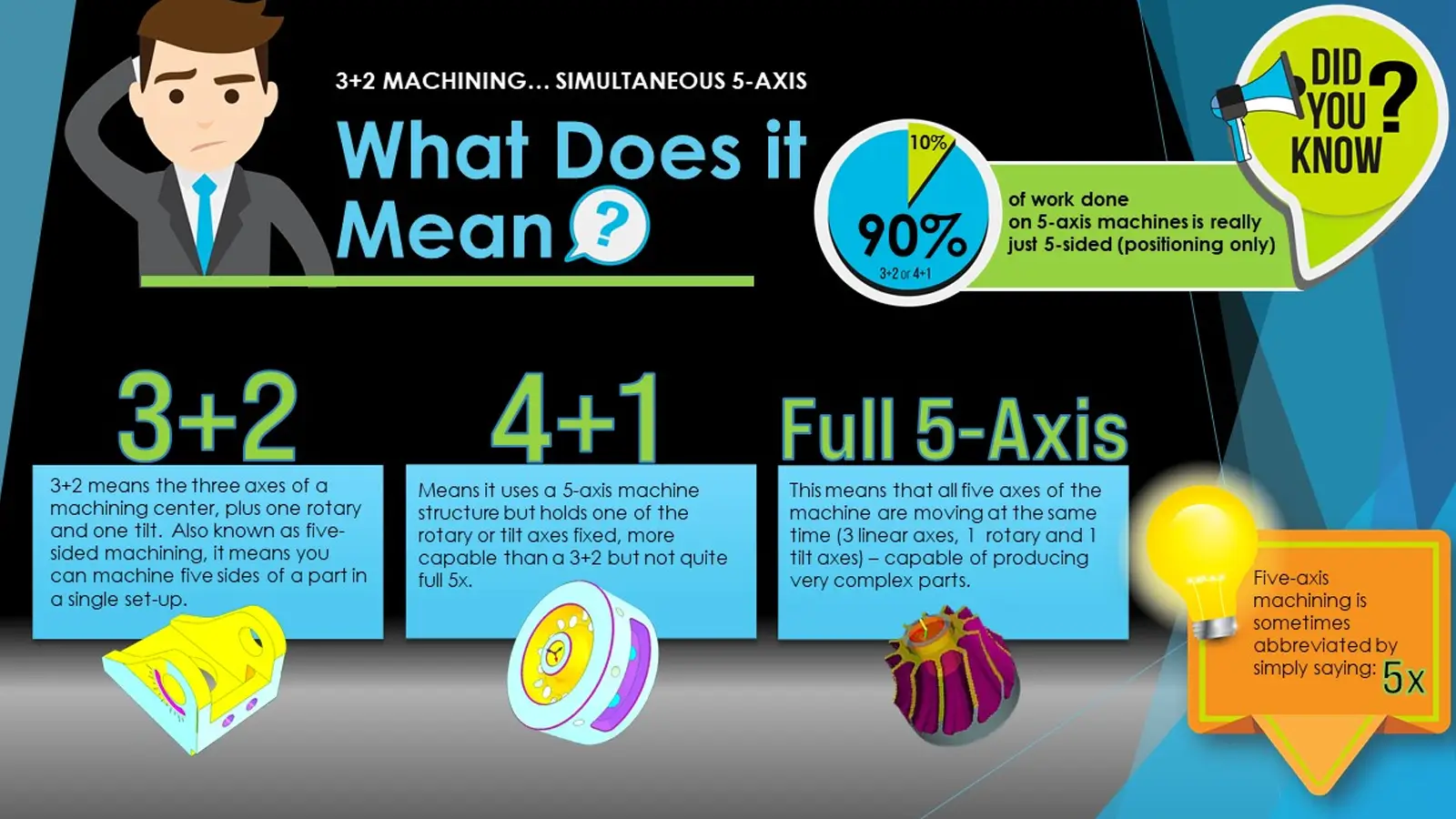

2.3. 3+2-Axis Machining and 5-Axis Simultaneous Machining(Based on Rotational Axis Motion)

This classification is based on how the rotary axes are utilized during machining, which fundamentally impacts the complexity of parts a machine can produce.

Note, 4+1 is seldom in the market, so in this blog we will not talk about it.

2.3.1. 3+2-Axis Machining

Before introducing 3+2-Axis Machining, I would like to share some alternative names commonly used in the industry for this machining method, such as 5-Axis Positioning Machining, 5-Sided Machining, Indexed 5-Axis Machining, and positional 5-axis. These terms all refer to 3+2-Axis machining but emphasize different aspects of its definition.

The following table will help your understanding.

| English Term | Key Focus | Explaination |

| 3+2-Axis Machining | Technical Principle | The preferred term for technical documentation, programming, and precise communication. |

| 5-Axis Positioning Machining (Positional 5-axis) | Functional Movement | Highly versatile; recommended for product introductions and sales materials. |

| 5-Sided Machining | Application Outcome | The best term for demonstrating machine capabilities to clients. |

| Indexed 5-Axis | Operational Method | Professional industry name; very authentic and commonly understood. |

For clarity and precision, we will primarily use the term “3+2-Axis Machining” throughout this guide, as it most accurately describes the technical principle: the independent use of three linear axes and two positioned rotary axes.

Now, let’s explore how 3+2 machining works and why it is such a powerful manufacturing strategy.

Definition:

3+2-axis machining, also known as 5-axis positional machining, is a manufacturing process where a CNC machine utilizes its three linear axes (X, Y, Z) and two rotational axes (A/B) for positioning, but without continuous simultaneous movement of all five axes. The rotary axes tilt the workpiece or cutting tool to a fixed angle and remain locked during machining, while cutting is performed solely through the linear axes.

How It Works:

Positioning: The rotary axes (e.g., A and C) adjust the workpiece or tool to a predefined optimal angle.

Locking: The rotational axes are fixed in place during cutting.

Machining: The machine operates like a standard 3-axis system, using only X, Y, and Z movements to remove material.

Key Features:

No RTCP Required: The CNC system does not need advanced Real-Time Tool Center Point control, simplifying programming and operation.

Improved Rigidity: Locked rotary axes enhance stability, enabling heavier cuts and higher feed rates.

Simplified Programming: Often programmed using 3-axis CAM software, with multiple setups for different angles.

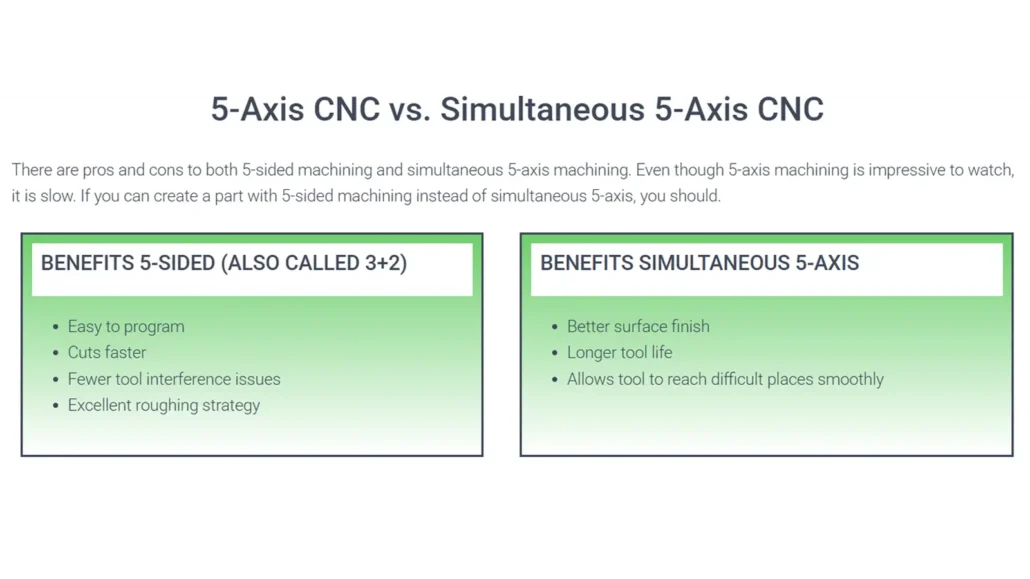

Advantages:

Cost-Effective: Lower machine and programming costs compared to full 5-axis simultaneous machining.

Reduced Cycle Times: Faster machining due to simplified toolpaths and heavier cutting capabilities.

Shorter Tools: Tilting allows use of shorter, more rigid tools, reducing vibration and improving surface finish.

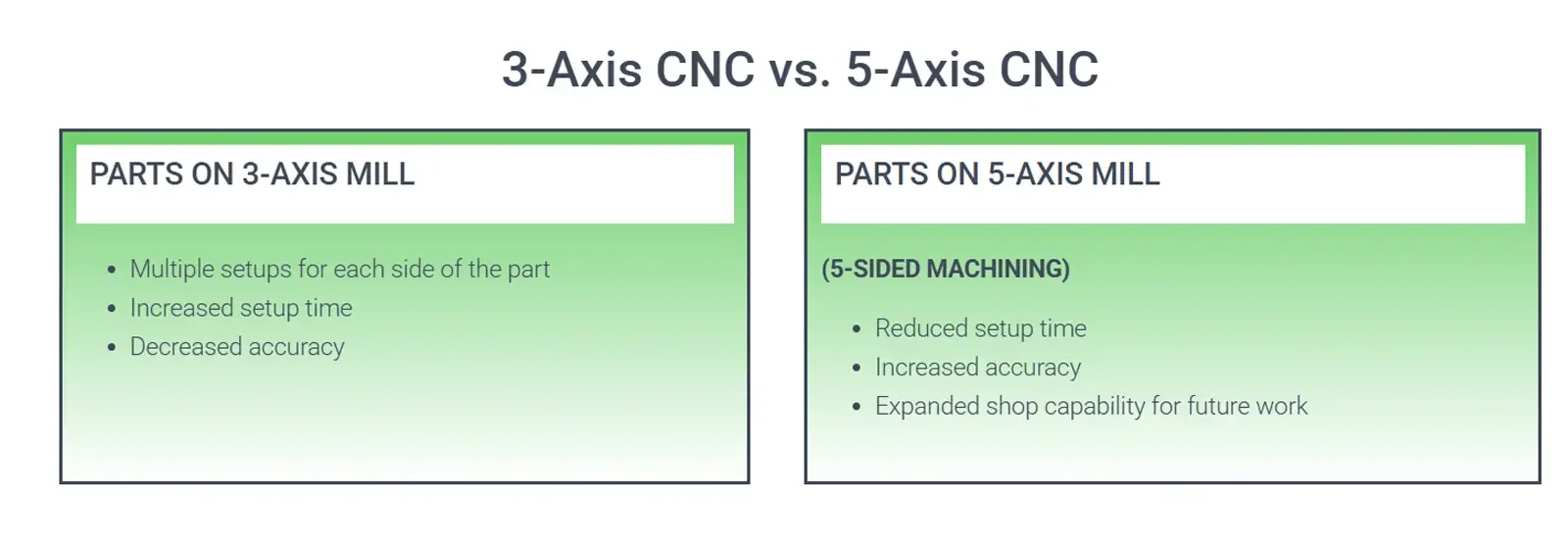

Single-Setup Processing: Machines multiple sides of a part without re-fixturing, minimizing errors.

Limitations:

Limited Complexity: Cannot machine continuous complex curves or freeform surfaces.

Lower Flexibility: Less suitable for highly intricate geometries requiring dynamic tool orientation.

Applications:

Multi-sided machining of parts (e.g., mold cavities, brackets).

Angled features (e.g., drilled holes, inclined planes).

Industries: Automotive, general machining, mold manufacturing.

3+2-axis machining is a cost-efficient, high-rigidity alternative to full 5-axis machining, ideal for multi-angle positioning and single-setup production of parts with moderate complexity. It bridges the gap between 3-axis and 5-axis capabilities, offering simpler programming and faster cycles for angled features.

2.3.2. 5-Axis Simultaneous Machining

In CNC machining industry, there are many common and accepted alternative names for 5-Axis Simultaneous Machining, like Full 5-Axis Machining, 5-Axis Contouring, Continuous 5-Axis Machining,RTCP Machining , TCP Machining, True 5-Axis Machining, 5-Axis Milling.

| English Term | Key Focus | Usage Suggestion |

| 5-Axis Simultaneous Machining | Coordinated Motion | The gold standard for technical precision. |

| Full 5-Axis Machining | Maximum Capability | Excellent for marketing and general descriptions. |

| 5-Axis Contouring | Complex Geometry Output | Ideal when discussing specific applications like airfoils or molds. |

| Continuous 5-Axis Machining | Uninterrupted Motion | Highlights process continuity and surface finish. |

| RTCP Machining | Enabling Technology | For technical discussions about CNC control capabilities. |

| True 5-Axis Machining | Distinction from 3+2 | Useful for clarifying capabilities, but can be informal. |

We will use 5-Axis Simultaneous Machining in this blog.

Definition:

5-Axis Simultaneous Machining is an advanced CNC process where all five axes (three linear axes X, Y, Z and two rotational axes, e.g., A and B/C) move in a continuously coordinated motion during machining. This enables dynamic adjustment of the cutting tool’s orientation and position relative to the workpiece, ensuring optimal engagement with complex geometries at all times.

How It Works:

RTCP Activation: The CNC program activates the RTCP (Rotational Tool Center Point) function, enabling real-time compensation for tool tip positioning as rotary axes move.

Coordinated Motion: The CNC controller simultaneously orchestrates all five axes to maintain precise tool tip trajectory and orientation.

Continuous Cutting: The tool smoothly follows contoured surfaces, with the rotary axes adjusting dynamically to avoid collisions and optimize cutting conditions.

Key Technology:

RTCP (TCPC in some systems): The core enabling technology that automatically calculates and compensates for tool center point shifts caused by rotary axis movements.

The true 5-axis simultaneous machining capability depends on whether the CNC system supports advanced 5-axis control functions. The most important feature is RTCP (Rotation Tool Center Point) or similar functions (often called RPCP – Rotation Around Part Center Point in German/Japanese systems).

Advantages:

Unmatched Complexity: Capable of machining highly complex freeform surfaces (e.g., impellers, turbines, medical implants, propellers).

Superior Surface Finish: Maintains consistent cutting conditions and tool orientation, reducing hand polishing and ensuring exceptional surface quality.

Single-Setup Efficiency: Completes intricate parts in one clamping, minimizing errors and handling time.

Optimal Tool Utilization: Enables the use of shorter, more rigid tools via continuous orientation adjustment, improving stability and material removal rates.

Challenges:

Complex Programming: Requires advanced CAM software and rigorously validated post-processors.

High Machine Requirements: Demands CNC systems with high processing power, precise servo dynamics, and rigid mechanical structures.

Elevated Costs: Significant investment in machinery, software, and specialized expertise.

Applications:

Aerospace components (blisks, airfoils, engine parts)

Medical implants (prosthetics, bone structures)

Automotive turbos and complex molds

High-precision defense and energy components

5-Axis Simultaneous Machining represents the pinnacle of CNC technology, enabling the production of highly complex, free-form geometries with exceptional precision and surface finish. Essential for aerospace, medical, and advanced manufacturing industries, it leverages RTCP functionality to achieve unmatched accuracy and efficiency in a single setup.

For your better understanding of the differences between 3+2 Positioning Machining and 5-Axis Simultaneous Machining, see the table below.

| 3+2 Positioning Machining vs. 5-Axis Simultaneous Machining | ||

| Feature | 3+2 Positioning Machining | 5-Axis Simultaneous Machining |

| Motion Type | 3 linear axes (X, Y, Z) + 2 rotational axes (A, B) for positioning | 5 axes (X, Y, Z, A, B) moving simultaneously |

| Precision | Suitable for simpler or lower-precision parts | High precision, suitable for complex shapes and high-precision requirements |

| Operational Complexity | Relatively simple, easier to operate and program | More complex, requires higher skill and programming capabilities |

| Machining Efficiency | Faster machining speed due to no real-time simultaneous motion | Slower machining speed, but can handle more complex workpieces |

| Cost | Lower cost, suitable for budget-constrained production environments | Higher cost, suitable for high-precision and high-value parts |

| Applications | Molds, brackets, simple curved parts | Aerospace, automotive, medical, complex molds, etc. |

| Setup Frequency | Requires multiple setups for different angles | Typically only requires one setup, reducing errors |

| Flexibility | Suitable for simpler geometries, lower precision | Offers greater flexibility, capable of handling complex 3D shapes |

3. Why is 3+2-Axis Machining More Popular in China?

Previously, we have talked about 3+2-Axis machining and 5-axis simultaneous machining. In China, I have visited hundreds of CNC machining factories in Guangdong, Zhejiang and other cities during my past jobs. It is true that more and more Chinese CNC machining factories have already purchased or are preparing to purchase 5-axis milling machine, but most of them are 3+2.

Why? The answer is because of the cost. Now we will compare more.

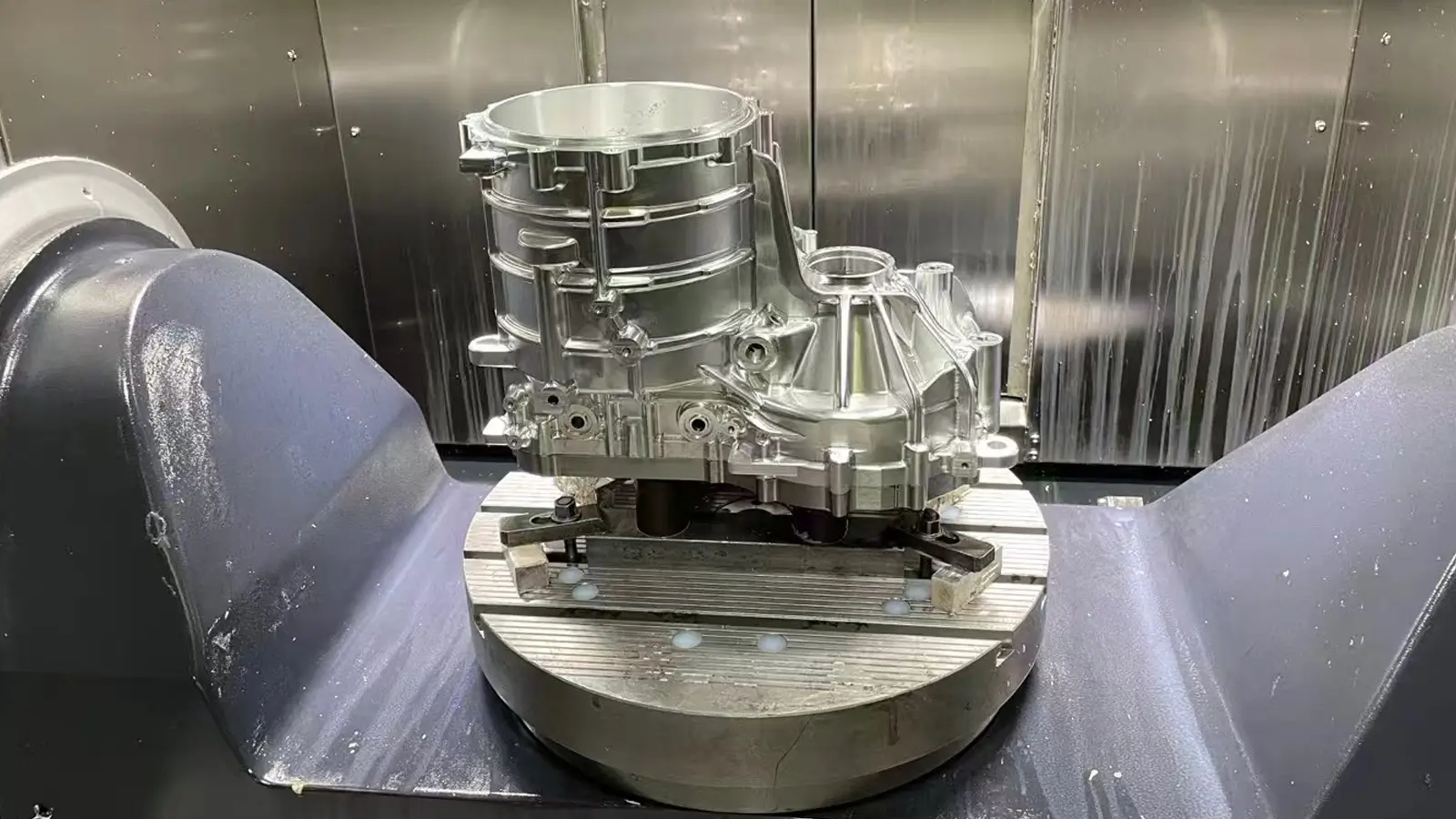

Below is a photo showing one China CNC machining factory with 3+2 axis machines.

3.1. 3+2-Axis VS 5-axis Simultaneous Machine Cost

From a financial perspective, the base price of a true 5-axis simultaneous machining center is typically 1.5 to 2.5 times higher, or even more, than that of a 3+2 positioning machine with the same travel distance.

The significant price difference between 5-axis simultaneous and 3+2 positioning machines are from fundamental differences in hardware, software, and control technology.

3.1.1. CNC Control System Comparison

This is the most critical difference.

3+2 machining center requires only a standard 3-axis control system with indexing capability. The rotary axes move to a commanded position and lock, after which the control logic is identical to a 3-axis machine.

While 5-Axis simultaneous machining center must be equipped with a high-end CNC system (e.g., Siemens 840D, Heidenhain TNC 640, Fanuc 31i-B) and requires the RTCP (Rotational Tool Center Point) function option.

This software feature (often a costly add-on) requires the controller to perform complex real-time mathematical calculations to compensate for tool tip displacement caused by rotary movement. The RTCP system is inherently expensive.

3.1.2. Mechanical Structure & Dynamics Comparison

The mechanical parts of 5-axis simultaneous machine need to be built to a much higher standard to allow for fast, smooth, and precise movement of all five axes at the same time.

Rigidity, Damping & Thermal Stability: During 5-axis continuous machining, all axes are in motion. Any minimal vibration, deflection, or thermal expansion translates directly into a machining error.

Therefore, core components like the bed, guides, ball screws, and bearings must be built to much higher specifications (e.g., polymer concrete beds, full closed-loop feedback with scales, liquid-cooled ball screws, hydrostatic guides) to ensure extreme dynamic rigidity and thermal stability. These components are extremely costly.

Rotary Axis Accuracy: The rotary axes on a 3+2 machine are primarily for positioning and have relatively lower accuracy and rigidity requirements.

The rotary axes on a 5-axis machine are in constant motion during cutting and must be high-precision, high-rigidity units driven by torque motors or worm gears with high-resolution encoders. Their manufacturing and assembly costs are exponentially higher.

3.1.3. Servo Drives & Motors Comparison

The drive system of 3+2 machine only needs enough power to move the rotary axes to a position and hold them there.

5-Axis machine requires more powerful and responsive servo drives and motors to handle constantly changing loads and accelerations during continuous motion.

The system must manage complex kinematic transformations and feedforward control to prevent trajectory errors or vibrations during high-speed interpolation. The performance and cost of this drive system are far superior.

3.1.4. Software & Post-Processor Comparison

CAM Software: 3+2 programming can use relatively inexpensive or even traditional 3-axis CAM software. 5-axis simultaneous machining mandates advanced 5-axis CAM modules (e.g., HyperMill, PowerMill, NX CAM), which are expensive licenses themselves.

Post-Processor: This is the key link that converts the CAM toolpath into machine-readable G-code. A 3+2 post-processor is relatively simple. A 5-axis simultaneous post-processor is extremely complex, requiring perfect alignment with the specific machine’s mechanical structure, control system, and RTCP algorithms. Its development and validation are costly, and an error can cause a severe crash.

3.1.5. R&D & Integration Comparison

Developing a high-performance 5-axis machining center requires massive R&D investment, involving the deep integration of multiple advanced fields like mechanical engineering, electrical engineering, software, and control algorithms. This technological barrier and R&D cost is naturally reflected in the final product’s price.

We can think of their difference like this:

A 3+2 Machine ≈ A high-performance 3-axis machine + A precision index table.

A 5-Axis Simultaneous Machine ≈ A supercomputer-level CNC system + A mechanically superior platform with exceptional dynamics + High-precision, high-speed rotary axes + Complex calibration and compensation technology + Advanced software, all deeply integrated.

It is not simply about “adding two moving axes”; it represents a fundamental leap in technology, alike upgrading from a “feature phone” to a “smartphone.” This shift encompasses a comprehensive amalgamation of advanced engineering and integrated costs.

Consequently, the 1.5 to 2.5 times (or greater) price differential is a direct reflection of the immense gap in technological sophistication and performance capability.

3.2. 3+2-Axis VS 5-axis Simultaneous Machining Programming

3.2.1. 3+2-Axis Machining: programming multiple fixed orientations

The core concept of 3+2-Axis Machining programming is position then cut. The programmer’s primary task is to define multiple fixed machining orientations.

Workflow of 3+2-Axis Machining programming:

Define Orientation: For each desired tilt angle, the programmer creates a new Work Coordinate System (WCS) or machining coordinate system. This is the digital equivalent of physically re-fixturing the part at a new angle.

Generate Toolpath: The CAM software then generates a standard 3-axis tool path within each of these defined coordinate systems. The tool moves only linearly (X, Y, Z).

Post-Process: The post-processor outputs G-code that first commands the rotary axes (e.g., A90. C45.) to move to the programmed position and lock. It then follows with the standard linear G-code for the 3-axis cut.

Repeat: This process is repeated for each orientation.

We can say 3+2-Axis Machining programming is essentially a collection of multiple 3-axis programs, strung together by rotary axis positioning commands (A, C codes).

3.2.2. 5-Axis Simultaneous machining programming

The 5-Axis Simultaneous machining programming is continuous motions. The programmer’s core task is to define the ideal path for the Tool Center Point (TCP) and the laws for its continuous, smooth variation of tool orientation.

Workflow 5-Axis Simultaneous Machining Programming

Define Geometry & Strategy: The programmer works on the complete 3D model, selecting advanced 5-axis toolpath strategies like swarf cutting, morphing, or flowline machining.

Set Control Parameters: The programmer defines how the tool orientation should behave—keeping it normal to a surface, leading/lagging by an angle, or avoiding collisions automatically.

Compute Motion: The CAM software performs complex calculations. For every point along the toolpath, it determines the exact, simultaneous position required for all five axes (X, Y, Z, A, B/C) to ensure the TCP stays on its precise trajectory and the tool orientation follows the defined law.

Post-Process with RTCP: A sophisticated, machine-specific post-processor generates the final code. Crucially, this code often only specifies the TCP path and orientation vectors (I, J, K). The machine’s CNC control, with its RTCP function, automatically calculates the individual axis movements in real-time to achieve the commanded motion.

5-Axis Simultaneous machining programming is a true, complex motion program where all five axes are continuously interpolating in perfect coordination.

3.2.3. Practical Programming

3+2-Axis Programming

This is where all 5 axis move simultaneously under Gcode control to machine the part. In this example it will move all axis to specific locations and all axis will arrive simultaneously, crating a curved surface.

3+2 Programming

This is where the material is rotated into position using the A & B axis and are locked in place while 3 axis machining using the XY & 2axes machining is performed before rotation to a new position where it is again locked in position and more machining is performed.

While this Gcode looks similar to the previous example it will produce a very different result.

From the comparison of programming principles above, it’s clear that 5-axis simultaneous machining programming is more complicated. There are more factors to consider, and it demands a higher level of skilled programmers.

3.3. 3+2-Axis VS 5-axis Simultaneous Machining Labor Cost

There is no doubt that 5-Axis Simultaneous Machining has significantly higher technical requirements on both programmers and machine operators.

Below is the table of requirements for programmers.

| Programmer Requirements: 3+2 Positioning Machining VS 5-Axis Simultaneous Machining | |||

| Aspect | 3+2 Positioning Machining | 5-Axis Simultaneous Machining | Conclusion |

| Core Mindset | Geometric positioning mindset: Decomposing complex parts into multiple simple, fixed-angle 3-axis machining tasks. | Kinematic and dynamic mindset: Considering the overall behavior of the tool during continuous motion, including toolpath, tool orientation, collision avoidance, and varying cutting loads. | 5-axis requires a higher level of abstract thinking and spatial imagination. |

| Software Skills | Standard 3-axis CAM software or 3+2 modules are sufficient. Main tasks involve creating coordinate systems and generating 3-axis toolpaths. | Must use advanced 5-axis CAM modules (e.g., PowerMill, HyperMill, NX). Mastery of complex 5-axis strategies (e.g., Swarf, Morphing) is essential. | The software requirement and complexity for 5-axis are far greater than for 3+2. |

| Knowledge Base | Requires understanding of rotary axis positioning and coordinate transformations. | Requires in-depth knowledge of machine kinematics (e.g., head-head, table-table, hybrid), RTCP/RPCP principles, post-processing customization, and material removal dynamics. | 5-axis demands deeper and broader theoretical knowledge. |

| Debugging & Validation | Program validation is relatively straightforward, mainly checking for gouging in each fixed orientation. | Programs must undergo comprehensive collision checking (toolholder, spindle, workpiece, fixture) via simulation software, ensuring smooth and stable tool axis motion. The process is complex and time-consuming. | 5-axis involves significantly higher debugging risks and validation requirements. |

Below are the differences in the operator requirements.

| Machine Operators Requirements:3+2 Positioning Machining VS 5-Axis Simultaneous Machining | |||

| Aspect | 3+2 Positioning Machining | 5-Axis Simultaneous Machining | Conclusion |

| Core Skills | Workpiece setup and alignment: Ensuring the part is machined correctly at each angle. Process management: Managing the machining sequence across multiple coordinate systems. | Real-time monitoring and decision-making: Not only monitoring the cutting state but also anticipating risks (e.g., collisions, vibrations) arising from complex 5-axis motion. | The focus for 5-axis operators shifts from “execution” to “monitoring and decision-making.” |

| Knowledge Base | Requires familiarity with machine indexing positioning and standard 3-axis machining workflows. | Must thoroughly understand concepts like RTCP functionality, tool coordinate systems, and tool tip tracking. Needs to interpret and preliminarily assess the rationality of 5-axis tool axis movements. | 5-axis operators must understand the underlying principles, not just the interface. |

| Setup & Debugging | Offsets (tool setting) are primarily in the Z-axis. Each coordinate system may require a separate Z-value setting. | Tool setting and setup are typically based on a single coordinate system (tool tip), but all parameters (tool length, radius, RTCP settings) must be absolutely accurate. Even a minor error can cause a major collision. | 5-axis setup has extremely low error tolerance, requiring meticulous attention and precision. |

| Troubleshooting | Issues are usually straightforward, such as tool wear or coordinate errors. | Must handle anomalies during continuous motion (e.g., sudden vibrations, unusual noises) and quickly determine whether the cause is programming, tooling, or machi | 5-axis operators need stronger problem-diagnosis capabilities. |

Whether in programming or operation, the technical requirements for 5-axis simultaneous machining far exceed those for 3+2 positioning machining. Consequently, the salary expectations for workers in continuous 5-axis machining are significantly higher.

Taking CNC machining factories in Shenzhen, Guangdong, China as an example:

The monthly salary for 3-axis programmers ranges from ¥8,000 to ¥12,000 RMB.

For 3+2 positioning machining programmers, it ranges from ¥10,000 to ¥15,000 RMB.

For continuous 5-axis simultaneous machining programmers, it can reach ¥15,000 to ¥20,000 RMB.

Correspondingly, the wages for machine operators are approximately:

¥6,000 – ¥7,000 RMB for 3-axis operators,

¥8,000 – ¥10,000 RMB for 3+2 operators,

¥10,000 – ¥12,000 RMB for 5-axis simultaneous operators.

These differences in labor costs are also substantial.

3.4. 3+2-Axis VS 5-axis Simultaneous Machining Workshop Requirement

Many 5-axis simultaneous machining centers have higher environmental requirements, demanding temperature and humidity control, as well as vibration-resistant foundations, to ensure machining quality and precision.

These cause higher operational costs for factories. It’s also why top manufacturing workshops focused on high-precision aerospace, medical, and optical fields often look like laboratories rather than traditional factories.

Based on the above factors, it is clear that the investment required for continuous 5-axis equipment is substantial, while the cost of a 3+2 configuration is relatively low. Many Chinese machining factories choose to upgrade their existing 3-axis machine to 3+2 machine by installing indexing rotary tables, with the cost of adding such a table ranging from 50,000 to 80,000 RMB.

| Full cost Comparision: 3+2 Positioning Machining VS 5-Axis Simultaneous Machining | ||

| Cost Category | 3+2 Positioning Machining | 5-Axis Simultaneous Machining |

| Machine Tool Hardware | $$$ | $$$$$ |

| CNC System | $$ | $$$$$ |

| CAM Software | $$ | $$$$ |

| Post Processor | $ | $$$ |

| Simulation Software | (Optional) | $$$ |

| Maintenance & Calibration | $$ | $$$$ |

| Labor Costs | $$ | $$$$ |

| Factory Environment Cost | $ | $$$ |

By the way, for the classification of 5-axis machines and their approximate prices, we recommend visiting the Haas website. Their classification is very detailed, and they also provide starting prices. Additionally, Haas is a well-known brand in the U.S., and we will mention this later.

4. Top 5 Benefits of 5 Axis CNC Machining

5-axis machining provides the perfect solution for high-end manufacturing challenges.

4.1. Realization of Complex Geometries

This is the most significant advantage of five-axis machining. It effortlessly handles parts that are simply impossible to machine with three-axis equipment.

For example, components such as aerospace engine impellers, turbines, and turbocharger scroll housings in the automotive industry are extremely difficult to produce with three-axis machining. Five-axis technology makes this achievable.

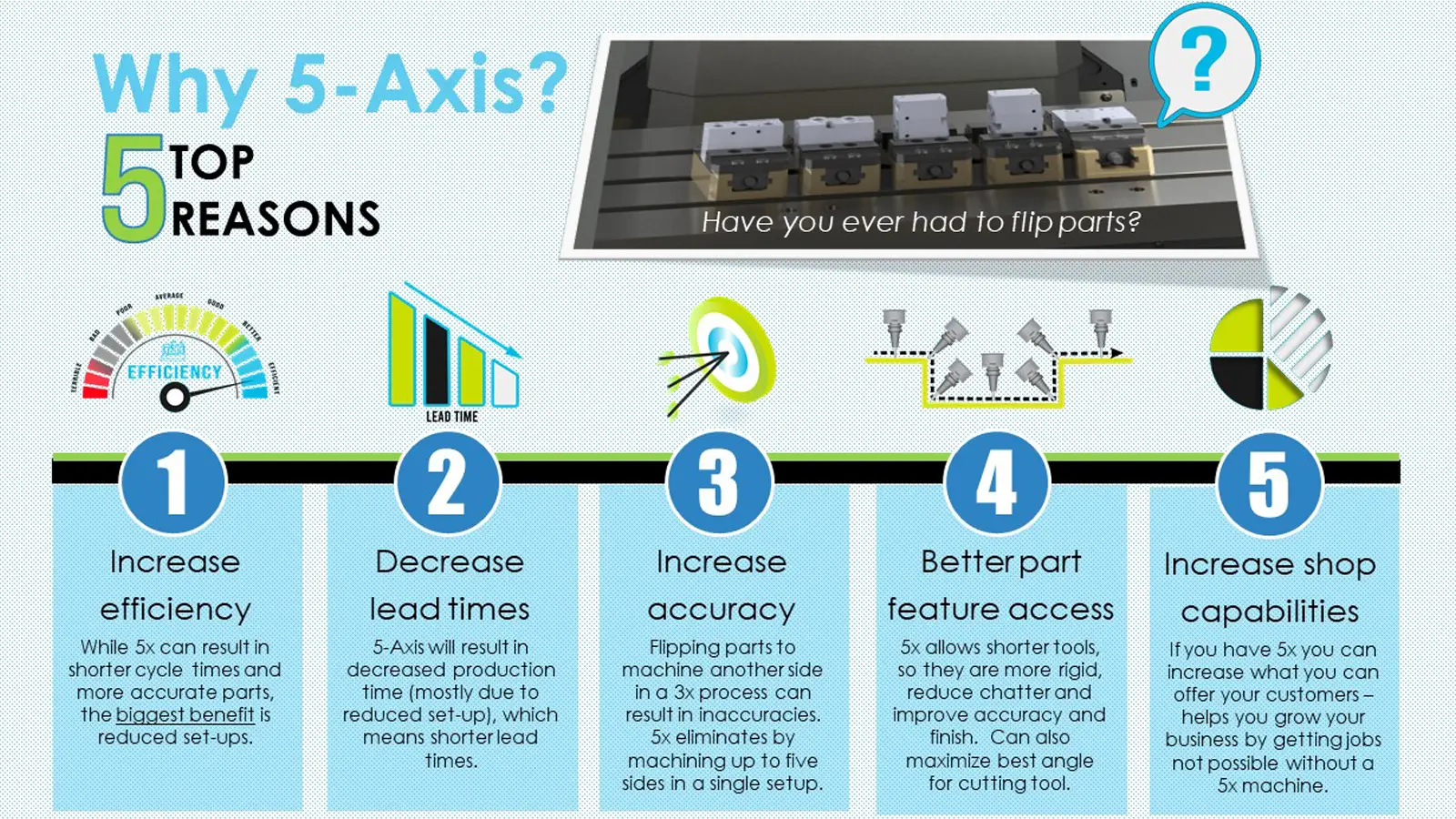

4.2. Ultra-High Precision

Single setup and complete machining are the most critical factors in achieving high precision.

In three-axis machining, a part requires multiple repositioning and reclamping to complete all surfaces, each time introducing new positioning errors.

Five-axis machining, by rotating the worktable or spindle head, allows the tool to approach the workpiece from all angles. Nearly all—or even all—machining can be completed in a single setup, entirely eliminating repetitive positioning errors and ensuring extremely high dimensional accuracy and geometric tolerances.

4.3. Significant Improvement in Production Efficiency

Reduced Setup Time: A single setup saves substantial time spent on part removal, flipping, repositioning, and recalibration.

Streamlined Production Process: Process consolidation reduces waiting time and logistics costs associated with transferring parts between different machines.

Use of Shorter Tools: By tilting the workpiece or tool head, shorter and more rigid tools can be employed. Shorter tools experience less vibration, allowing for higher cutting parameters (greater depth of cut, faster feed rates), thereby significantly reducing cutting time.

Optimized Tool Paths: Five-axis simultaneous movement enables more efficient and shorter tool paths, minimizing non-cutting movements and further enhancing efficiency.

4.4. Superior Surface Finish

Five-axis simultaneous machining enables the tool’s side edge to maintain the optimal cutting angle when engaging the workpiece (known as “tool side cutting”). This avoids the poor cutting effects associated with the low-speed cutting zone at the tip of a ball-nose tool, resulting in a smoother surface finish. Consequently, the need for subsequent manual polishing is reduced or even eliminated.

4.5. Reduced Manual Intervention

Five-axis machining centers are highly automated, typically equipped with advanced CNC systems and automation technologies. This minimizes manual intervention, enhancing the stability and consistency of the machining process.

5. Industries with 5-Axis Machining Service

5.1. Aerospace Industry

Aerospace components often feature complex geometries and strict tolerance requirements. Five-axis machining provides the capability to process complex curved surfaces with high precision. It can effectively handle thin-walled structures, precision turbine blades, intake ducts, and other complex parts, ensuring high strength and durability.

5.2. Automotive Industry

In the automotive industry, five-axis machining is used to manufacture complex engine components, turbochargers, braking systems, and precision body molds. It enables the machining of multiple surfaces and complex curves in a single workpiece clamping, significantly improving production efficiency and part accuracy.

5.3. Medical Industry

Medical devices require extremely high precision and excellent surface quality. Five-axis machining is used to produce customized orthopedic implants, dental restorations, and other medical parts. These products often involve complex geometries and precise dimensional requirements, and five-axis machining ensures stable and high-precision results.

5.4. Mold Manufacturing Industry

Mold components often require high-precision holes, complex cavities, and intricate surface shapes. Five-axis machining efficiently produces these complex forms, eliminating the need for multiple clamping and machining steps, thereby enhancing production efficiency.

5.5. Defense and Military Industry

In the defense and military sectors, five-axis machining is used to manufacture precision weapons and equipment components, particularly those with complex geometries and high-strength requirements, such as parts for unmanned aerial vehicles (UAVs).

6. Typical 5-Axis CNC-machined Parts

6.1. Aerospace Engine Blisk (Bladed Disk)

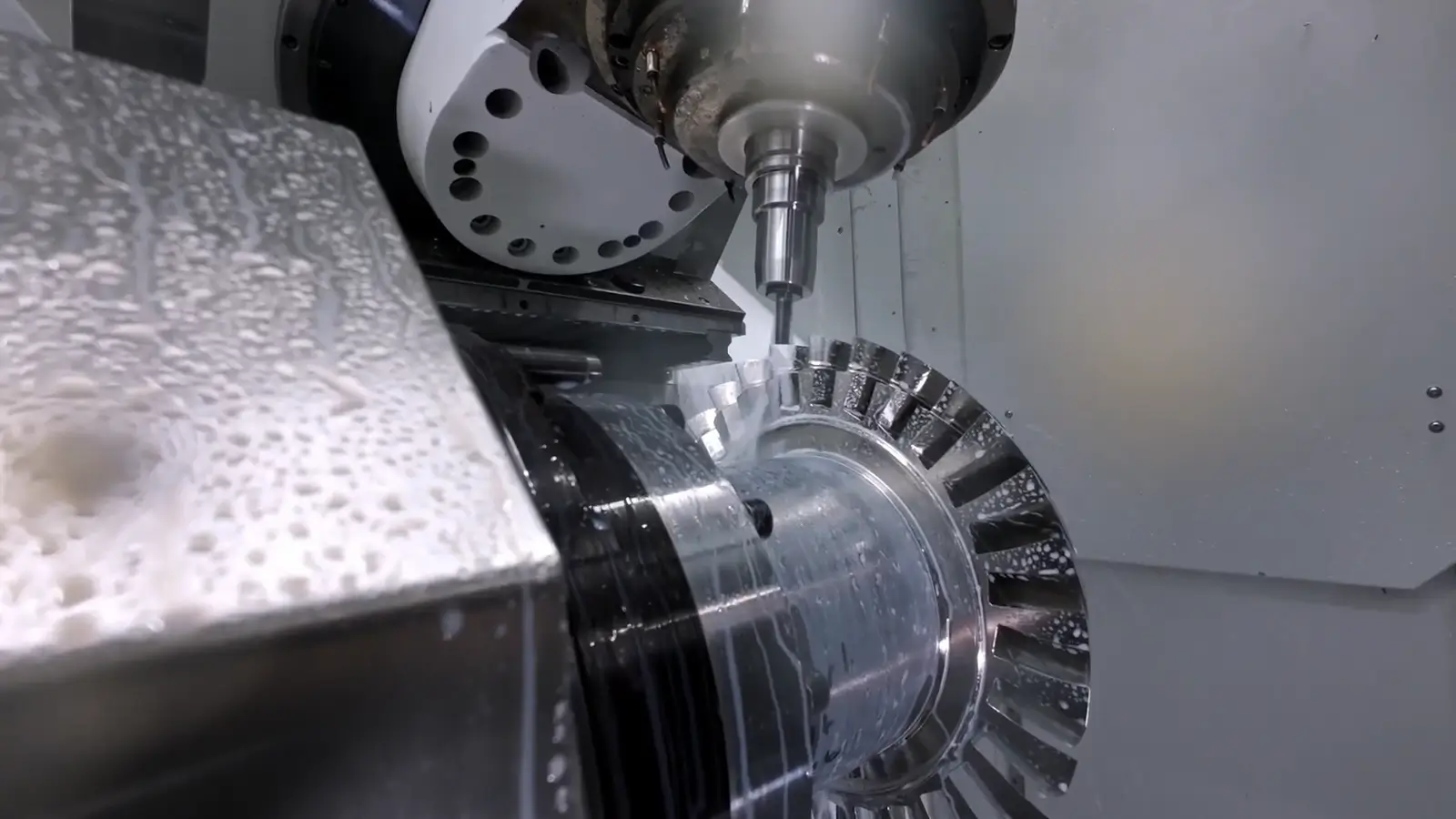

Aerospace Engine Blisk (Bladed Disk) is the typical 5 axis CNC machining part.

A blisk (bladed disk)—an integral component in jet engines—combines the turbine disk and blades into a single unit, eliminating the need for assembly. Its blades feature intricate free-form surfaces with narrow, deep channels between them.

Machined from challenging materials like titanium or nickel-based superalloys, which offer high strength and toughness, these parts require extreme precision. Even minor defects can compromise aerodynamic efficiency and safety, making exceptional accuracy and surface finish critical.

5-axis CNC machining excels at producing blisks in a single setup.

Here’s how continuous 5-axis machining delivers perfect bladed disk results:

Steps:

Single Setup: The raw blank is securely fixed on the rotary table of a 5-axis machine.

Swarf Machining: Simultaneous 5-axis movement maintains the optimal contact angle between the tapered ball-nose cutter and the blade’s complex curvature. This avoids cutting at the tooltip (where cutting speed is zero), significantly improving efficiency, extending tool life, and achieving superior surface quality.

Collision Avoidance: The machine’s rotary axes dynamically adjust the tool orientation, allowing long-reach tools to access narrow blade channels without interfering with adjacent blades.

6.2. Automotive Wheel Hubs

5-axis machining, particularly using the 3+2 indexing method, is the industry standard for producing high-performance, aftermarket, and forged luxury wheels. It is the preferred solution for manufacturing intricately designed hubs.

A wheel hub is far from a simple rotational part. It comprises multiple features machined on different planes: stylish front spokes, a complex barrel structure on the back, bolt holes, a center bore, and a valve stem hole.

Additionally, deep pockets or windows between spokes are challenging to machine with 3-axis systems using extended tools, which are prone to vibration, compromising precision and finish.

As a safety-critical component, the wheel hub’s mounting face and center bore must meet extremely tight dimensional and concentricity tolerances to ensure perfect vehicle fitment and dynamic balance. The visual surface—especially the front—requires a flawless finish, free of tool marks or defects.

How 5-Axis (3+2) Machining Produces Wheel Hubs:

The 3+2 method is mainstream in wheel manufacturing, enabling complete machining in one setup.

The forged or cast wheel blank is mounted on the machine’s rotary table.

The rotary axes (A/C) position each surface perpendicular to the spindle for optimal machining.

Machining the Back: The back is rotated into position for roughing and finishing the barrel, milling the mounting face, and drilling/tapping bolt holes.

Machining the Front: The part is rotated 180° to machine the front side. All spoke faces, sides, undercuts, and the rim lip are completed in a single operation.

For high-performance, lightweight, and custom aftermarket wheels, 5-axis machining (especially 3+2) is the undisputed standard. It transforms a solid billet of aerospace-grade aluminum into a strong, lightweight, and aesthetically precise component through subtractive manufacturing.

Other classic examples of 5-axis machined parts include tire molds, automotive lamp molds, motor housings (e.g., turbochargers). In our other blog, we will explore large part 5-axis machining VS small part 5-axis machining and shared more 5-axis CNC machining parts made by ECOREPREP.

7. Top 5 5-axis CNC Machine Brands in The World

7.1. Top 3 German 5-Axis Machine Manufacturers

TOP 1: DMG MORI DMG MORI offers an exceptionally diverse product lineup, ranging from vertical and horizontal machining centers to multi-tasking turn-mill centers, covering almost all forms of 5-axis machining. Its iconic MONOBLOCK series, featuring a monolithic bed design, is highly regarded in industries such as mold making, aerospace, and precision component manufacturing.

DMG MORI offers an exceptionally diverse product lineup, ranging from vertical and horizontal machining centers to multi-tasking turn-mill centers, covering almost all forms of 5-axis machining. Its iconic MONOBLOCK series, featuring a monolithic bed design, is highly regarded in industries such as mold making, aerospace, and precision component manufacturing.

Representative Models: DMU 50, DMU 80 P

TOP 2: GROB GROB is an undisputed leader in specialized sectors, particularly automotive powertrains. It is the global leader in providing production systems for engine blocks, cylinder heads, and electric vehicle motor housings to automotive manufacturers. GROB’s universal 5-axis machining centers often feature horizontal 4-spindle or 5-spindle configurations and inverted structures, delivering unparalleled production efficiency.

GROB is an undisputed leader in specialized sectors, particularly automotive powertrains. It is the global leader in providing production systems for engine blocks, cylinder heads, and electric vehicle motor housings to automotive manufacturers. GROB’s universal 5-axis machining centers often feature horizontal 4-spindle or 5-spindle configurations and inverted structures, delivering unparalleled production efficiency.

Representative Models: GROB G350, GROB G550

TOP 3: HERMLE A German family-owned enterprise, HERMLE sets the technological benchmark for high-performance 5-axis machining centers. It is the ultimate choice for top-tier users who require extreme precision, optimal dynamic performance, and exceptional thermal stability.

A German family-owned enterprise, HERMLE sets the technological benchmark for high-performance 5-axis machining centers. It is the ultimate choice for top-tier users who require extreme precision, optimal dynamic performance, and exceptional thermal stability.

HERMLE holds an unparalleled reputation in mold making and aerospace, making it a preferred solution for machining complex molds and challenging aerospace components from materials like titanium and Inconel. Its slogan, “Performance ist unsere Natur” (Performance is our nature), resonates deeply with its users.

Representative Models: C 250, C 400

| Brand | Core Strengths | Key Applications |

| DMG MORI | Largest scale, broadest portfolio, innovative digital solutions | Mold making, aerospace, general precision machining |

| GROB | Unmatched efficiency and reliability for mass production | Automotive powertrains, new energy systems |

| HERMLE | Ultimate precision, rigidity, and thermal stability | High-precision molds, aerospace superalloys |

Other notable German machine tool brands include Index-Werke, Emag, Trumpf, and Chiron.

7.2. Top 3 American 5-Axis CNC Machine Brands

TOP 1: Haas Automation

Haas Automation has significantly reduced the cost and price of 5-axis technology through standardized production, vertical integration, and direct sales models, making 5-axis machining more accessible. They offer fully equipped, reliable, and durable 5-axis machining centers (such as the UMC series universal machining centers) at prices far lower than their European and Japanese competitors.

Haas Automation has significantly reduced the cost and price of 5-axis technology through standardized production, vertical integration, and direct sales models, making 5-axis machining more accessible. They offer fully equipped, reliable, and durable 5-axis machining centers (such as the UMC series universal machining centers) at prices far lower than their European and Japanese competitors.

Representative Models: UMC-750, UMC-1000, UMC-1500 series universal machining centers.

TOP 2: Hardinge (Bridgeport)

Bridgeport’s 5-axis machines are widely used in precision machining fields such as mold manufacturing, aerospace, and medical applications, particularly for high-precision processing of medium and small parts.

Representative Models: Bridgeport GX 1000, Bridgeport VMC 800

TOP 3: Fadal Engineering

Fadal is a traditional American machine tool manufacturer known for offering cost-effective CNC machines, with high market recognition, especially in the 5-axis machining sector.

Representative Models: VMC 4020, VMC 6030

7.3. Top 3 Japanese 5-Axis CNC Machine Brands

TOP 1: Mazak (Yamazaki Mazak)

Mazak covers nearly all forms of 5-axis machines, including vertical machining centers, 5-axis turning-milling hybrid centers, and 5-axis gantry machining centers. Its INTEGREX i-series 5-axis turning-milling hybrid center is a global industry benchmark.

Mazak covers nearly all forms of 5-axis machines, including vertical machining centers, 5-axis turning-milling hybrid centers, and 5-axis gantry machining centers. Its INTEGREX i-series 5-axis turning-milling hybrid center is a global industry benchmark.

TOP 2: Makino

Makino 5 axis CNC machines are the industry leader when it comes to processing large, complex, and high-hardness mold steels, excelling in precision, surface finish, and efficiency. Their D500 5-axis machining center is a classic in the mold industry.

Makino 5 axis CNC machines are the industry leader when it comes to processing large, complex, and high-hardness mold steels, excelling in precision, surface finish, and efficiency. Their D500 5-axis machining center is a classic in the mold industry.

TOP 3: Okuma

Okuma machines are known for their robust structure and are particularly skilled at handling large parts and heavy cutting operations. They are highly advantageous in the energy, shipbuilding, and large equipment manufacturing sectors.

Okuma machines are known for their robust structure and are particularly skilled at handling large parts and heavy cutting operations. They are highly advantageous in the energy, shipbuilding, and large equipment manufacturing sectors.

Other well-known Japanese 5-axis machine brands include Sodick, Brother, Yasda, and Mitsubishi.

7.4. Top 3 Chinese 5-Axis CNC Machine Brands

Top 1: Beijing Jingdiao

Beijing Jingdiao is renowned for its high-precision 5-axis machines, which are easy to operate and have a leading edge in the precision mold manufacturing and micro-part processing sectors. It is especially suitable for small-batch production and parts that require high precision. Representative models include the JDS-510 and JDS-6030.

Beijing Jingdiao is renowned for its high-precision 5-axis machines, which are easy to operate and have a leading edge in the precision mold manufacturing and micro-part processing sectors. It is especially suitable for small-batch production and parts that require high precision. Representative models include the JDS-510 and JDS-6030.

Top 2: Huazhong CNC

Huazhong CNC is one of China’s leading manufacturers of CNC machine tools, focusing on the development and manufacturing of high-end CNC systems and 5-axis machines. Their 5-axis machines are widely used in industries such as aerospace, automotive, mold-making, and precision machinery. Representative models include the VMP Series and VM Series.

Huazhong CNC is one of China’s leading manufacturers of CNC machine tools, focusing on the development and manufacturing of high-end CNC systems and 5-axis machines. Their 5-axis machines are widely used in industries such as aerospace, automotive, mold-making, and precision machinery. Representative models include the VMP Series and VM Series.

Top 3: Dalian Machine Tool Group Dalian Machine Tool Group is a leading enterprise in the Chinese machine tool industry, dedicated to the research and production of high-precision CNC machine tools. Their 5-axis machining centers are widely used in industries such as aerospace, automotive, and energy. Representative models include the DLW Series and DLW 1600.

Dalian Machine Tool Group is a leading enterprise in the Chinese machine tool industry, dedicated to the research and production of high-precision CNC machine tools. Their 5-axis machining centers are widely used in industries such as aerospace, automotive, and energy. Representative models include the DLW Series and DLW 1600.

We can see most of the famous 5-axis brands are from Germany and Japan.Based on performance, technology, precision, and market influence, below are the top 5 brands ranked in the world:

DMG Mori (Germany/Japan)

GROB (Germany)

HERMLE (Germany)

MAZAK (Japan)

Makino (Japan).

8. 5-Axis CNC Machined Part Inspection

The inspection of 5-axis machined parts is a critical yet highly challenging aspect of high-end manufacturing, often matching the complexity of the 5-axis machining process itself.

The main goal is to check that every detail — the shapes, the curves, the placement of features — lines up exactly with the original design intent in the CAD model.

CNC workshops equipped with 5-axis machines, especially those with continuous 5-axis machining, typically invest in Coordinate Measuring Machines (CMMs). Many of the factories we’ve visited operate multiple CMMs to ensure precision and efficiency in quality control.

Additional inspection tools include Laser scanners, Optical 3D scanners and Electronic comparators.

9. Conclusion

Through this blog, we have explored the fundamentals of 5-axis machining, its classifications, leading global brands in 5-axis technology, and the essential equipment used for inspecting 5-axis parts.

In China, 5-axis machining is becoming increasingly widespread. Larger manufacturers invest in continuous 5-axis systems, while many smaller factories enhance their capabilities by adding rotary tables to achieve 3+2 axis machining.

For insights on selecting a high-quality 5-axis machining service provider in China, we invite you to read our blog: TOP 5 China 5-Axis CNC Machining Service Suppliers.

10. FAQ

10.1. When converting a 3-axis machine to a 5-axis system, is it typically a 3+2 configuration? Can it be upgraded to a continuous 5-axis system?

The conversion of 3-axis machines to 5-axis is predominantly achieved through a 3+2 configuration rather than a continuous (simultaneous) 5-axis system.

This is due to significant structural limitations, simpler control system requirements, and the lower overall cost and complexity of 3+2 retrofits.

While a continuous 5-axis conversion is theoretically possible, it is often impractical and prohibitively expensive, necessitating extensive modifications to the machine’s structure, high-precision drive systems, and advanced CNC controllers.

For most small to medium-sized CNC machining shops, a 3+2 upgrade offers a cost-effective solution for machining complex parts by repositioning the workpiece.

However, investing in a continuous 5-axis system is only justifiable for specialized applications demanding uncompromising precision for complex contours, where the high cost is warranted by specific production needs.

10.2. Is head-head type always continuous 5-axis machine?

Yes. Head-head type 5-axis machines are typically designed as continuous (simultaneous) 5-axis systems.

These configurations allow the spindle to rotate and tilt dynamically while coordinating with the machine’s linear and rotary axes in real-time.

This capability enables complex, high-precision machining of intricate geometries in a single setup, making them ideal for industries such as aerospace, automotive, and medical manufacturing.

Unlike simpler 3+2 systems, these machines offer full five-axis synchronization, providing greater flexibility, accuracy, and efficiency for cutting sophisticated contours and surfaces.

10.3. Can table-table 5-axis machines be both continuous 5-axis and 3+2?

Yes, table-table 5-axis machines can be configured as either continuous 5-axis or 3+2-axis, depending on the specific rotary table design, the use of rotational axes, and the control system configuration.

Continuous 5-Axis: The table or trunnion dynamically coordinates with the spindle and other axes during machining, allowing real-time adjustments of the tool and workpiece in multiple directions.

3+2-Axis: The rotation of the table or trunnion is static; after the workpiece angle is set, the machine performs only standard 3-axis machining.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

What is 5-axis Machining? A Complete Guide.

5-Axis CNC machining is a manufacturing process that uses computer numerical control systems to operate 5-axis CNC machines capable of moving a cutting tool or a workpiece along five distinct axes simultaneously.

Which Country is Best for CNC Machining?

China is the best country for CNC machining service considering cost, precision, logistic and other factors. Statistical data suggests that China emerges as the premier destination for CNC machining.

Top 5 Prototype Manufacturing China

Selecting the right prototype manufacturing supplier in China is a critical decision that can significantly impact the success of your product development project.

CNC Machining Tolerances Guide

Machining tolerances stand for the precision of manufacturing processes and products. The lower the values of machining tolerances are, the higher the accuracy level would be.