- Capabilities

-

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

CNC Turning Services

Reliable high quality on-demand CNC turning services for rapid prototypes and low volume parts.

- Tight tolerance up to 0.005 mm

- Milled parts as fast as 1 day

- Engineer support with DFM report

All your designs are secure and confidential

What is CNC turning services?

CNC turning services produce parts by placing a blank on a rotating chuck and eliminating products using fixed cutting devices. This innovation is excellent for getting rid of symmetry along their facility axis. Turned parts are typically produced faster (and at a reduced price) than CNC-milled parts.

ECOREPRAP CNC turning process produces custom prototypes and end-use production parts as rapidly as one day. We use a CNC turret with online tooling so functions like axial and radial holes, flats, grooves, and ports can be machined.

With the CNC turning services provided by us, you can make the following parts:

functional prototypes and end-use parts

parts with cylindrical features

parts with axial and radial holes, flats, grooves, and ports

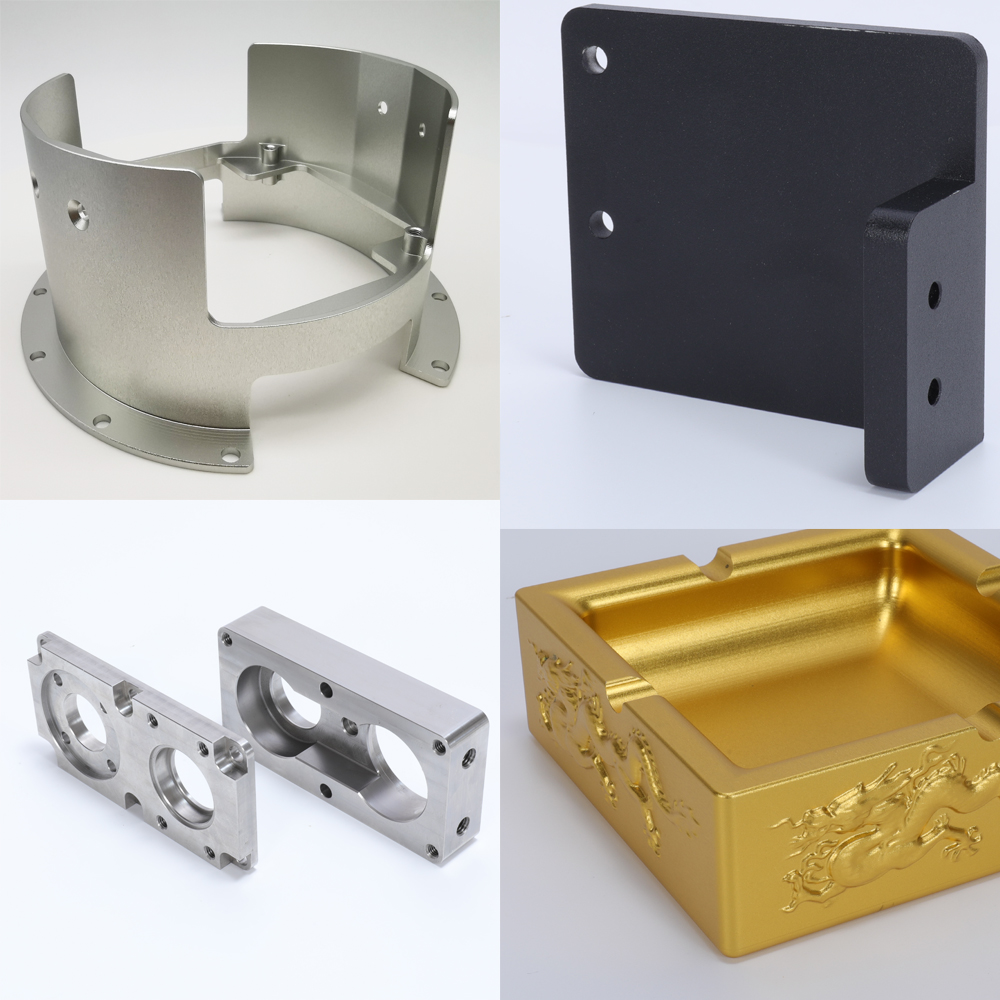

CNC Turning Parts Gallery

CNC Turning Materials

CNC Turning Metals

There are diverse metals suitable for the CNC turning process, for example, aluminum, stainless steel, tool steel and others. CNC milled parts are suitable for prototypes and customized end-use parts.

CNC Turning Plastics

At ECOREPRAP, we offer more than 10 types of CNC turning plastics, such as ABS, Acrylic, POM, PEI, PEEK and others. Turned plastics have a better surface roughness than milled parts.

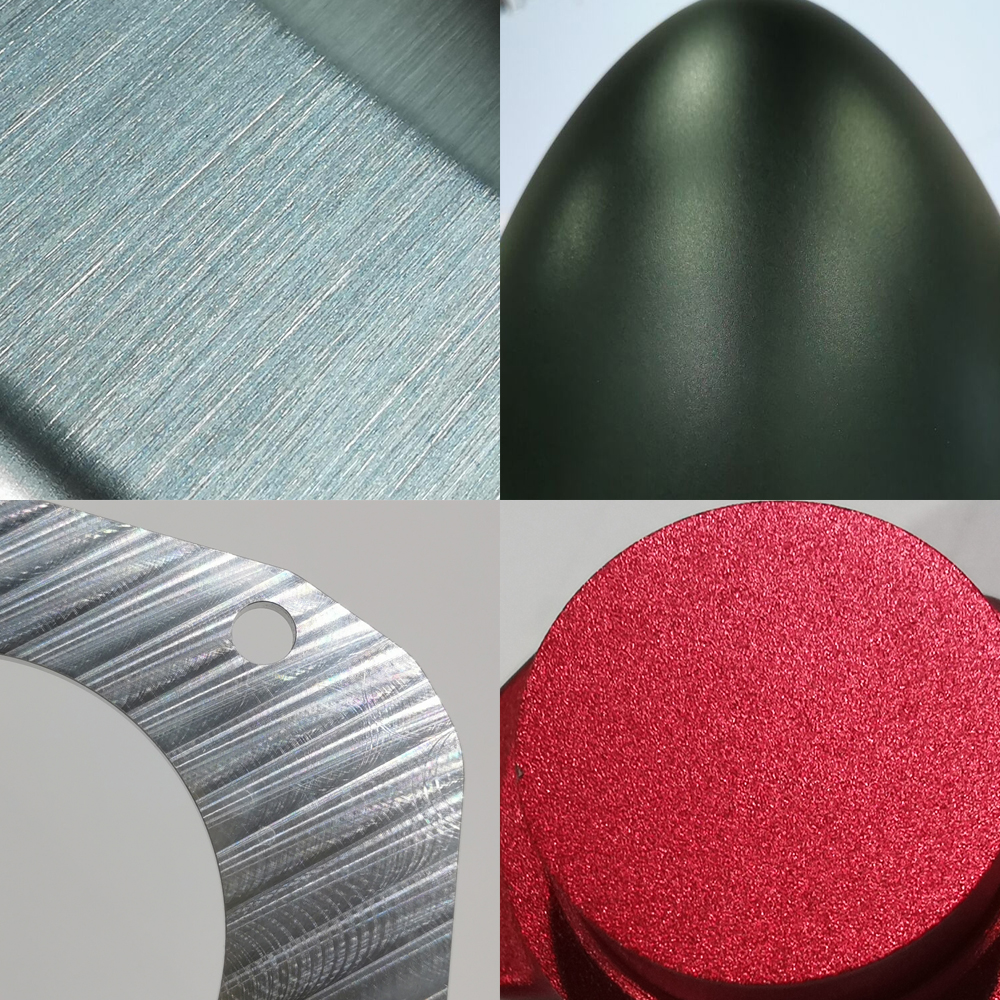

CNC Turning Surface Finishes

The surface finish of CNC-turned parts is usually higher than that of CNC-milled parts, with typical smoothness reaching Ra1.6. Take UHMWPE, for example; the surface finish achieved through CNC turning is typically smoother than CNC milling for the same material.

Many surface treatments are available to enhance your component’s performance by choosing top-notch surface finishes that improve roughness, hardness, chemical resistance, and aesthetics.

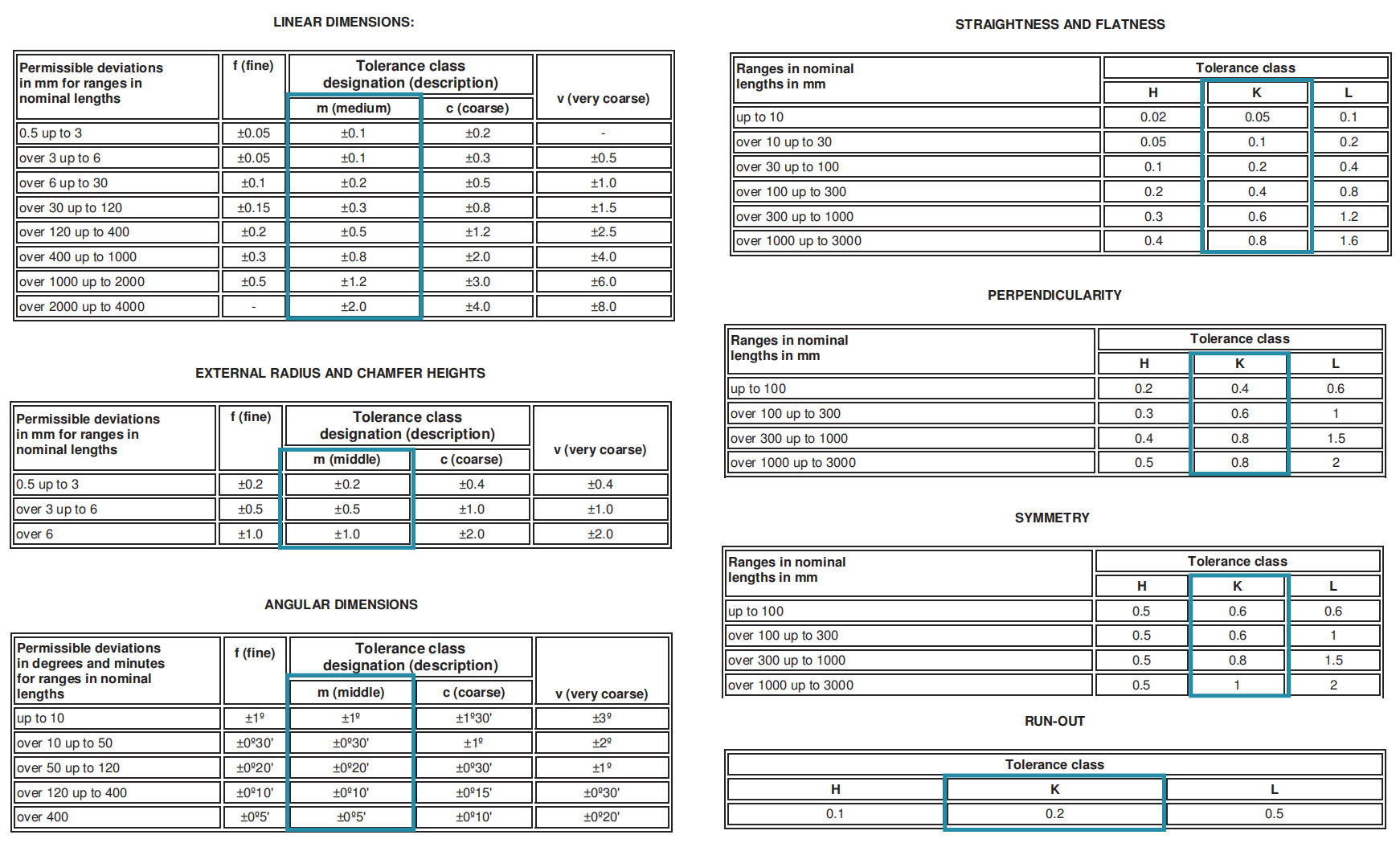

Precision CNC Turning Tolerances

We strictly produce parts according to the tolerances indicated on the customer’s 2D drawings, tight tolerance can be up to 0.005mm. Without specific instructions, at ECOREPRAP, we follow the ISO 2768-MK tolerance standards both for turning metals and plastics.

CNC Turning Design Guidelines

Based on our practices, we summarize ECOREPRAP CNC machining design guides, which aim to help designers optimize the CNC parts design and ensure the final parts are manufacturable, cost-effective, and meet the required specifications.

Feature

Recommended Size

Feasible Size

Min. feature size

Ø 2.5 mm

Ø 0.50 mm

Internal edges

R 8 mm

R 0.25 mm

Minimum wall

thickness

0.8 mm (for metals)

1.5 mm (for plastics)

0.5 mm (for metals)

1.0 mm (for plastics)

Holes

Diameter: standard

drill bit sizes

Depth: 4 x diameter

Diameter: Ø 0.5

Depth: 10 x diameter

Threads

Size: M6 or larger

Length: 3 x diameter

Size: M2

CNC Turning FAQs

The CNC turning process is mostly ideal for cylindrical-shaped raw materials. However, several manufacturers also use it for hexagonal and square-shaped workpieces. It is a popular method for making machine parts for microfluidic tools, signage components, surgical instruments, automotive frames, and aerospace parts.

Yes, ECOREPRAP CNC turning services include plastic parts manufacturing like acrylic, POM, PEEK and others. We can produce small or large-batch prototypes and parts from various engineering-grade plastics. Please choose from our extensive range of plastic materials and upload your design file to get custom plastic components.

The major difference between CNC milling and CNC lathe is in their machining process. CNC milling involves rotating the cutting tools against a stationary bar stock or workpiece. In contrast, a CNC lather works by rotating the bar stock or workpiece against a stationary tool. CNC milling is more suitable for machining irregular and flat surfaces, while CNC lathes work best for cylindrical or conical parts.

Typically, we recommend a minimum wall thickness of 0.5mm for metals and 1mm for plastics. However, these values largely depend on the size of the part; therefore the larger the part size, the higher the recommended minimum wall thickness should be. Please keep in mind that this does not imply that wall thicknesses with lesser values are unachievable. These recommendations are simply thresholds to limit the risk of warpage.

If a specific fillet radius is required, please specify. If not, the fillet radii that allow for easy machining will be added based on the machinist’s discretion. For a general idea, internal vertical edge radii could be >1/3*Depth and internal horizontal edges may be left sharp or have a 0.5mm to 1mm radius.

We can turn parts with diameters ranging from 0.5mm to 65mm for stock bars. Our turning capabilities can reach up to 3000 mm for billets.

Rough turning removes as much material as possible without a focus on accuracy and surface finish, getting the workpiece close to the desired shape. Finish turning “finishes” the process, producing the desired smoothness and accuracy.

CNC turning is the process of cutting along the axis of the workpiece on a lathe. The cutting tool typically contacts the workpieces at their tip, rotating on the lathes and machining along the axis of the workpieces.

1. The tool rotates along the workpiece’s axis for CNC turning, which can get more uniform cutting forces and vibrations. The vibration impact and excessive cutting forces will be reduced. In contrast, CNC milling always has complex lateral cutting on the workpiece surface. It will increase the instability of cutting forces and decrease surface quality.

2. Turning along the axis minimizes changes in the cutting tool angles, ensuring more excellent contact between the cutting tool and the workpieces.

3. Turning along the axis helps reduce surface irregularities and cutting edge wear.

CNC lathes are most often only 2 axis machines with one spindle. They also don’t have high production capabilities and typically don’t have a protective enclosure around the machine. CNC turning centers are more advanced versions of CNC lathes with up to 5 axes and more versatility in cutting ability. They also offer the ability to produce higher volumes and usually integrate milling, drilling, and other capabilities.

CNC turning service near me gives a safe sense of customers for financial payment. For Americans and Europe, the cost can be pretty expensive. Using online CNC turning services from China will save a lot of money.

Good China CNC manufacturers can provide high-precision machined parts, faster lead time, timely English communication, and quite a reasonable price.