Home > CNC Machining Materials > Plastics > PPS

CNC Machining Materials

PPS CNC Machining

PPS, otherwise known as Polyphenylene Sulfide, is a unique type of synthetic material prized for retaining its properties under intense temperatures and pressures as well as when assailed by powerful solvents. Such adaptability renders it ideal for diverse industrial implementations. Within automotive manufacturing, for example, PPS components are poised to endure the searing heat emanating from engines and prolonged contact with corrosive fluids like fuel and lubricants.

Meanwhile, in electronics fabrication, PPS selection stems from how it remains stable and dependable even when permeated by warmth or chemicals throughout production cycles.

Aerospace also leans heavily on PPS due to how it can sustain extremes associated with atmospheric passage.

Likewise, within chemical processing, PPS usage involves equipment and containers confronting hazardous materials.

This resilient, enduring, and multi-faceted plastic constitutes a cornerstone material for numerous domains where reliability and output are paramount.

All uploads are secure and confidential

PPS CNC Machining

PPS is a kind of high-performance engineering plastic with excellent mechanical properties, and chemical resistance as well as heat resistance.

Ruicheng has rich experiece on the processing of PPS. All the PPS can be CNC machined to perfect parts for applications in the aerospace, automotive, electronics, and medical device industries.

Advantages of PPS CNC machining

1.High Precision

CNC machined PPS parts have high precision. The size of the parts is very stable, does not change with time.

The surface of the part is free of defects and meets strict dimensional tolerance requirements.

2.Complex geometries

PPS parts have 5-axis CNC processed geometric shape of complexity and arbitrary shape, which is convenient for the integrated processing of complex parts.

3.Efficient production

CNC machine tools are mechatronic machining equipment. The processing of parts is done automatically.

The efficiency of the machine tool is very high. It can process multiple patterns at one time and improve production efficiency and reduce production time.

4.Material properties

PPS material has excellent performance, which can adapt to high temperature, humidity, and strong corrosion, making it an ideal material for an exacting application.

Overall, CNC machined PPS parts are undoubtedly the ideal equipment for these applications.

Applications of CNC Machined PPS

1.Aerospace

Manufacturing lightweight, high-strength structural components that withstand high temperatures and stress environments.

2.Automotive Industry

Producing engine parts, electronic control units, and other critical components, offering excellent heat and chemical resistance.

3.Electronics

Manufacturing high-precision electronic components and insulation materials, ensuring stable electrical performance.

4.Medical Devices

Machining high-precision medical equipment parts, meeting stringent hygiene and safety standards.

PPS CNC machining can achieve high precision and efficiency. Opting for PPS CNC machining ensures high-quality products and meets various applications’ diverse and demanding needs.

PPS Properties

| Tensile Strength | Elongation at Break | Hardness | Density | Application | ||

| PPS | 13,000 PSI | 0.04 | Rockwell R125 | 1.30g/cm3 | Automotive parts, Appliances, Electronics, Medical devices | Learn More |

PPS CNC Machining Surface Finishes

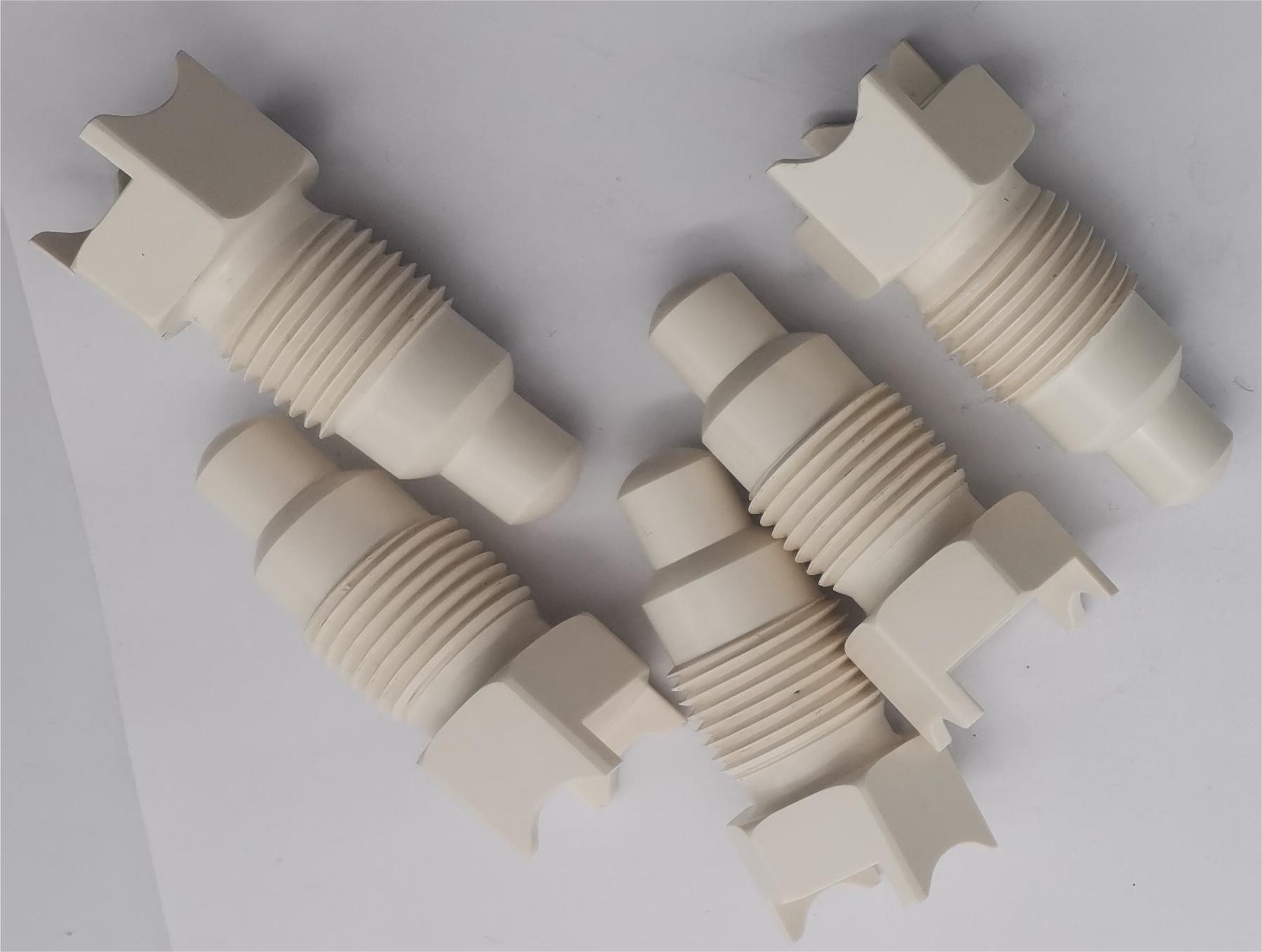

PPS CNC Machining Gallery

Cost-saving Design Tips

While CNC machining can certainly save money with the right approach, designing complex geometries takes more effort and eats into savings. Simple, straightforward shapes expedite production and reduce costs.

Furthermore, uniform stock thickness maintains stability during machining without demanding extra steps to keep dimensions precise.

Deep cuts and awkward contours often require custom tooling or multiple cutting passes, lengthening processing and inflating expenses.

Proper fixation is paramount as well, since secure fixturing is crucial for machining accuracy and efficiency.

Parts that accommodate simple, effective clamping spend less time in production. What’s more, consulting the CNC operator upfront helps optimize the design for minimal cost.

Shrewd geometries and material thicknesses facilitate faster machining at lower cost. Keeping designs simple, using common stock sizes and considering fixation and machinability from the design phase helps ensure production savings.

With a pragmatic strategy, CNC can yield quality parts very affordably.

FAQs

Polyphenylene sulfide (PPS) is a semicrystalline, high-temperature engineering thermoplastic. With a highly stable molecular structure, it has the best performance in harsh chemicals. PPS exhibits a number of desirable properties, including resistance to heat, acids, alkalines, mildew, bleaches, aging, sunlight, and abrasion.

PPS is a fantastic material for machining. Its low shrinkage and stable dimensional properties make it easy to machine to incredibly tight, precise tolerances. Besides being more lightweight, plastics are also more cost-effective than raw metal materials used in part fabrication, in part due to the ability to be produced in faster cycles than metals.