Surface Finishes

Media Tumbled Services

Remove sharp edges,burrs and machine marks on machined parts in batches.

Media Tumbling

Tumbling is a finishing procedure that is used to clean, deburr, and a little smooth smaller parts. Tumbling uses a horizontal drum where components are placed, in addition to the media, such as sand or ceramic chips. The drum turns slowly, triggering the media to move repetitively over the components, damaging any type of sharp edges and lightly smoothing the surface area. Tumbling is rather inexpensive because of the percentage of manual work included to run the procedure.

| Applicable Materials | Media | Cosmetic Availability | Visual Appearance |

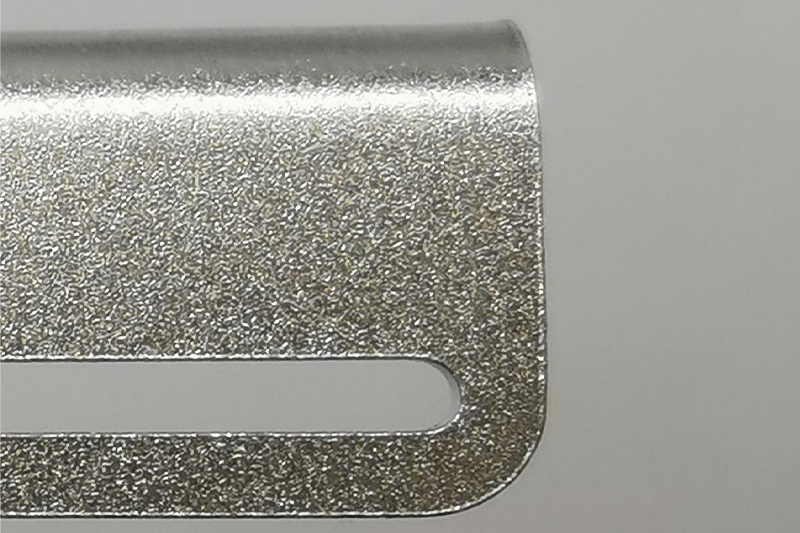

| Aluminum, Steel | Ceramic, Magnetic Rod | On request | Slightly rounded edges, smooth, slightly matte finish, does not hide all machine marks |

Media Tumbling Parts

Media Tumbling Process

Tumbling is a completing process that is made use of to clean, deburr, and somewhat smooth smaller components. Tumbling uses a straight drum where components are put, in addition to the media, such as sand or ceramic chips.

Media Tumbling Design Considerations

To request media tumbling services, kindly note:

- Because parts cannot be masked prior to tumbling,consider adding functions such as strings and engravings hereafter procedure.

- Tumbling is a rough process, so parts with thin features are not ideal for this finishing option.

FAQs

Media tumbling is a surface finishing process that uses abrasive media and a tumbling action to improve the texture and appearance of machined parts.

Media tumbling enhances part appearance, smooths surfaces, removes burrs, and can create a matte or polished finish.

Media tumbling is suitable for various materials, including metals, plastics, and ceramics.

There are two common types of media tumbling processes in CNC machining, magnetic tumbling and vibratory tumbling.

Magnetic Tumbling: Magnetic tumbling typically uses stainless steel pins or small abrasive particles mixed with water and a compound. It is well-suited for materials like stainless steel, aluminum, and other metals.

Vibratory Tumbling: Vibratory tumbling can use a variety of abrasive media, including ceramic, plastic, or organic materials like walnut shells or corn cob. The choice of media depends on the material being processed. Ceramic media is often used for metals, while organic media is gentler and suitable for plastics or delicate materials.