- Capabilities

-

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

MJF 3D Printing Services

High quality Nylon functional prototyping and production at scale using Multi Jet Fusion (MJF) 3d printing as fast as 3 days.

All your designs are secure and confidential

What is Multi Jet Fusion?

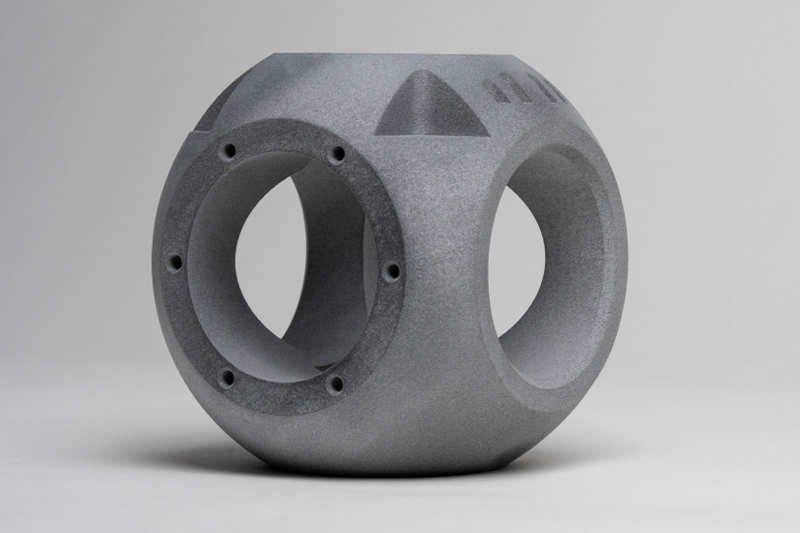

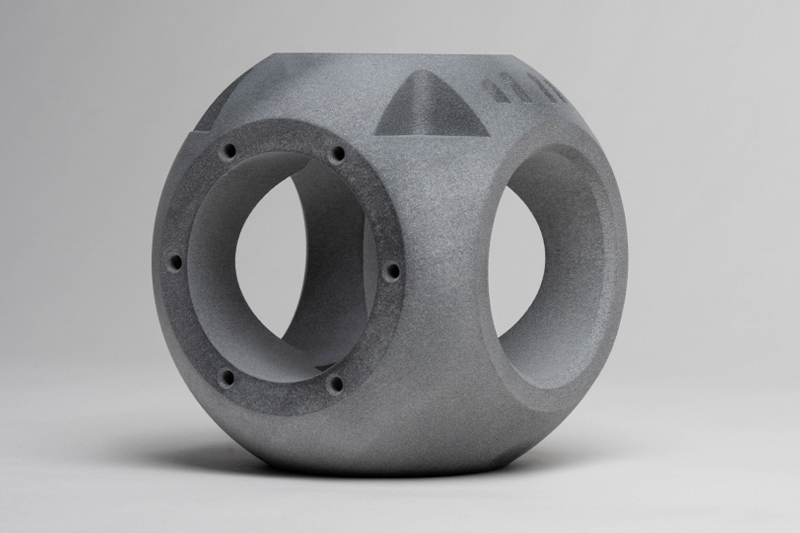

Multi Jet Fusion (MJF) stands as a cutting-edge 3D printing method, renowned for its swift production of precise, intricate parts from powdered thermoplastics. With MJF, you gain access to components boasting exceptional tensile strength and fine feature detailing, making them a prime choice for intricate industrial applications. Originating from HP, this relatively recent 3D printing innovation excels in crafting functional prototypes and production parts characterized by uniform mechanical properties, rendering it indispensable for tasks demanding intricate geometries and impressive cosmetic and functional attributes.

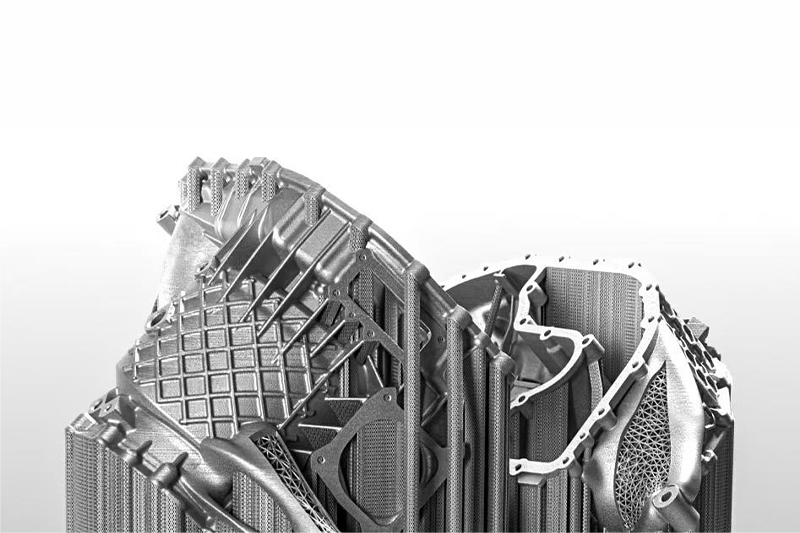

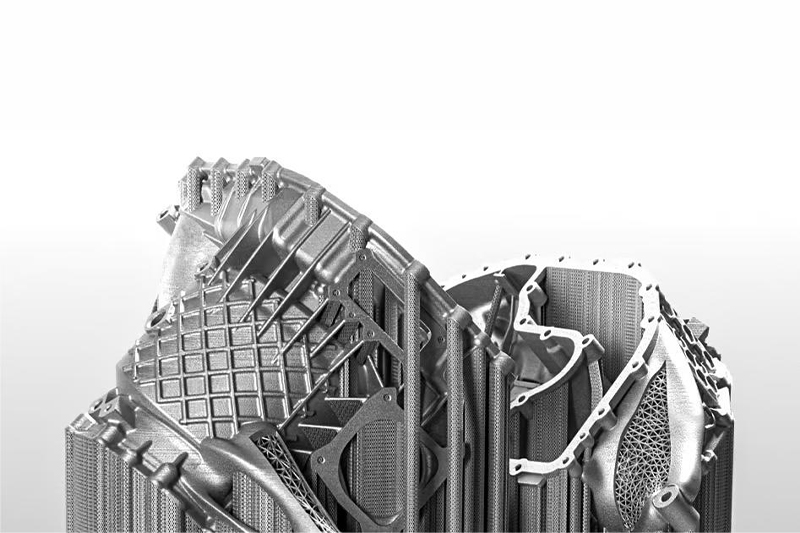

Gallery

MJF 3D Printing Materials

HP PA 12 (Nylon 12)

Gray, dyed black. Functional prototypes, complex assemblies, watertight applications.

Glass-filled HP PA 12

Gray.Enclosures, housings, cases, fixtures, structural parts, tooling.

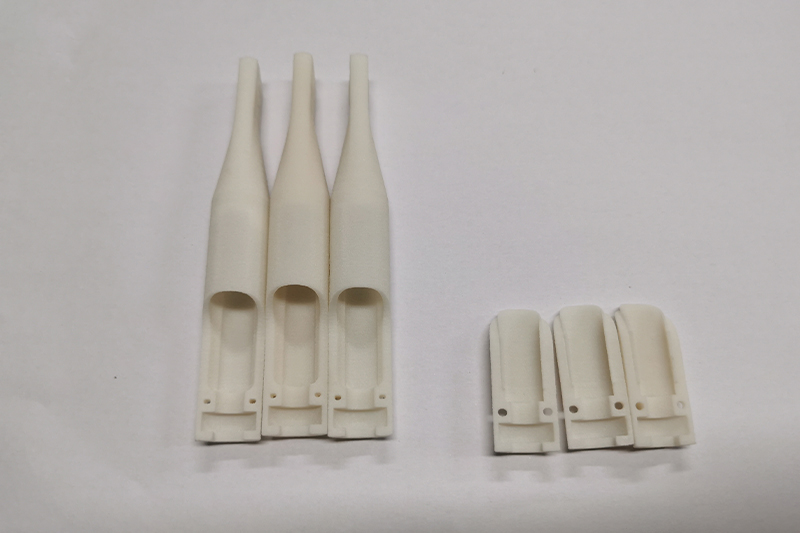

HP PA 11 (Nylon 11)

Prosthetic limbs, insoles, sporting goods, snap, hinge.

MJF 3D Printing Finishes

As Printed

Typically white or stone gray, smooth surface, powder texture, without visible layers.

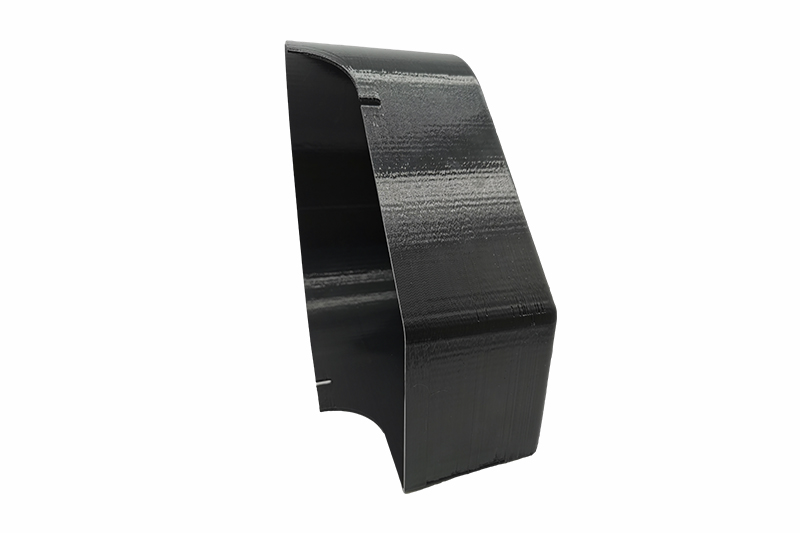

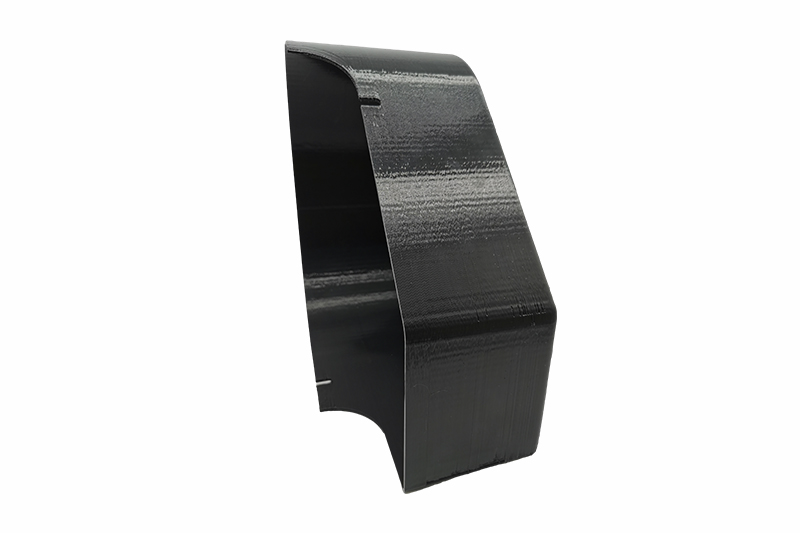

Dyed (black)

Dyed black by immersion in a warm color bath. The color penetration reaches a depth of about 0.5 mm and covers all surfaces.

MJF 3D Printing Tolerance

| Maximum Build Size | Standard Lead Time | Dimensional Accuracy | Layer Thickness | Minimum Feature Size |

| 380 × 284 × 380 mm | From 3 business days | ± 0.3% with a lower limit of ± 0.3 mm | 80μm | 0.5 mm |

MJF 3D Printing Guidelines

The table below summarizes the recommended and technically feasible values for the most common features encountered in MJF 3D printed parts.

Browse MJF 3d printing guidelines

Feature

Recommended Size

Unsupported Walls

1.0 mm

Supported Walls

0.7 mm

Minimum Detail Size

0.25 mm

Minimum Hole Size

1.0 mm

Moving Parts

0.5 mm

Assembly Clearance

0.4mm

Maximum Wall Thickness

20 mm

MJF 3D Printing Advantages And Drawbacks

Advantages

• MJF shines in constructing robust components, boasting remarkable tensile strengths of 48 MPa/6,960 psi in the XY and Z axes, as per the ASTM D638 standard

• MJF proves ideal for shaping parts with diverse mechanical attributes, regardless of their geometry.

• MJF’s advanced automation capabilities significantly diminish the necessity for extensive post-processing.

• MJF delivers swift build speeds, even when handling large quantities of parts, outpacing alternative technologies.

Drawbacks

• Opting for MJF guarantees top-notch parts, though it may come with a higher cost compared to other manufacturing methods.

• MJF offers a limited selection of materials, with the potential for expansion in the future by HP.

MJF 3D Printing Application

Concept Models

The speed and versatility of MJF let product developers create tough and detailed physical snapshots of their designs.

Rapid Prototyping

MJF can be used to create fully-functional prototypes, complete with moving parts, as well as all-in-one assemblies.

Direct Digital Manufacturing

The low price and speed of Multi Jet Fusion make it an ideal way to build large quantities of discrete or customized parts.

3D Printing Technologies Comparision

| Materials | Dimensional accuracy | Strengths | Build Volume | Layer Thickness | Min. Feature Size | |

| FDM | 3 | ± 0.5% with a lower limit on ± 0.5 mm | Low cost, wide range of materials | 500 x 500 x 500 mm | 100-300μm | 2.0 mm |

| SLA | 3 | ± 0.2% with a lower limit of ± 0.127 mm | Smooth surface finish, fine feature details, big print area | 500 x 500 x 500 mm | 50-100μm | 0.2 mm |

| SLS | 2 | ± 0.3% with a lower limit of ± 0.3 mm | Design flexibility, supports not required | 395 x 500 x 395 mm | 100μm | 0.5 mm |

| MJF | 3 | ± 0.3% with a lower limit on ± 0.3 | Design flexibility, supports not required | 380 x 285 x 380 mm | 80μm | 0.5 mm |

| SLM | 5 | ± 0.2% with a lower limit of ± 0.127 mm | Metal parts | 320x320x400mm | 200μm | 1 mm |

3D Printing Technologies

MJF 3D Printing FAQs

MJF was developed by Hewlett Packard (HP) and introduced in 2016, with the claim that it was capable of print speeds up to 10 times faster than other technologies, and could print up to 12,000 voxels per linear inch, per layer. Voxels are the 3D equivalent of pixels on a 2D printer.

Common MJF applications include housing for electrical components, jigs and fixtures for highly specific purposes, and mechanical assemblies or enclosures.