- Capabilities

-

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

Surface Finishes

Chromate Conversion Coating (Alodine) Services

Chromate conversion coating, more commonly known as chem film or by its brand name Alodine, is a type of conversion coating, used on aluminum as a corrosion inhibitor, as a primerfor paint due to increased adherence or to preserve electrical conductivity.

All your designs are secure and confidential

Chromate Conversion Coating (Alodine)

Chromate conversion covering, even more typically known as chem film or by its trademark name Alodine, is a chemical coating that passivates and secures lightweight aluminum from rust. It is additionally utilized as a base layer before priming and painting parts. This safety layer is much thinner than an anodizing layer, and while both are created by immersion of components into a bathroom, Alodine is a straightforward chemical layer and the procedure does not make use of electricity existing.

Alodine is a somewhat much less expensive procedure than anodizing, though it is extra prone to scrapes, wear, and aesthetic damages. Among the most usual shades of the layer is a rainbow-like greenish-gold, and therefore it might furthermore be made use of for aesthetic objectives. Nevertheless, this color originates from hexavalent chromium, which is toxic, so for RoHS compliance needs, there are clear variations of the layer offered as well.

| Surface preparation | Colors | Applicable materials | Cosmetic availability | Visual appearance |

| As machined (Ra 1.6μm) | Clear/ slight yellow tint | Aluminum (7xxx series not recommended) | No | Machining marks are visible |

| Beadblasted | Clear/ slight yellow tint | Aluminum (7xxx series not recommended) | Cosmetic on request | Machining marks are completely removed on “cosmetic” parts but may be visible on “non-cosmetic” parts |

Chromate Conversion Coating (Alodine) Parts

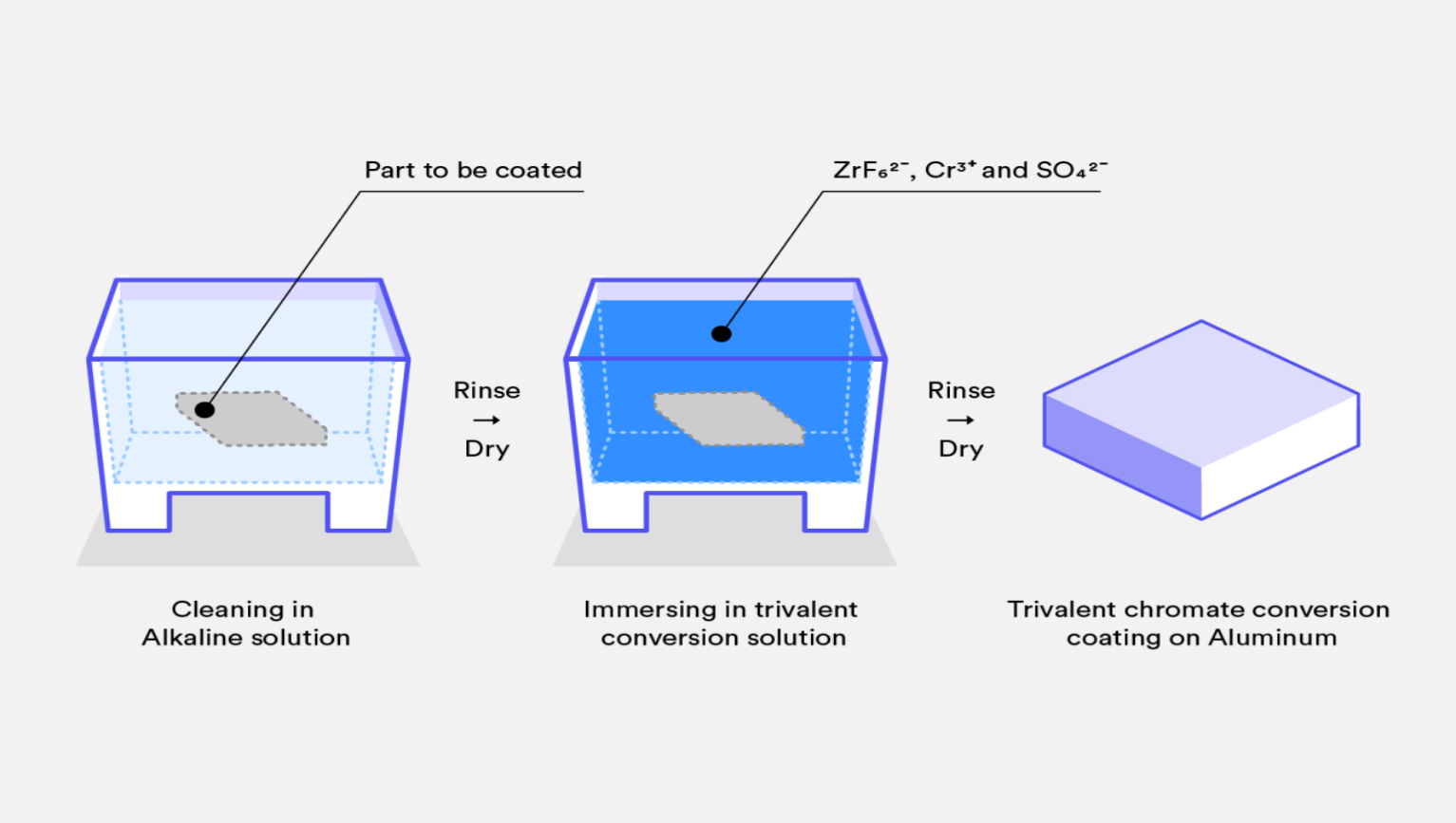

Chromate Conversion Coating (Alodine) Process

Chromate conversion coating entails including chromic acid to steel in a chemical process that results in a slim, protective external layer. This improves a metal’s sturdiness and makes it extra resistant to deterioration.

Below’s how we apply the chromate conversion layer:

1 Parts are cleaned and degreased to remove any type of pollutant

2 Components are rinsed to get rid of any type of deposit of detergent

3 Aluminum parts are submersed in a container having the chemical option

4 Components are eliminated when a film of the wanted thickness layers the surface area

5 Components are after that rinsed again

5 Parts are then rinsed again

Chromate Conversion Coating (Alodine) Design Considerations

- Confirm the metal is compatible with Chromate Conversion Coating. Aluminum, magnesium, zinc, and cadmium are common materials suitable for Alodine treatment.

- Thoroughly clean the metal surface to remove any contaminants, oils, or oxidation. Proper surface preparation is crucial for the effectiveness.

- Select the appropriate type of Alodine based on the material and application requirements.

FAQs

Chromate conversion coatings come in two primary types: hexavalent chromate and trivalent chromate. Hexavalent chromate, while effective, poses environmental and health concerns due to the presence of hexavalent chromium. Trivalent chromate, a more environmentally friendly alternative, is gaining popularity.

Hexavalent chromate coatings typically produce a gold or iridescent yellow color. Trivalent chromate coatings can vary in color, including clear, iridescent, and olive drab. Some versions are specifically designed to be clear or provide a colorless finish.

Chromate conversion coating and Alodine are related processes, but they are not exactly the same. Alodine is a brand name for a specific type of chromate conversion coating. The term “Alodine” is often used colloquially to refer to chromate conversion coatings in general, but it’s important to note that there are various types and brands of chromate conversion coatings, with Alodine being one of them.