Home > CNC Machining Materials > Metals > Mg

CNC Machining Materials

Magnesium CNC Machining

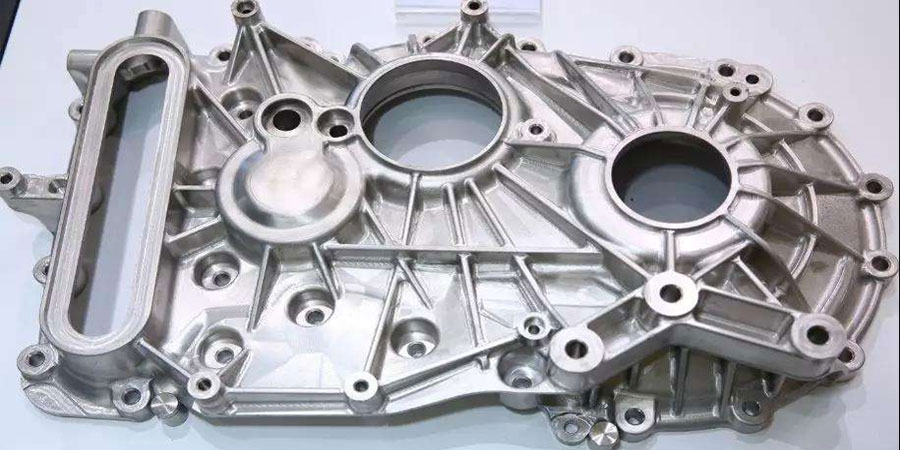

Magnesium, a typical product for die casting, is progressively prominent for CNC machining because it is lightweight and very machinable in regard to feed rates.

All uploads are secure and confidential

Magnesium CNC Machining

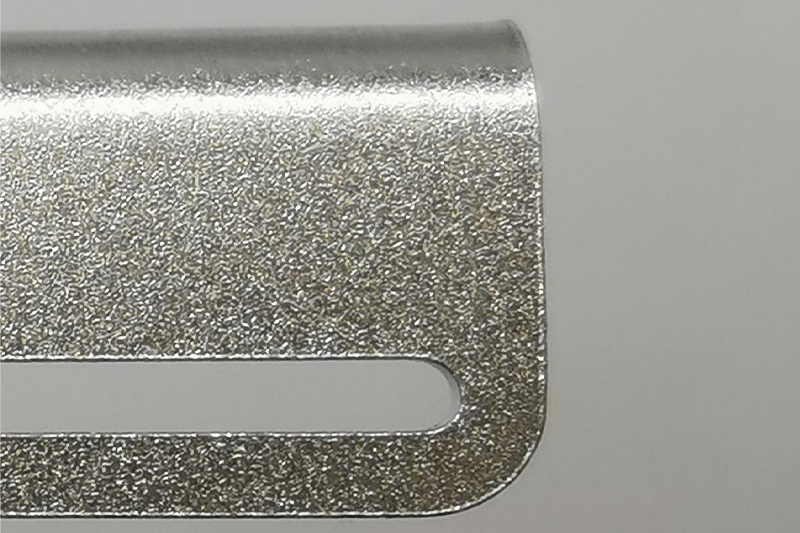

Magnesium, a usual material for die casting, is increasingly popular for CNC machining because it is lightweight and highly machinable regarding feed prices. Machined magnesium also generates exceptional surface area finishes due to shorter chips produced throughout the machining process.

Magnesium CNC Machining is challenging because of its high flammability, mainly when processed into chips or powder.

Therefore, fire prevention measures must be taken during machining, including using the right cutting fluids, keeping the work area clean, and preventing chip accumulation. Selecting the right cutting fluid is crucial.

Generally, water-soluble cutting fluids are recommended to help with cooling and fire prevention. Additionally, good ventilation is helpful to prevent magnesium dust from accumulating in the air.

Chips produced during magnesium machining should be cleaned promptly, stored in fire-resistant containers, and properly disposed of to prevent spontaneous combustion.

Magnesium Subtypes

| Subtypes | Tensile Strength | Elongation at Break | Hardness | Density | |

| AZ31B Magnesium | 29,000 PSI | 15% | Brinell 49 | 1.77 | Learn More |

Magnesium CNC Machining Surface Finishes

Cost-saving Design Tips

To reduce costs, limit the number of part setups, inspection dimensions or tight tolerances, and deep pockets with small radii.

FAQs

AZ31B Magnesium.

Aerospace, automotive, and medical equipment industries frequently use magnesium components.

Yes, magnesium is flammable, and machining should be done with proper safety measures.

Yes, surface treatments like anodizing and chromate conversion coatings can enhance corrosion resistance.

Yes, magnesium’s low density makes it ideal for weight-sensitive applications.

Magnesium can be prone to corrosion and requires specialized machining techniques.

Designers should consider material selection, corrosion resistance, and fire safety when working with magnesium.