- Capabilities

-

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

Home > CNC Machining Materials > Metals > Tool Steel

CNC Machining Materials

Tool Steel CNC Machining

Tool steels are metal alloys with extremely high hardness, stiffness and abrasion resistance. Suitable for producing industrial devices.

All uploads are secure and confidential

Tool Steel CNC Machining

Tool steel is any one of the different carbon and alloy steels that are especially well-suited to be made into tooling, such as cutting devices, dies, hand tools, blades, and others. Tool steel’s viability originates from its unique hardness, resistance to abrasion and deformation, and capability to hold a reducing side at elevated temperature levels.

Consequently, tool steels are matched for usage in shaping other products, such as cutting, machining, stamping, or creating.

A2 Steel: A2 steel is a cold-work tool steel with good cutting performance and toughness. It is used for manufacturing cooling molds, die holders, and extrusion dies.

D2 Steel: D2 steel is a high-carbon, high-chromium cold-work tool steel with excellent hardness, wear resistance, and cutting performance. It is suitable for making cutting tools, stamping dies, and cold-work molds.

O1 Steel: O1 steel is a classic oil-hardening cold-work tool steel with good hardness, wear resistance, and cutting performance. It is suitable for making cutting tools, molds, and die holders.

H13 Steel: H13 steel is a hot-work tool steel with good high-temperature strength and heat resistance. It is used to make hot-work molds, die-casting molds, and extrusion dies.

S7 Steel: S7 steel is a cold-work tool steel with good impact toughness and wear resistance. It is used for making impact dies, die holders, and extrusion dies.

All tool steels mentioned above can be heat treated to improve their hardness and strength.

Tool Steel Subtypes

| Ultimate tensile strength | Yield strength | Young’s modulus (modulus of elasticity) | Elongation at break | Corrosion resistance | Magnetism | Weldability | Application | ||

| Tool Steel A2 | 670 – 710 MPa | 345 – 350 MPa | 190 GPa | 21 % | Poor | Magnetic | Moderate | Cutting & Shearing tools Cold-forming dies Die casting and molding dies | Learn More |

| Tool steel A3 | 700 MPa | 340 MPa | 190 GPa | 21% | Poor | Magnetic | Poor | Cold forging & heading dies Cold forging dies Shear blades Knurling tools | Learn More |

| Tool steel D2 | 758 – 860 MPa | 420 – 470 MPa | 190 GPa | 16% | Poor | Magnetic | Poor | Hot forging tools and dies Hot extrusion tools and dies Cold forming dies | Learn More |

| Tool steel O1 | 640 – 720 MPa | 400 MPa | 190 GPa | 20% | Poor | Magnetic | Poor | Cutting tools Cold-forming dies Shearing tools Die casting and molding dies | Learn More |

| Tool steel S7 | 640 – 670 MPa | 370 – 380 MPa | 190 GPa | 21 – 25 % | Poor | Magnetic | Poor | Cutting tools Hot forging & extrusion tools Cold-forming dies Shearing tools | Learn More |

| Tool steel H13 | 690 MPa | 330 MPa | 190 GPa | 21% | Poor | Magnetic | Poor | Extrusion & pressure dies Forging & stamping dies Hot shear blades | Learn More |

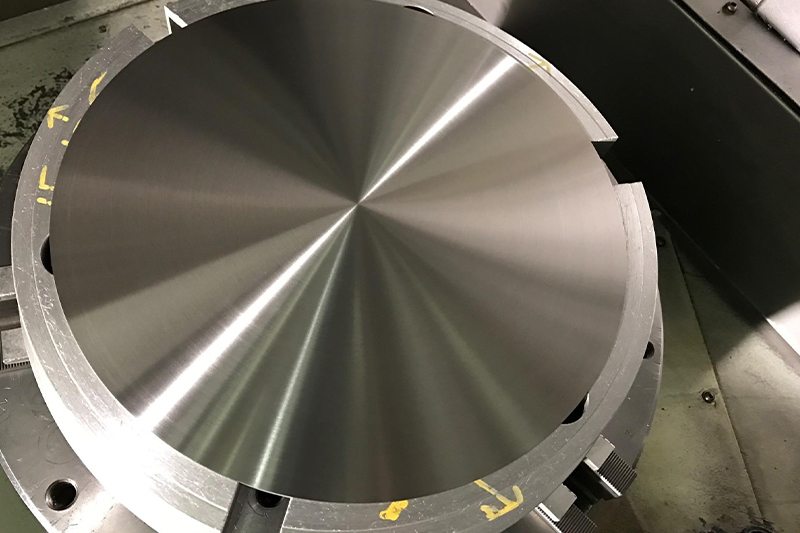

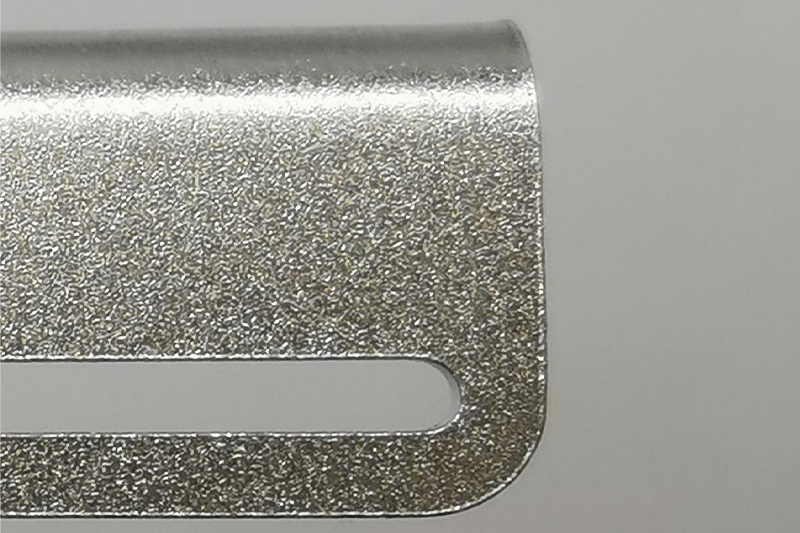

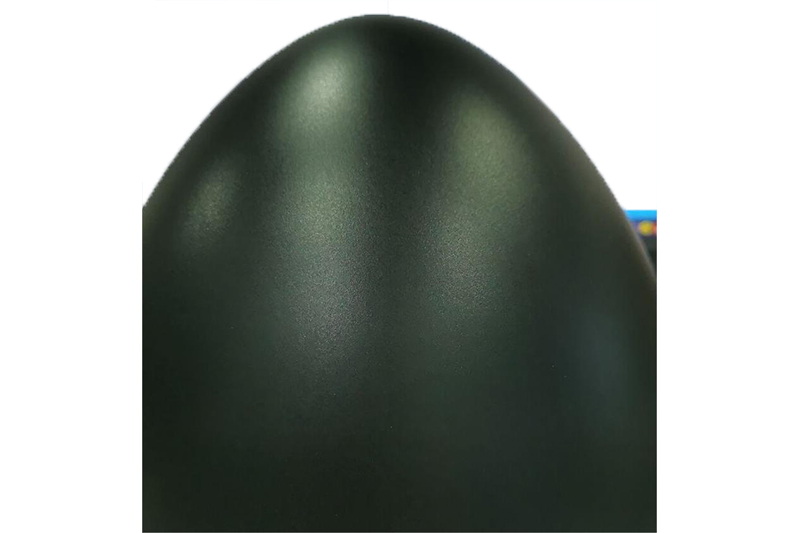

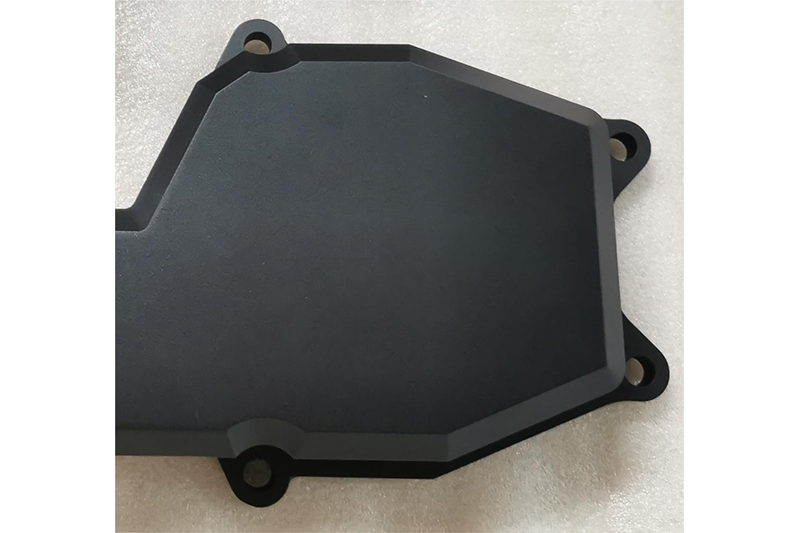

Tool Steel CNC Machining Surface Finishes

Cost-saving Design Tips

To lower costs, restrict the number of part setups, the number of inspection dimensions or tight tolerances, and deep pockets with small radii.

FAQs

There are six tool steels: water-hardening, cold-work, shock-resistant, high-speed, hot-work, and special purpose. The group selection choice depends on cost, working temperature, required surface hardness, strength, shock resistance, and toughness requirements.

The more severe the service condition (higher temperature, abrasiveness, corrosiveness, loading), the higher the alloy content and consequent amount of carbides required for the tool steel.

Tool steels are used for cutting, pressing, extruding, and coining of metals and other materials. Their use in tooling is essential; injection molds for example require tool steels for their resistance to abrasion- an important criterion for mold durability which enables hundreds of thousands of moldings operations over its lifetime.

Yes, heat treatment is often used to optimize the hardness and wear resistance of tool steel components.

A2, D2, O1 and S7 are the common tool steels used for CNC machining.