- Capabilities

-

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

Home > CNC Machining Materials > Metals > Titanium

CNC Machining Materials

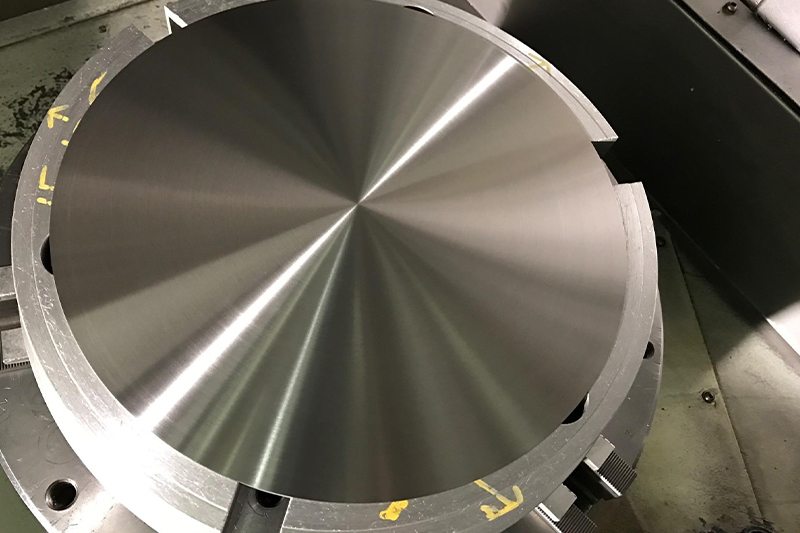

Titanium CNC Machining

Titanium is a metal with excellent strength-to-weight proportion, low thermal development, and high corrosion resistance that is sterilizable and biocompatible.

All uploads are secure and confidential

Titanium CNC Machining

Titanium, whose symbol is Ti on the periodic table, is an often-utilized lightweight metal with a variety of useful properties extending from rust resistance to maintaining strength even under severe temperatures.

In its purest form, titanium contains minute amounts (less than 1%) of iron and oxygen.

Superior alloys of titanium significantly boost overall strength levels.

Offering exceptional corrosion resistance, biocompatibility, and potent strength-to-weight ratios, titanium has proven to be a prized material for resolving innumerable engineering obstacles within the medical, energy, chemical processing, defense, and aerospace sectors.

Whether crafting intricate implants, devising stronger jet engines, or designing cutting-edge prosthetics, titanium’s unique blend of qualities make it a first-choice solution for a wide array of demanding situations.

Titanium Subtypes

| Ultimate tensile strength | Yield strength | Young’s modulus (modulus of elasticity) | Elongation at break | Hardness | Corrosion resistance | Magnetism | Weldability | Application | |||

| Titanium Grade 1 | 310 – 350 MPa | 220 – 240 MPa | 103 – 105 GPa | 28 -32 % | 120 HB | Excellent | Non-magnetic | High | Airframe components Cryogenic vessels Heat exchangers CPl equipment Condenser tubing Pickling baskets | Learn More | |

| Titanium Grade 2 | 420 – 470 MPa | 330 – 360 MPa | 105 – 110 GPa | 23 – 25 % | 80 – 82 HRB | Excellent | Non-magnetic | High | Aerospace Marine industry Medical industry | Learn More | |

| Titanium Grade 5 | 920 – 1000 MPa | 830 – 880 MPa | 113.8 GPa | 9 – 11 % | 334 HB | Very Hight | Non-magnetic | Low | Aerospace | Learn More |

Titanium CNC Machining Surface Finishes

Cost-saving Design Tips

Titanium is a costly material so remember cost considerations during the design phase. Below are some tips that can reduce the expenses of working with it.

1.Material selection

Select the correct material for your application so that its high price doesn’t become excessive. For example, if a lot of material is machined away, Grade 2 titanium may be the better option as it is more machinable. Grade 5, on the other hand, is applicable for high strength at extreme temperatures.

2.Design for manufacturing

Titanium is machined as easily as high-performance steels, but it does make a few unique demands on the machinist. As such, it is critical to follow the specific DFM principles that apply to the metal. Inefficiently designed parts can slow the machining process and thus drive up costs.

FAQs

When CNC machining titanium, low cutting speeds are recommended. Tool tip temperatures can be easily increased by higher cutting speeds, which can compromise tools. Other related factors include sharp tools regularly replaced at the first sign of wear, feed rates high enough to prevent work hardening and the generous use of coolant.

High speed steel (HSS) drills are excellent for Titanium so long as it is sharp, but carbide tipped drills still provide the best results and deep hole drilling. Because titanium is not a great conductor of heat, much of the heat goes into cutting tools, highlighting the need for sharp and well-maintained tools.

Poor Thermal Conductivity – cutting tools end up taking the burden of heat generation.

“Sticky” or “Gummy” Properties – can lead to problems with long “stringy” chips as well as creating built-up edge.

Low Modulus of Elasticity – leads to spring back and chatter while machining.

High Work Hardening Tendency – further increases difficulty of machining.

Titanium has very high strength and a great strength-to-weight ratio. In fact it is only 5% less strong than steel but is 40% lighter making it great for high tech industries such as aerospace, automotive and energy.