- Capabilities

-

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

Home > CNC Machining Materials > Metals > Alumimum

CNC Machining Materials

Aluminum CNC Machining

High machinability and ductility, good strength-to-weight ratio, good electrical conductivity, low density and natural corrosion resistance. Always anodized.

All uploads are secure and confidential

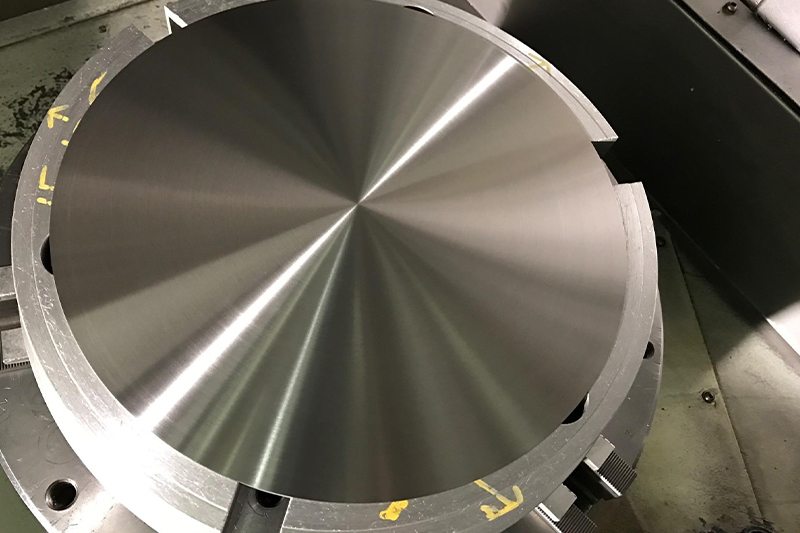

Aluminum CNC Machining

Aluminum is a light-weight alloy with excellent strength-to-weight ratio, high thermal and electric conductivity, low density and natural deterioration resistance. It has superb machinability, welding and electroplating residential or commercial properties as well as great corrosion resistance.

Lightweight aluminum is a material that is easy to cut and machine, and aluminum alloys can be quickly, properly grated, pierced, and machined using CNC machining. After machining, lightweight aluminum has a low threat of contortion or issues and is very easy to polish and color.

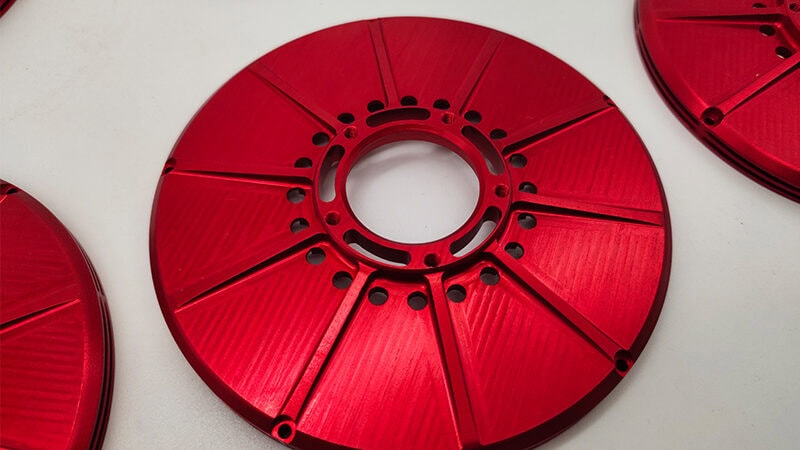

Aluminum is among the most common materials used in the aerospace, medical, auto and motorcycle industries.

Available Aluminum Subtypes For CNC Machining

| Subtype | Ultimate tensile strength | Yield strength | Young’s modulus (modulus of elasticity) | Elongation at break | Corrosion resistance | Magnetism | Weldability | Application | |

| Aluminum 6061-T6 | 260-310 MPa | 240-270 MPa | 68 – 74 GPa | 8-11 % | High | Non-magnetic | High | Automotive industry Marine industry Electrical fittings Couplings & valves | Learn More |

| Aluminum 6063 | 110-210 MPa | 55-130 MPa | 68 – 69 GPa | 8-18 % | High | Non-magnetic | Good | Architectural products Door and windows frames Pipe and tubes for irrigation systems Electrical components | Learn More |

| Aluminum 5052 | 170-210 MPa | 70-120 MPa | 68 – 71 GPa | 7-20 % | Good | Non-magnetic | High | Hydraulic tubes Kitchen appliances Cabinets Small boats Home freezers Aircraft tubes Fencing | Learn More |

| Aluminum 7075-T6 | 520-560 MPa | 460-470 MPa | 69 – 76 GPa | 6-9 % | Moderate | Non-magnetic | Poor | Aircraft and aerospace Marine Transportation | Learn More |

| Aluminum 2024-T351 | 395-470 MPa | 275-310 MPa | 71 – 73.1 GPa | 9-15 % | Poor | Non-magnetic | Good | Aircraft fuselage Commercial & military aircraft Wing tension members Critical Aircraft structures | Learn More |

| Aluminum 2014 | 190-245 MPa | 100-125 MPa | 72 – 73.3 GPa | 11 – 16 % | Poor | Non-magnetic | Fair | Aerospace & Defense industry Truck frames | Learn More |

| Aluminum 7050 | 470-530 MPa | 390-460 MPa | 70 – 80 GPa | 5-12 % | Poor | Non-magnetic | Fair | Fuselage frames Bulkheads Wing skins Aerospace structures Commercial & military aircraft applications | Learn More |

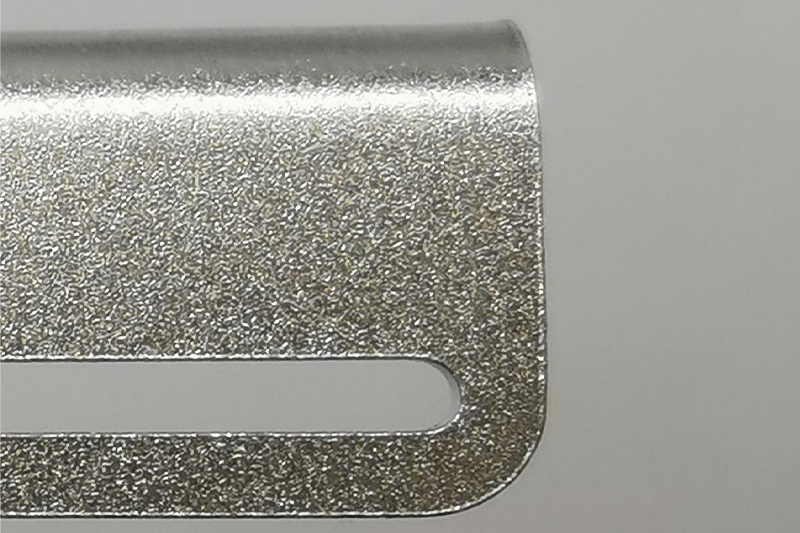

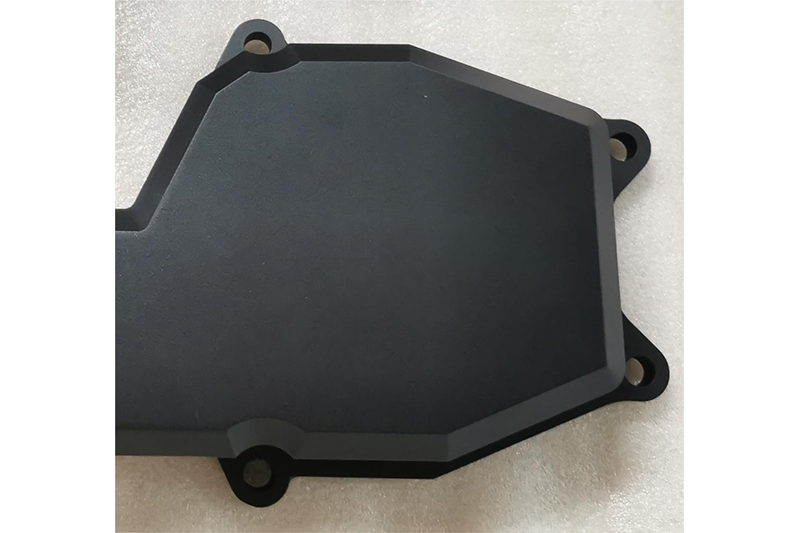

Aluminum CNC Machining Surface Finishes

Cost-saving Design Tips

1.Design for manufacturing

The first tip to save cost when machining an aluminum alloy part is to follow design-for-manufacturing principles to limit difficult-to-machine features, such as setup numbers, inspection dimensions, tight tolerances, and deep pockets with small radii.

2.Choose the right alloy

Using the most innovative and pricey alloy might not be needed if the part is just a prototype. 6061 T6 aluminum is a good choice.

FAQs

Aluminum CNC machining is the process of using computer-controlled machines, such as a CNC mill and a CNC lathe, to shape, cut, and finish aluminum parts.

Aluminum is favored for its lightweight, corrosion resistance, and excellent machinability.

Common alloys include 6061, 7075, 5052, and 6063 for specific applications.

Yes, CNC machining can produce tight tolerances in aluminum parts for precision applications. Tight tolerance is up to 0.005mm.

Options include anodizing, powder coating, painting, and more, depending on the desired appearance and function.

Yes, aluminum’s strength-to-weight ratio makes it a common choice in aerospace and automotive applications.

Aluminum machining is cost-effective for high-volume production due to its efficiency and machinability.

Yes, CNC machining allows for the production of intricate and complex aluminum components.

Yes, with appropriate finishes, aluminum parts can endure challenging conditions.

Aluminum is a versatile choice for prototyping due to its ease of machining and availability.

Yes, when medical-grade or food-safe aluminum is used, it’s suitable for these applications.

Designers should consider material selection, tolerances, and the complexity of the part.

Yes, it’s a quick and cost-effective method for producing prototypes.