- Capabilities

-

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

Surface Finishes

Laser Engrave Services

Get your custom CNC machined parts marked with laser engraving.

All your designs are secure and confidential

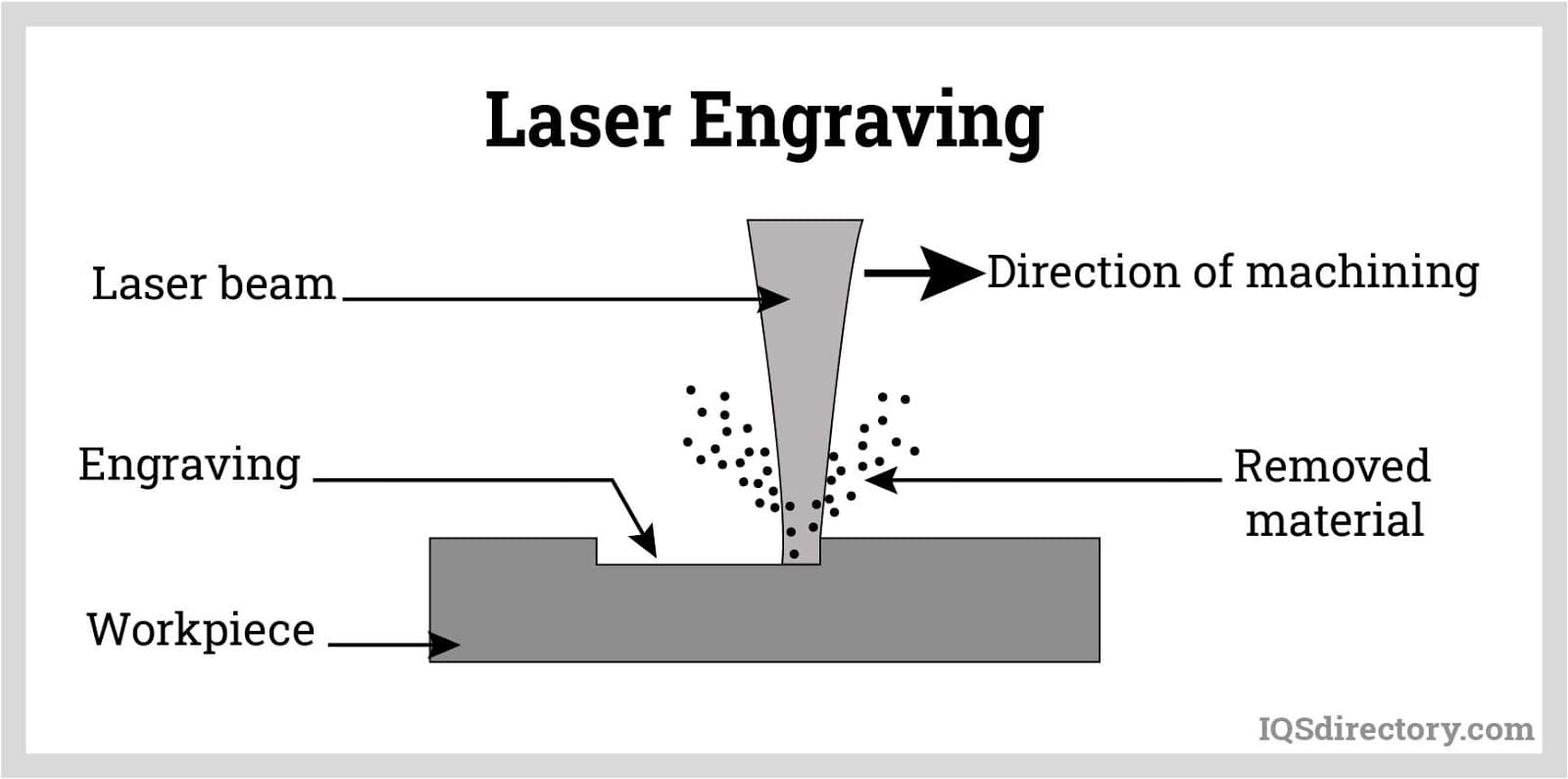

Laser Engraving (Laser Etching)

Laser engraving in CNC machining serves a multifaceted role, contributing to product branding and identification by adding logos and serial numbers, ensuring traceability and fostering brand recognition. Additionally, it facilitates personalization and customization of CNC machined products through the incorporation of personalized text, graphics, or designs, commonly observed in consumer electronics and personalized gifts. Furthermore, laser engraving enhances the aesthetic appeal of CNC machined parts by introducing intricate patterns and artistic designs, particularly applied to decorative elements in automotive parts, jewelry, and consumer goods.

| Applicable Materials | Color Options |

| Metals,Plastics | Natural, White,Black, Gray |

Laser Engraving Part

Laser Engraving Process

1 .Design Preparation: Create or obtain the design or artwork you want to engrave using graphic design or computer-aided design (CAD) software.

2 .Machine Setup: Prepare the laser engraving machine, ensuring it’s correctly calibrated and the laser is focused.

3 .Material Fixturing: Secure the material to be engraved in place on the engraving machine’s worktable or fixture to prevent movement during the process.

4 .Laser Parameters: Configure the laser settings, including power, speed, and frequency, based on the material and design requirements.

5 .Laser Engraving: Start the engraving process, during which the laser beam traces the design onto the material with precision.

6 .Quality Inspection: After engraving, inspect the finished product to ensure it meets the desired quality standards.

7 .Cleaning: Remove any debris or residue generated during the engraving process, leaving the engraved area clean.

8 .Optional Post-Processing: Depending on the material and design, you may choose to perform additional post-processing steps like paint filling, coating, or other enhancements.

Laser Engraving Design Consideration

To request part marking, you will need to provide the following:

- 3D model of the part

- Vector file (typically in AI format) of the font or geometry required for the marking

- Technical drawing (PDF format) indicating the exact location for the marking

FAQs

Laser engraving is a process that uses a high-powered laser to etch or engrave designs, text, or markings onto materials with precision.

Laser engraving is versatile and can be used on materials like metal, wood, acrylic, glass, plastic, and more.

Laser Engraving: This process typically involves using a laser beam to remove material from the surface, creating a deeper and more pronounced mark. Laser engraving is often used for adding logos, text, or designs that need to be highly visible and durable. It creates deeper grooves and can be tactile to the touch. Laser Etching: Laser etching, on the other hand, doesn’t remove material but rather changes the surface’s appearance by altering its texture or color. It creates a shallower mark, and the contrast is achieved by altering the reflective properties of the material. Laser etching is commonly used for marking serial numbers, barcodes, or for aesthetic purposes where a subtle mark is desired.Laser engraving is fast and precise. It provides durable marking that does not wear over time, commonly used for serial numbers.

Laser engraving provides a permanent mark as it physically alters the material’s surface.

Laser engraving provides a permanent mark as it physically alters the material’s surface.

Yes, laser engraving is capable of producing intricate and highly detailed designs with precision.

Laser engraving typically has minimal impact on material dimensions, making it suitable for precision parts.

Laser engraving is ideal for batch production, as it offers consistent quality and rapid marking.

Laser engraving is perfect for fine text, serial numbers, barcodes, and other detailed markings.

In most cases, post-processing isn’t required after laser engraving, as it provides a finished and durable mark.