- Capabilities

-

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

Home > CNC Machining Materials > Metals > Alloy Steel

CNC Machining Materials

Alloy Steel CNC Machining

Alloy steels contain other alloying elements along with carbon, resulting in improved solidity, toughness, fatigue and wear resistance.

All uploads are secure and confidential

Alloy Steel CNC Machining

Alloy steel is one of the steel alloys containing different elements such as molybdenum, manganese, nickel, chromium, vanadium, silicon, and boron. These alloying components are included in increased stamina, solidity, wear resistance, and toughness. The amounts of alloying elements may range from 1 to 50%.

Common alloy steel types used for CNC machining are 4140 and 4340.

They have good strength and toughness, which can be further enhanced through quenching and tempering.

4140 is suitable for manufacturing bearings, gears, shafts, and mechanical components. 4340 has better hardness and strength than 4140. 4340 is typically used for manufacturing high-strength, high-load-bearing, and highly wear-resistant parts, such as aircraft engine components, automotive transmission shafts, and construction machinery parts.

Alloy Steel Subtypes

| Ultimate tensile strength | Yield strength | Young’s modulus (modulus of elasticity) | Elongation at break | Corrosion resistance | Magnetism | Weldability | Application | ||

| Alloy Steel 4140 | 355 – 370 MPa | 230 MPa | 208 – 216 GPa | 18 – 26 % | Moderate to Poor | Semi-Magnetic | Moderate | Heavy duty shafts Connecting rods High tensile bolts | Learn More |

| Alloy Steel 4340 | 690 – 1080 MPa | 470 – 630 MPa | 205 – 213 GPa | 15 – 22 % | Moderate to Poor | Semi-Magnetic | Moderate | High tensile applications General engineering parts Connecting rods & bolts | Learn More |

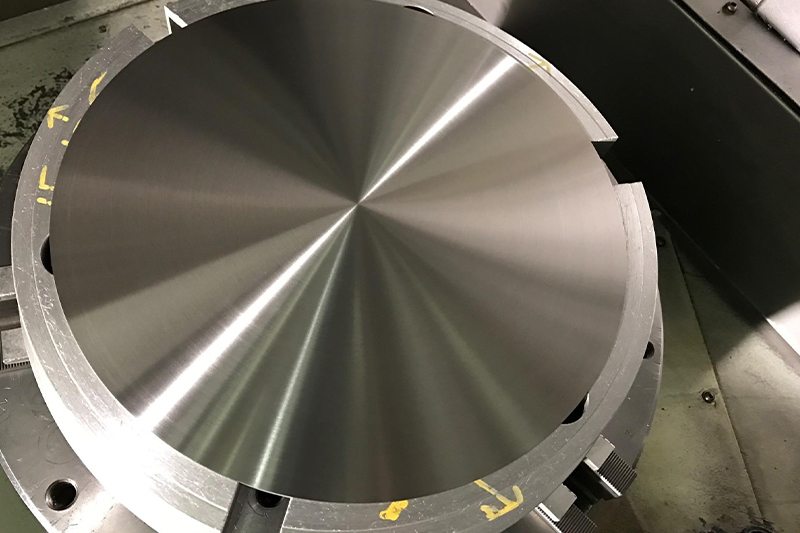

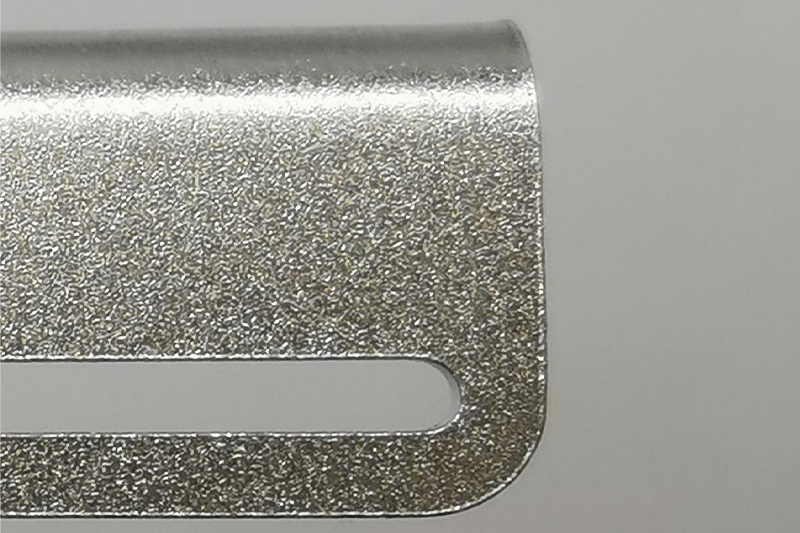

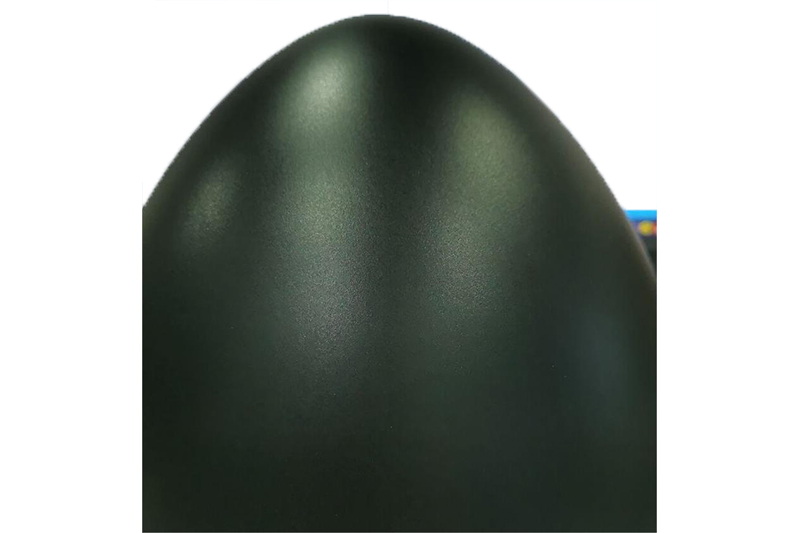

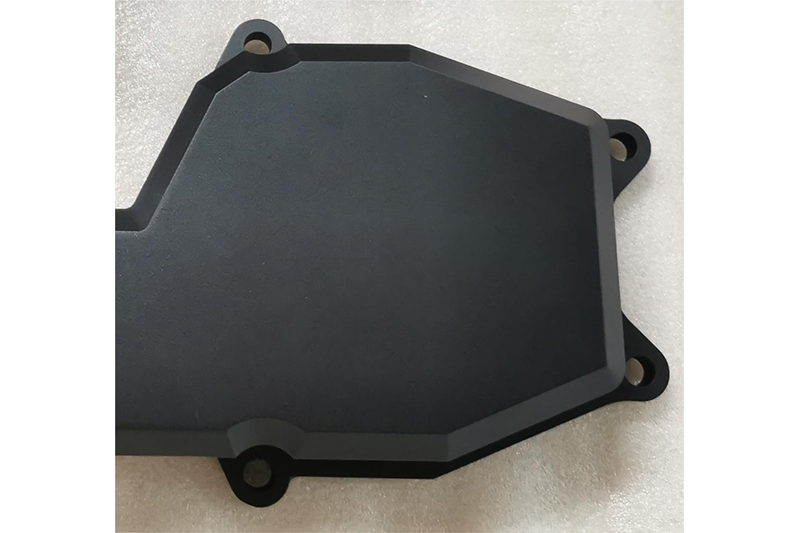

Alloy Steel CNC Machining Surface Finishes

Cost-saving Design Tips

Steel is one of the cheapest materials suitable for CNC machining. However, take care to avoid unnecessary machining costs. Below are some cost-saving design tips:

1.Material selection

Inexpensive though it may seem, it is necessary to select the best steel for your particular application. Utilizing high-strength alloy steel where moderate steel will certainly work increases costs for no included advantage.

2.Part setup

Designing a part to reduce the variety of machining setups can considerably reduce the cost of production. This is particularly true when machining low-cost materials as any cost savings on the material can be quickly removed by costly configurations.

FAQs

Common alloys include 4140 and4340, known for their strength and toughness.

Yes, heat treatment can further enhance the mechanical properties of alloy steel parts.