Home > CNC Machining Materials > Metals > Bronze

CNC Machining Materials

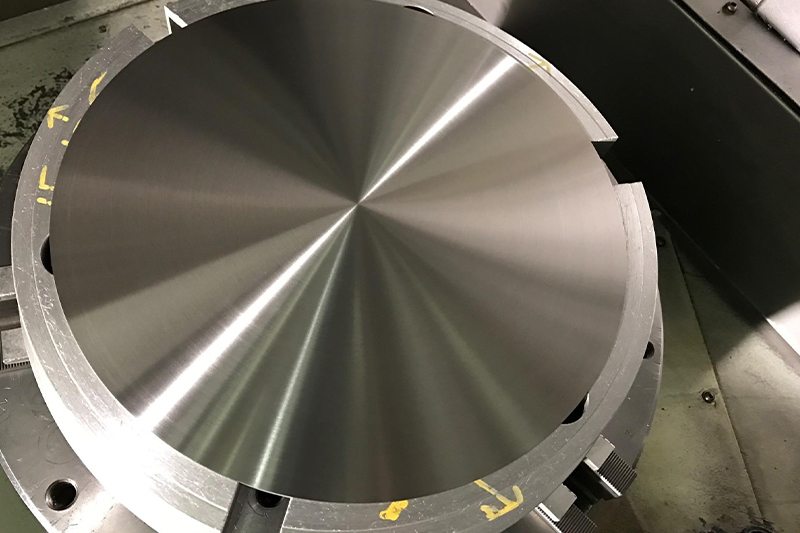

Bronze CNC Machining

Bronze is excellent for applications such as bearings in addition to marine applications on pumps and fittings where corrosion resistance versus seawater is needed.

All uploads are secure and confidential

Bronze CNC Machining

Bronze is made by blending copper with as much as approximately 35% tin and as much as 8% lead. The addition of lead alloy, a soft metal, makes it so machinable. Bronze is terrific for applications such as bearings in addition to aquatic applications on pumps and installations where corrosion resistance against salt water is called for.

This product’s mechanical buildings do not quite measure up to lots of various other machinable metals, so it is best-made use of low-stress elements made with CNC machining.

Bronze, brass, and various other copper alloys have a range of important electrical, mechanical, and corrosion-resistant residential or commercial properties. Especially, bronze has superb machinability, with an index of 100%.

It likewise has reduced rubbing buildings that make it suitable for parts that undergo continual frictional call.

C932: Known as bearing bronze, it has good wear resistance, corrosion resistance, and mechanical properties. C932 contains a small amount of lead, enhancing its machinability. It is widely used to manufacture bearings, bushings, gears, slide bearings, and other mechanical parts that require wear-resistant materials.

Bronze Subtypes

| Ultimate tensile strength | Yield strength | Young’s modulus (modulus of elasticity) | Elongation at break | Corrosion resistance | Magnetism | Weldability | Application | ||

| Bronze C932 | 125 MPa | 110 MPa | 125 – 135 GPa | 20 % | Semi-magnetic | Poor | Bearings, Bushings,Thrust washers. | Learn More |

Bronze CNC Machining Surface Finishes

Cost-saving Design Tips

Bronze is a costly material and therefore its use must be optimized as much as possible.

1.Design for manufacturing

F\Following design for manufacturing principles is just one of the simplest means to minimize prices in the machining procedure. Bronze is much more flexible in complicated features due to its machinability, yet there is a limit and this requires to be comprehended prior to manufacturing starts.

2.Tolerancing

Bronze is easy to equipment. Do not negate the production financial savings by over-tolerancing the part. This includes substantial extra costs to the machining.

FAQs

Bronze has extremely high machinability. External CNC machining can be performed at relatively fast speeds, whereas slightly slower speeds are recommended for boring or drilling and very slow speeds for reaming.

When CNC machining bronze it can reach high temperatures when drilling and turning so the use of a coolant is recommended.