- Capabilities

-

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

Home > CNC Machining Materials > Plastics > GR-10

CNC Machining Materials

G10 CNC Machining

G-10 is a high-pressure fiberglass laminate with a high strength, low moisture absorption, and high level of electrical insulation and chemical resistance.

All uploads are secure and confidential

G10 CNC Machining

Garolite G-10 (also known as phenolic and epoxy-grade industrial laminate) is a composite material with a low coefficient of thermal expansion.

G10 CNC machined parts are known for their excellent electrical insulating properties, mechanical strength, and dimensional stability.

Additionally, it does not absorb water and is an excellent insulator, which makes it useful for electronics applications.

G10 Properties

| Ultimate tensile strength | Yield strength | Young’s modulus (modulus of elasticity) | Elongation at break | Hardness | UV resistance | Application | ||

| G-10 | 260 – 310 MPa | NA | 12 – 14 GPa | NA | 100 – 110 HRM | NA | Terminal boards Electronic test equipment Electric rotor insulation High humidity applications | Learn More |

G10 CNC Machining Surface Finishes

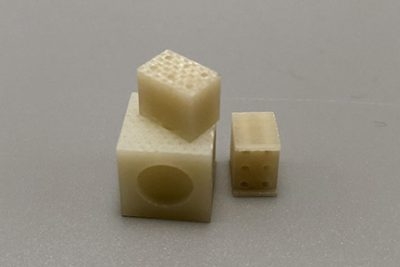

G10 CNC Machining Gallery

Cost-saving Design Tips

To reduce costs, limit part setups numbers, inspection dimensions or tight tolerances numbers, and deep pockets with small radii.

FAQs

G-10 (also known as phenolic and epoxy-grade industrial laminate) is a high-pressure fiberglass laminate, a type of composite material with a low coefficient of thermal expansion. It is a flame resistant composite material used by many aerospace companies. It is also a strong material that does not absorb water which makes it an excellent insulator and really useful for electronics applications.

G10 and aluminum are comparable in strength and durability. G-10 is a little lighter and more resistant to temperature change. Aluminum is quite a bit more rigid and is more resistant to impact.

The difference between G10 and FR4 is that FR4 is a fire-retardant grade of G10 and it can be safely substituted when G10 is called out.

G10 is a fiberglass material that is most often used in the making of circuit boards. It is more stable and resistant to corrosion due to not being a metal. It is generally used in the medical, aerospace, and marine industries.

They are both phenolic laminates. However, Garolite is a brand name for G10, which is a fiberglass laminate. Other phenolics are made with paper, linen or other woven fabrics.