- Capabilities

-

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

Abundant Surface Finishes Services

The easiest way to source your custom parts, with 20+ surface finishing options. Get your parts bead blasted, anodized, or powder coated.

All your designs are secure and confidential

| Type | Sub Type | Photo | Applicable To | Machining Marks | Cosmetic Availability | Color | Tolerances |

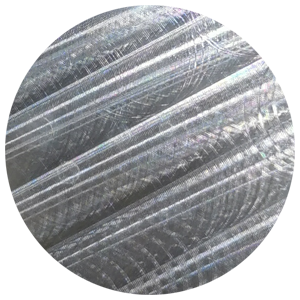

| As Machined | As Machined Ra 1.6 |  | Metals | Visible, light surface scratches | No | NA | Tolerances not affected |

| As Machined Ra 3.2 |  | Plastics | Visible, light surface scratches | No | NA | Tolerances not affected | |

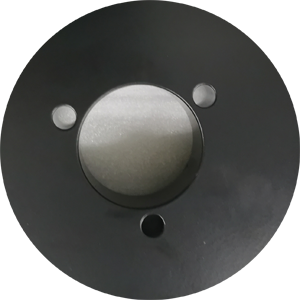

| Mechanical Finishes | Beadblasting |  | Metals | Removed on primary surfaces | On request | NA | Not affected except for specific features |

| Mechanical Polishing |  | Metals, PMMA, PC | Removed on primary surfaces | Always cosmetic | NA | Met after polishing | |

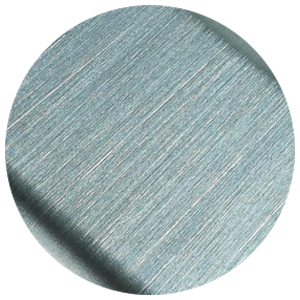

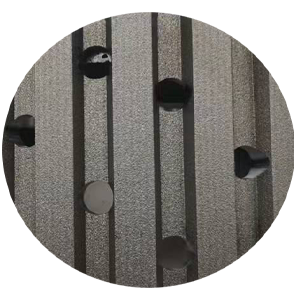

| Brushing |  | Metals | Removed on primary surfaces | On request | NA | Met after brushing | |

| Media Tumbled |  | Aluminum,Steel | Reduced but visible | On request | NA | Met after tumbled | |

| Anodize | Type Il Anodize |  | Aluminum | Reduced but visible | On request | Clear, Black, Pantone | Met after anodizing |

| Type Ill Hardcoat Anodize |  | Aluminum | Visible under anodizing | No | Black, Natural | Met after anodizing | |

| Chemical Finishes | Passivation |  | Stainless Steel, Copper | Reduced but visible | No | NA | Met after passivation |

| Black Oxide |  | Copper, Steel | Visible | No | Black | Met after coating | |

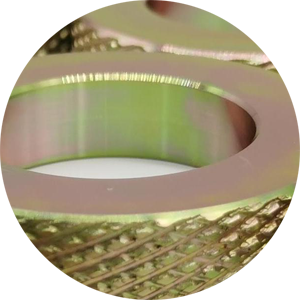

| Chromate Conversion |  | Aluminum | Visible | No | Clear,Gold | Met after coating | |

| Electroless Nickel |  | Aluminum,Steel | Reduced but visible | No | Metallic (semi-bright) | Met after plating | |

| Electropolishing |  | Aluminum,Steel | Removed on primary surfaces | Always cosmetic | NA | Met after electropolishing | |

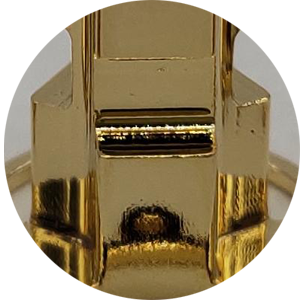

| Electroplating | Gold Plating |  | Steel, Copper | Polishing before plating | Always cosmetic | Gold | Met after electroplating |

| Silver Plating |  | Steel, Copper | Polishing before plating | Always cosmetic | Silver | Met after electroplating | |

| Zinc Plating |  | Steel, Copper | Polishing before plating | Always cosmetic | Natural,Black, Colorful | Met after electroplating | |

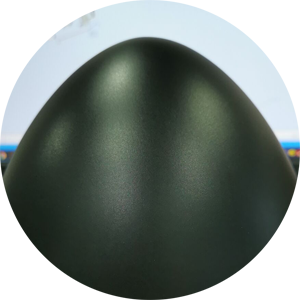

| Spray Coating | Powder Coating |  | Metals | Removed | Always cosmetic | Black, White, Pantone | Met after powder coating |

| Painting Spray |  | Metals | Removed | Always cosmetic | Black, White, Pantone | Met after painting spray | |

| Teflon Coating |  | Metals | Removed | Always cosmetic | Black | Met after Telfon coating | |

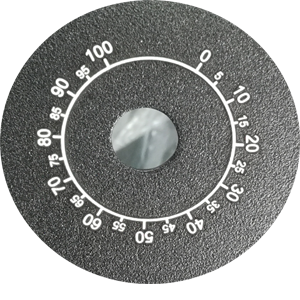

| Part Marking | Laser Engrave |  | Metals, Plastics | Visible | No | NA | Tolerances not affected |

| Silk Screening |  | Metals, Plastics | Visible | No | NA | Tolerances not affected | |

| Heat Treatment | Heat Treatment |  | Steel | Visible | No | NA | Met after heat treatment |

Cosmetic Finishes

Surface finishes serve dual roles, either functional or aesthetic. When they accomplish both, they are termed cosmetic finishes, ideal for enhancing the appearance of cosmetic parts. Ensuring flawless cosmetic part production involves taking extra precautions to minimize imperfections such as hang marks and tool-induced scratches.

Non-cosmetic

Primary machining marks will still be visible.

- As Machined Ra 1.6

- As Machined Ra 3.2

- Type Ill Hardcoat Anodize

- Passivation

- Black Oxide

- Chromate conversion coating(Alodine)

- Electroless Nickel

- Laser Engrave

- Silk Screen

- Heat Treatment

Cosmetic On Request

Finishes can be either cosmetic or non-cosmetic as per request.

- Beadblasting

- Brushing

- Media Tumbled

- Type Il Anodize

Cosmetic By Default

These finishes will always serve a cosmetic function.

- Hand Polishing

- Electropolishing

- Gold Plating

- Silver Plating

- Zinc Plating

- Copper Plating

- Powder Coating

- Painting Spray

- Teflon Coating

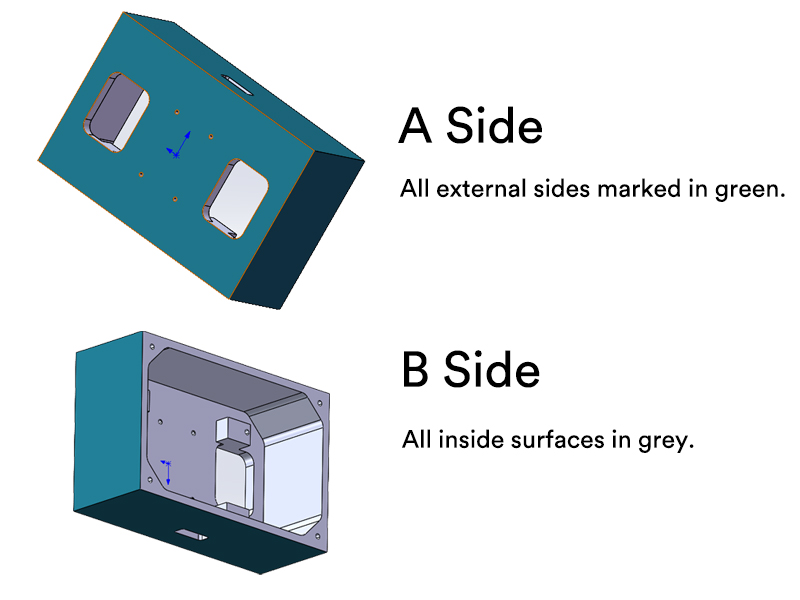

Defining an A and a B side

Surface finishing processes can introduce aesthetic imperfections on your parts, such as hang marks in the case of anodizing. To maintain a pristine appearance in critical areas, consider defining an A-side and B-side in your design:

A-side:

This represents the most visually significant surface, typically the one seen by users.

B-side:

This refers to the less critical surface, usually hidden from view after assembly.

We guarantee defect-free production for the primary A-side of your part. Meanwhile, minor defects like hang marks may be present on secondary B-side surfaces. Rest assured, both A-side and B-side surfaces will be free of scratches, stains, and blemishes.

Will The Part Have

Primary Surface

(A-side)

Secondary Surface

(B-side)

Scratches, stains, blemishes

No

No

Hanging marks

No

Minor hanging marks

Other minor defects

No

Up to 2 minor defects