- Capabilities

-

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

Home > Sheet Metal Fabrication Materials >Spring Steel

Sheet Metal Fabrication Materials

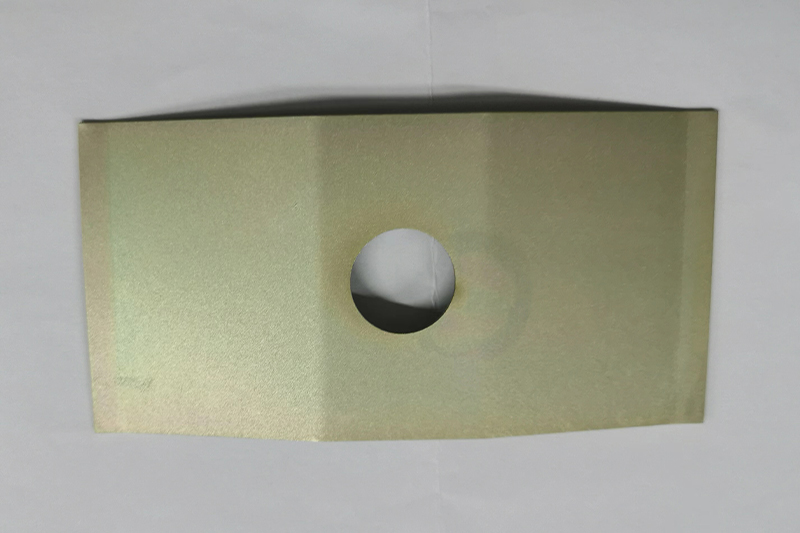

Spring Steel Sheet Metal Fabrication

65Mn is a high carbon with manganese to boost hardenability. It has good wear resistance and great workability.

All uploads are secure and confidential

Spring Steel Sheet Metal Fabrication

The group of spring steel includes several high-yield strength steels consisting of low-alloy manganese, medium-carbon steel, or high-carbon steel. They are largely made use of to manufacture springtimes as the steel will certainly go back to its initial form after turning or load bearing. Carbon steel can be used for small springtimes, yet huge springtimes are best when an alloy is utilized. High carbon spring steel is a typical selection, inexpensive, and quickly processed. It is not fit for extreme temperature levels or for shock/ impact lots. Alloy spring steel is well suited to shock or affect lots or problems with high anxiety. Stainless spring steel can be utilized in some kinds at very high heat (288 ° C) and is corrosion resistant.

65Mn is a high carbon with manganese to enhance hardenability. It has great wear resistance and good workability.

Spring Steel Sheet Metal Fabrication Surface Finishes

Spring Steel Sheet Metal Fabrication Advantages & Disadvantages

Advantages

- High yield strength, resisting distortion when twisted or compressed

- Products can withstand continuous twisting, compression etc and return to original shape

- Good hardness, elasticity, and hardenability

Disadvantages

- Some metals can have issues when overheated including brittleness

- Requires tempering after heating and quenching to relieve material stresses

- Not all are well suited to welding

- Difficult to form in hardened and tempered state

Spring Steel Sheet Metal Fabrication Application

Spring

Valve springs,clutch springs, brake springs,Coil springs, leaf springs, and s-tines

Wire

Piano wire, guitar strings, precision tool wires

Other

Antennas, scrapers,blades,lock picks,grinder spindles