Teflon Coating Services

Teflon Coating

Polytetrafluoroethylene (PTFE) finish, generally called Teflon, is readily available in powder and liquid forms and is used across the industrial landscape. Some PTFE applications only need one layer, yet others need both a coat and an overcoat to ensure optimal security. The surface can be applied to a range of steels consisting of steel, aluminum, and magnesium.

PTFE-coated parts have non-stick surface areas, a low coefficient of friction, and are very resistant to abrasions. Considering that PTFE covering has low porosity and surface area energy, layered components will be immune to water, oil, and chemicals. PTFE can also hold up against temperatures as much as 500 ° F, can be quickly cleaned, and provides terrific electric insulation and chemical resistance.

| Applicable Materials | Surface Preparation | Colors | Cosmetic Availability | Visual Appearance |

| Steel,Aluminum | As machined (Ra 1.6μm) | Black | On request | Parts are Teflon coated directly after machining. |

Teflon Coating Parts

Aluminum Teflon Coating Part

Aluminum Teflon Coating Part Detail

Teflon Coating Process

1 Preparation: Clean and prepare the part’s surface to remove contaminants and ensure proper adhesion.

2 Masking (Optional): If certain areas should remain uncoated, mask or protect them with tape or other materials.

3 Primer Application: Apply a primer coat to improve Teflon adhesion and enhance the coating’s durability.

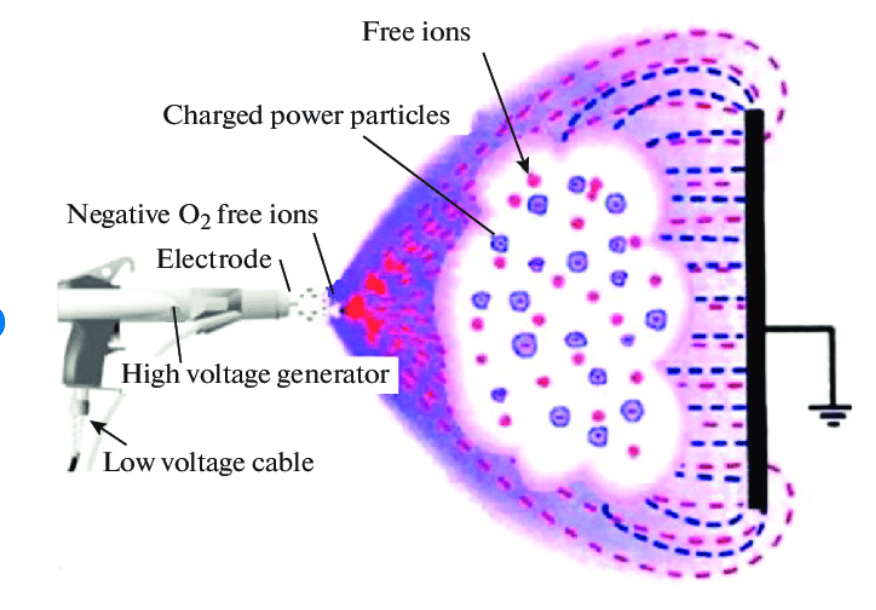

4 Teflon Coating Application: Use a spray or dip method to apply the Teflon coating evenly to the part’s surface.

5 Curing/Baking: Heat the coated part to cure and bond the Teflon to the surface, typically in an oven.

6 Quality Inspection: Inspect the coated part for imperfections and ensure it meets the required standards.

7 Final Drying and Cooling: Allow the part to cool and complete the drying process.

Teflon Coating Design Consideration

- A well-prepared surface ensures better paint adhesion and a smoother finish.

- Mask off areas that should not be painted using painter's tape and protective coverings.

- Conduct a test spray on a small, inconspicuous area to ensure compatibility between the paint and the surface.

FAQs

Teflon coating is available in both liquid and powder forms. Liquid Teflon Coating: Liquid Teflon coating is typically applied using a spray or dip method. It forms a smooth, continuous film when cured, providing a uniform and durable finish. Liquid Teflon coating is commonly used in applications where a consistent and seamless coating is required.

Powder Teflon Coating: Powder Teflon coating is applied through a dry powder application process. The part is coated with Teflon powder, and the coating is then cured through a heating process. Powder Teflon coating can provide a thicker and more robust coating, making it suitable for applications where added durability and chemical resistance are necessary.

Yes, Teflon coating offers excellent heat resistance, making it suitable for high-temperature applications.

No, Teflon coating is an insulator and does not provide electrical conductivity.