- Capabilities

-

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

Home > CNC Machining Materials > Metals > Carbon Steel

CNC Machining Materials

Carbon Steel CNC Machining

High machinability and weldability, high stiffness, low cost.

Can be carburized to increased hardness.

All uploads are secure and confidential

Carbon Steel CNC Machining

As an alloyed steel, carbon steel is the term normally used for alloys of steel that are not stainless. Carbon steel can consist of light steels which are usually cost-effective and very easy to device. Higher-end carbon steels are fairly easy to machine and offer high-wear resistance and tensile toughness.

Mild carbon steel, like 1018 A36 and medium carbon steel S45C, are commonly used for CNC machining. Carbon steel is easy to rust, so anti-rust oil shall be applied for as machined parts or further surface treatments like powder coating are needed.

Carbon Steel Subtypes

| Ultimate tensile strength | Yield strength | Young’s modulus (modulus of elasticity) | Elongation At Break | Corrosion resistance | Magnetism | Weldability | Application | ||

| Mild steel A36 | 400 – 520 MPa | 250 – 290 MPa | 190 – 200 GPa | 21 – 22 % | Poor | Semi-magnetic | Excellent | Structural application,Automotive industry,Heavy equipment,Oil & Gas industry | Learn More |

| Mild steel 1018 | 380 – 450 MPa | 220 – 350 MPa | 190 – 205 GPa | 13 – 25 % | Poor | Semi-magnetic | Excellent | Gears & Pins,Rams & Shafts,Rolls & Sockets,Axles | Learn More |

| Carbon Steel 1045 | 600 – 630 MPa | 310 – 320 MPa | 190 – 205 GPa | 16 % | Poor | Semi-magnetic | High | Axles,Bolts,Forged connection rods,Crankshafts,Torsion bars | Learn More |

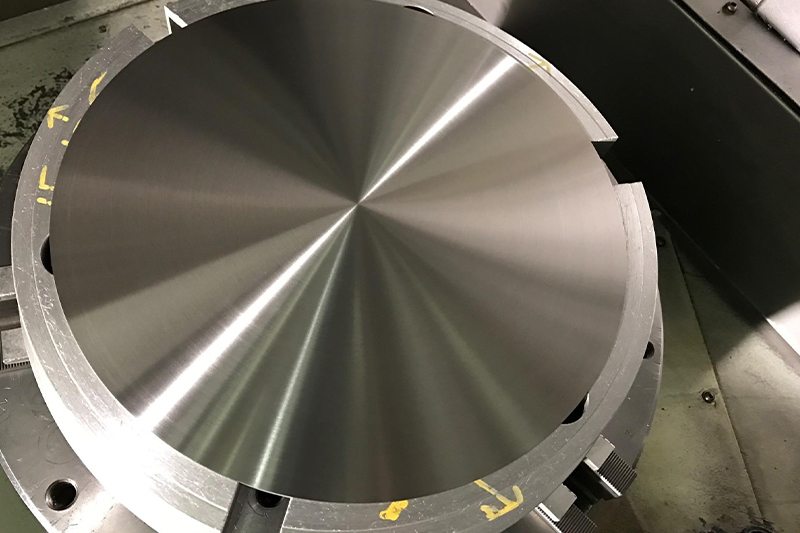

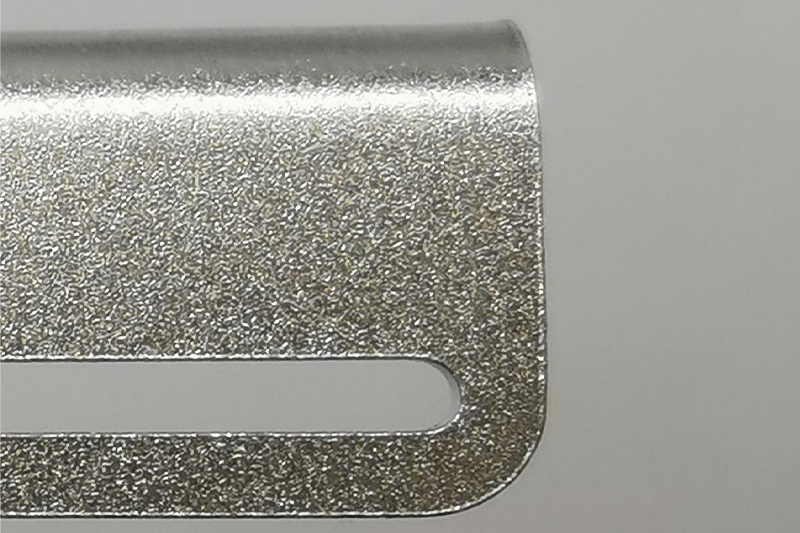

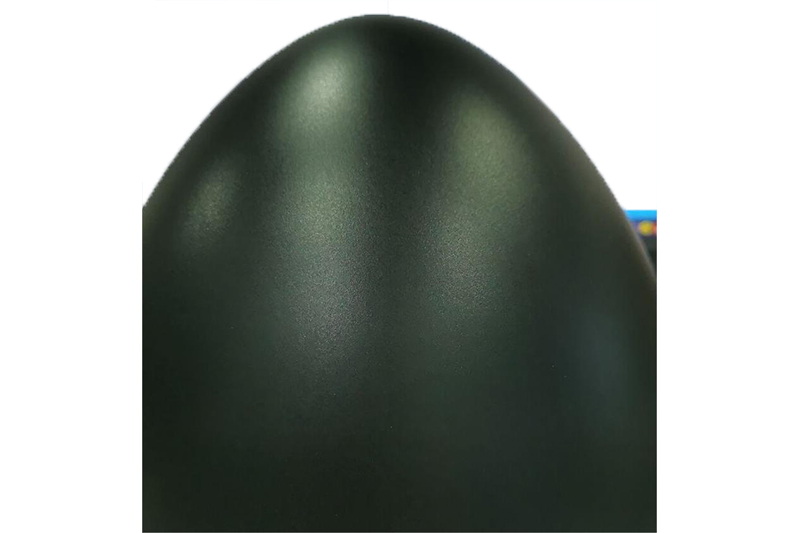

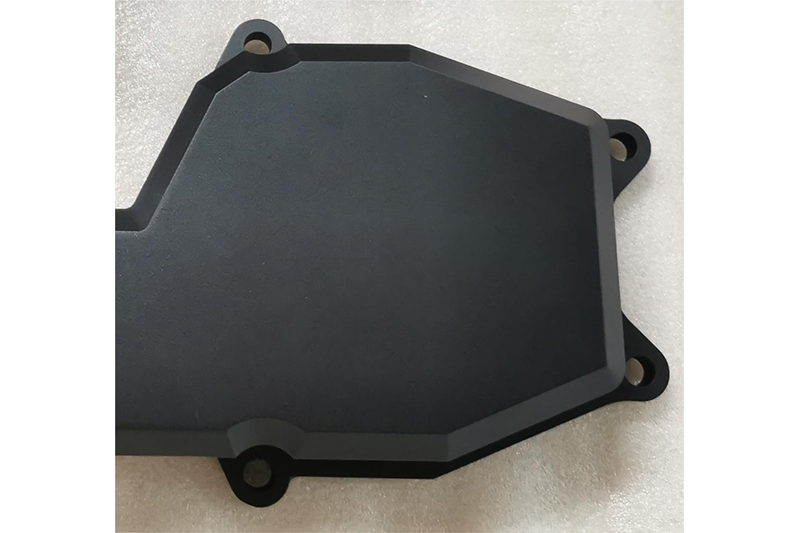

Carbon Steel CNC Machining Surface Finishes

Cost-saving Design Tips

Steel is one of the cheapest materials suitable for CNC machining. However, take care to avoid unnecessary machining costs. Below are some cost-saving design tips:

1.Material selection

Cheap though it may appear, it is essential to pick the best steel for your application. Utilizing high-strength alloy steel where mild steel will certainly work boosts expenses for no included advantage.

2.Part setup

Designing a part to decrease the number of machining setups can considerably decrease the cost of manufacturing. This is specifically true when machining low-cost products as any kind of expense savings on the material can be quickly removed by pricey setups.

FAQs

Two grades of steel are best for machining. The type of parts you need will dictate which grade you choose:

1018 steel is a mild, low-carbon steel that is machinable, weldable, and useful without high strength requirements.

As medium carbon steel, 1045 carbon steel is stronger than low carbon steel but is easy to machine.

Steel is the workhorse of the industry because of its economical cost, wide availability, ease of processing and good mechanical properties. Most steels have good machinability and weldability and take well to heat treatments. Some are stronger and harder than others but most steels offer a combination of toughness and wear resistance.

Steel is a good choice in terms of strength and durability, but its weight is the biggest drawback in comparison to other materials. There are more than 3500 grades of steel to work with and different grades behave differently when being machined. Some types of steel are specifically designed for greater ease when machining. Some steels have high work hardening tendencies and this necessitates the need to keep the machining process moving so there is no unnecessary heat build up.

It is also important to keep tools sharp when CNC machining steel. Other steels, except stainless steel, are prone to rust. Surface treatments are usually recommended.

At ECOREPRAP, we provide mild steel and medium carbon steel machining services, as well as surface treatments.