- Capabilities

-

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

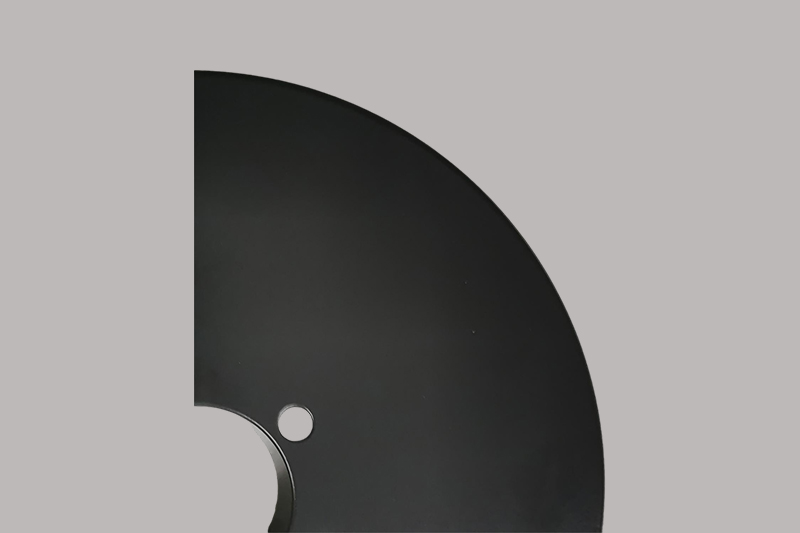

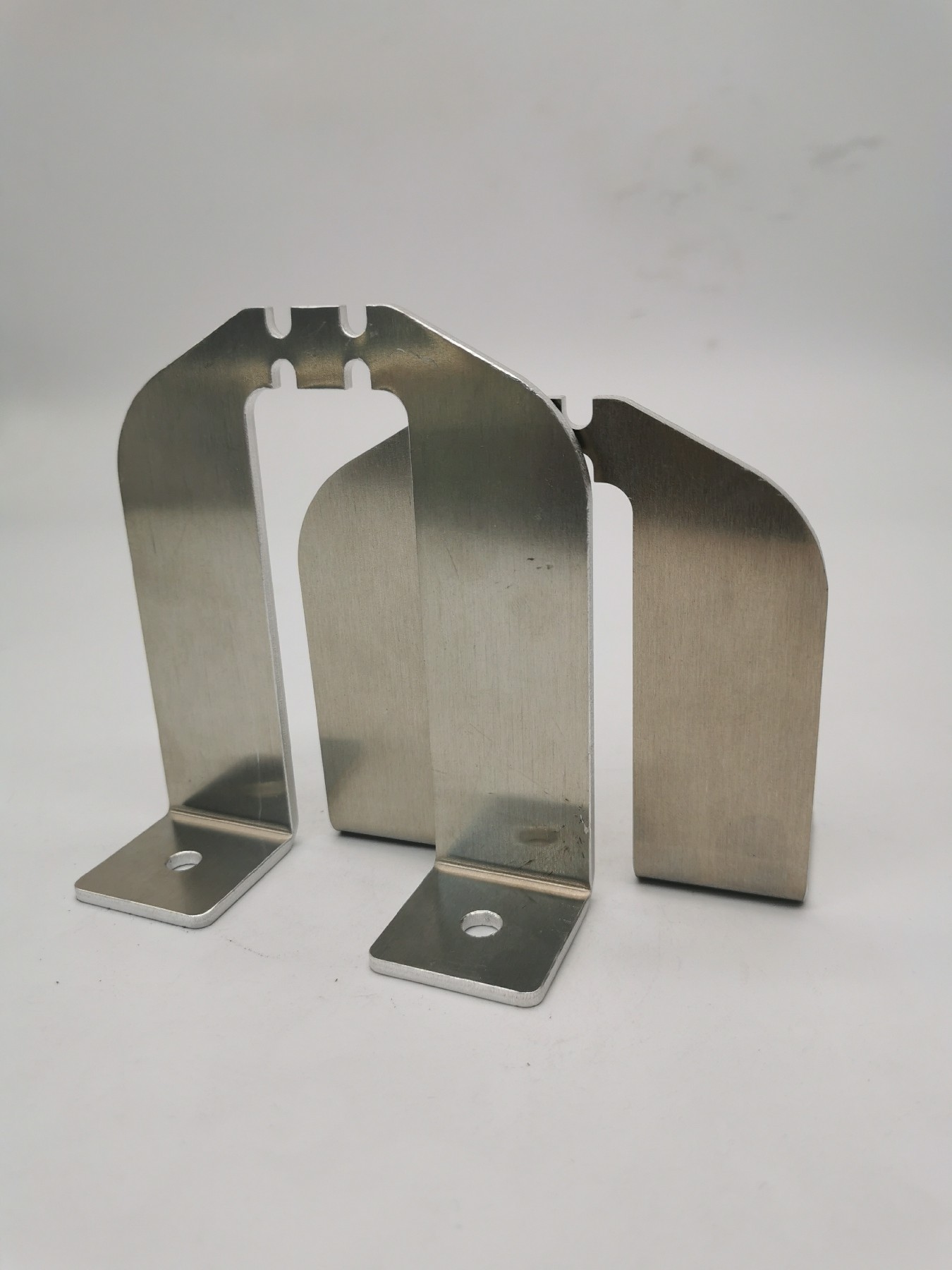

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

Home > Sheet Metal Fabrication Materials >Aluminum

Sheet Metal Fabrication Materials

Aluminum Sheet Metal Fabrication

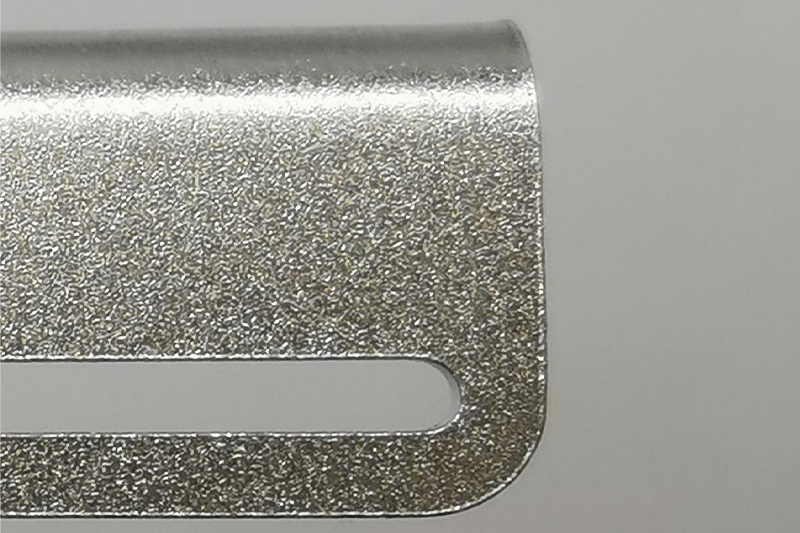

High machinability and ductility, excellent strength-to-weight proportion, excellent electric conductivity, low thickness, and all-natural rust resistance. Always anodized.

All uploads are secure and confidential

Aluminum Sheet Metal Fabrication

Aluminum is a pure metal that is conveniently alloyed with percentages of various other products like copper, manganese, silicon, or magnesium. It is not magnetic or combustible and is a great conductor of power. Lightweight aluminum supplies good rust resistance and is typically very easy to create and process. It comes in numerous different grades and is commonly utilized as a result of its weight. It considers about 1/3 of other products like iron, steel, copper, and brass. It conducts warmth well and is safe making it a great selection in a selection of applications.

AL 5052 is the highest possible stamina non-heat-treated aluminum alloy and supplies excellent exhaustion resistance. Very practical, AL 5052 can be created right into intricate forms and supplies good saltwater corrosion resistance.

AL1060 is a wrought alloy with high electrical conductivity, rust resistance, and workability but rather reduced mechanical stamina. It’s typically used in electrical and chemical industries.

AL6063 is usually utilized for building applications or cutting. It has high-tensile buildings and offers great coating choices. It additionally supplies high rust resistance and is a good choice for anodized applications.

AL 6061 is one of the most versatile heat-treated alloys with excellent workability. It’s well fit to the majority of processes and has excellent rust resistance.

Aluminum Sheet Metal Fabrication Surface Finishes

Aluminum Sheet Metal Fabrication Advantages And Disadvantages

Advantages

- Corrosion immune and typically offers a maintenance-free surface

- Much lighter weight than choices like iron, steel, copper, and brass

- Excellent warmth conductivity

- Safe so it is appropriate for food direct exposure and various other specialized applications

- Non-combustible and reflective so commonly used for lights

- Great formability, workability, weldability, and machineability

Disadvantages

- Much more pricey than steel

- Steel is a far better alternative where strength is a primary worry and weight isn't a problem

- Some alloys are less deterioration-resistant than a stainless steel alternative

- Can affect the preference for food so it's less usual for food or cooking applications

Aluminum Sheet Metal Fabrication Application

Construction

In the construction industry, aluminum is extensively utilized for external facades, walls, roofs, staircases, railings, and shelves. Its minimal mass, high strength-to-weight ratio, durability, and receptiveness to finishes make it an ideal choice for various construction applications. The versatility of aluminum in construction is evident in its ability to contribute to the structural integrity and aesthetic appeal of buildings and infrastructure projects.

Aerospace

Aerospace applications benefit from the diverse range of aluminum alloys, with alloys like 2024 and 2014 playing key roles in fuselage, wing components, and interior framing. The industry values aluminum for its low density, high strength-to-weight ratio, durability, and natural corrosion resistance. Advanced aluminum fabrication techniques, including CNC machining, die casting, forming, and laser cutting, are employed to produce high-quality aerospace components, emphasizing the material's crucial role in enhancing aircraft performance and structural integrity.

Automotive

In the automotive sector, aluminum is a preferred material due to its minimal weight, high strength-to-weight ratio, and inherent corrosion resistance. From engine blocks and transmissions to brake components and frames, aluminum's low mass contributes to improved vehicle efficiency. Common aluminum fabrication methods like CNC machining, die casting, forming, and laser cutting are employed to manufacture various automotive parts, highlighting aluminum's versatility in enhancing both performance and fuel efficiency.

Marine

The marine industry commonly relies on aluminum alloys such as aluminum silicon and aluminum-magnesium for their corrosion resistance, strength, and low density. Aluminum's resilience to saltwater corrosion is vital, and processes like anodizing or painting further enhance its durability. In marine applications, aluminum is prevalent in the construction of ladders, railings, and ship hulls, showcasing its suitability for withstanding harsh maritime environments.

Electronics

In the electronics industry, aluminum's excellent electrical and thermal conductivity, coupled with its low density, make it a preferred material. From automotive and aerospace subsystems to consumer electronics, aluminum is employed in various electronic applications. Its use extends to electrical wiring and components like capacitors, antennas, and heat sinks, underscoring its significance in enhancing the performance and functionality of electronic devices across diverse sectors.