Home > CNC Machining Materials > Metals > Zinc

CNC Machining Materials

Zinc CNC Machining

Zamak 3 is one of the most widely used quality of Zinc readily available and supplies excellent dimensional stability.

All uploads are secure and confidential

Zinc CNC Machining

Zinc (represented as Zn on the periodic table) is a reasonably common non-magnetic metal. It is usually alloyed with aluminum, magnesium, and copper. This course of zinc alloy is referred to by the name Zamak (the term originated as an acronym for the aspect names in German: “Zink, Aluminium, Magnesium, and Kupfer”).

These alloys are usually supplied in the form of ingots as a result of their substantial use in die-casting applications. Zinc has exceptional damping capability; it is extremely ductile and displays long-term dimensional security.

Die-cast Zamak alloys maintain high degrees of accuracy and therefore need much less machining to bring the component into the called for resistances.

Zinc alloy metal is several of the least expensive materials readily available. In spite of an affordable price point, they have good mechanical toughness, are conveniently machined, and withstand mechanical shocks well.

Complex elements are frequently originally die-cast and after that have important functions machined into them, decreasing general CNC machining time and expense. The automotive industry makes substantial use CNC machined zinc alloys.

Zamak 3 is one of the most widely use of the quality of Zinc, offering exceptional dimensional security (together with other physical and mechanical buildings).

Zamak 3 is the Zinc type most used to make zinc CNC machining parts.

Zinc Subtypes

| Subtypes | Tensile Strength | Elongation at Break | Hardness | Density | |

| Zamak 3 (Zinc) | 30,000 PSI | 10% | Brinell 82 | 6.6 | Learn More |

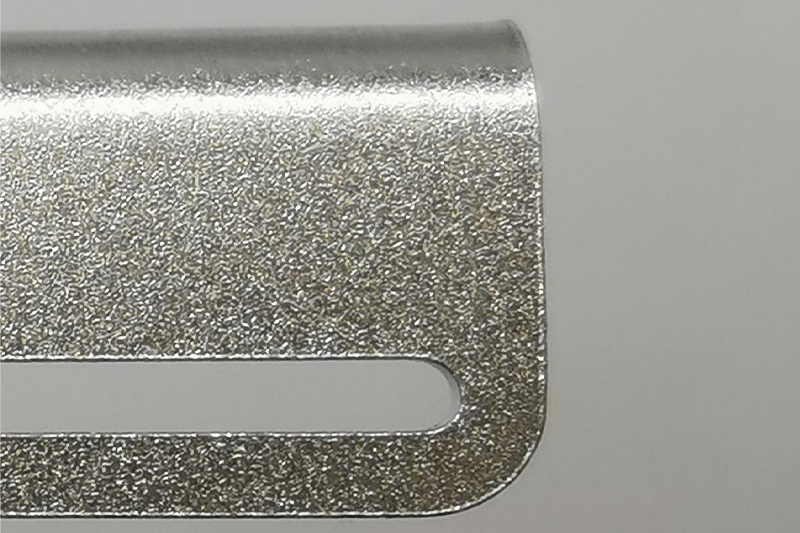

Zinc CNC Machining Surface Finishes

Cost-saving Design Tips

To reduce costs, limit the number of part setups, inspection dimensions or tight tolerances, and deep pockets with small radii.

FAQs

Zamak 3.

Zinc machining is prevalent in the electronics, plumbing, and automotive industries, among others.

Yes, proper ventilation and safety measures are necessary to prevent exposure to zinc fumes during machining.

Yes, zinc parts can be coated with various finishes like powder coating or electroplating to enhance their appearance and functionality.