- Capabilities

-

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

CNC Milling Services

Reliable high quality on-demand CNC milling services for rapid prototypes and low volume parts.

- Tight tolerance up to 0.005 mm

- Milled parts as fast as 1 day

- 3, 4, 5 axis milling

All your designs are secure and confidential

What is CNC milling services?

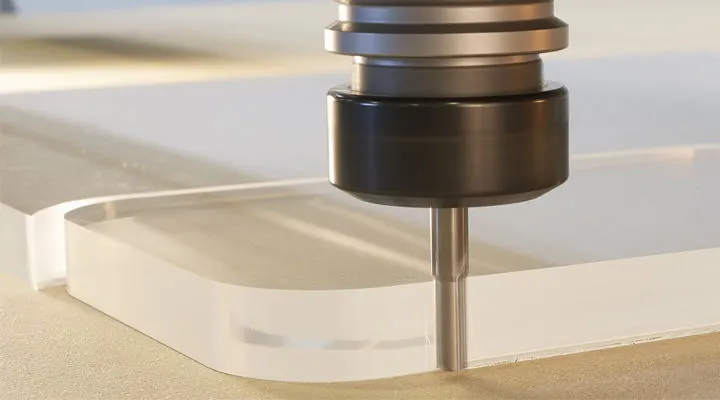

CNC milling uses rotational cutting tools to remove product from a workpiece to produce completed parts and products. This manufacturing procedure works well for numerous steels, polymers, timber, and glass products.

CNC milling systems typically have 3 straight levels of liberty: the X, Y, and Z axis. This allows for first-class precision and description.

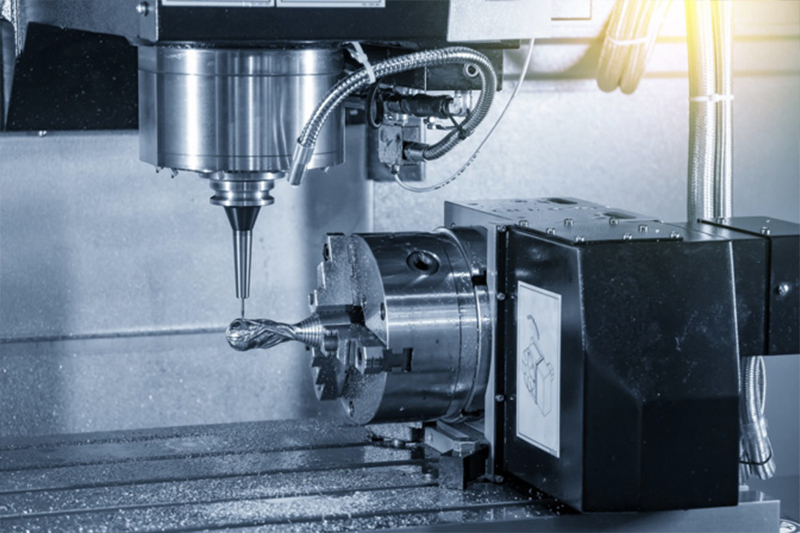

ECOREPRAP likewise supplies CNC milling services with more advanced 5 axis machines, where the tool head and machining bed (A and B axis) can also rotate. 5-axis CNC makers can generate and get rid of high geometric complexity without needing several device arrangements.

Our CNC milling process produces custom prototypes and end-use production parts in as fast as 1 day. We use 3-axis milling,4-axis milling and 5-axis milling processes to manufacture parts from more than 20+ engineering-grade plastics and metals.

With machined production parts, you can also get more competitive pricing at higher quantities in addition to first article inspection (FAI) reporting, material certifications, and additional finishing options like anodizing and chromate plating.

CNC milling services is commonly used to produce the following machined parts:

functional prototypes

jigs and Fixtures

production components in lower volumes

ECOREPRAP CNC Milling Capabilities

ECOREPRAP provides top-notch CNC milling services with 3-axis, 4-axis, 3+2-axis, and continuous 5-axis machining for accurate CNC milling parts. Whether it is for rapid prototyping or end use, ECOREPRAP will be your go-to-manufacturer choice.

3 Axis CNC Milling Services

A 3-axis CNC machine is the most common type with a long history. The 3-axis machining technology is mature, and the 3-axis machining cost per hour is low.

For components with simple design, 3-axis machining services are cost-effective. Some complex parts can also be achieved through multiple setups, which requires a higher level of programming and machining proficiency.

ECOREPRAP offers 3-axis CNC machining services for both metals and plastics at a reasonable price.

4 Axis CNC Milling Services

4-axis CNC machine installs a rotating worktable or rotary head, allowing rotation in multiple axes to achieve multi-sided machining of workpieces. It enables easy machining of bevels, tilted holes, and complex surfaces.

Reducing the clamping times enhances productivity, reduces position errors introduced by multiple clamping, reduces tool wear, and extends tool life.

With ECOREPRAP milling services, you can get machined parts with better surface finish and tight tolerances.

5 Axis CNC Milling Services

CNC 5-axis machining centers usually contain 3+2 axis and continuous 5-axis.

ECOREPRAP has both 3+2-axis machines and continuous 5-axis machines. Our 5-axis CNC milling services will save time, enhance efficiency, and reduce price, ensuring you satisfy market demands quickly and cost-effectively.

Get quick models and low-volume manufacturing for your complicated custom-made CNC-milled parts with a better surface finish.

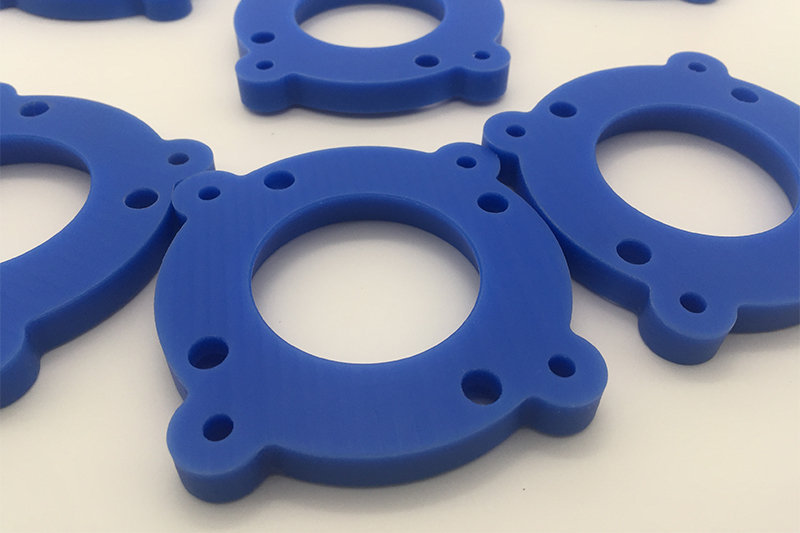

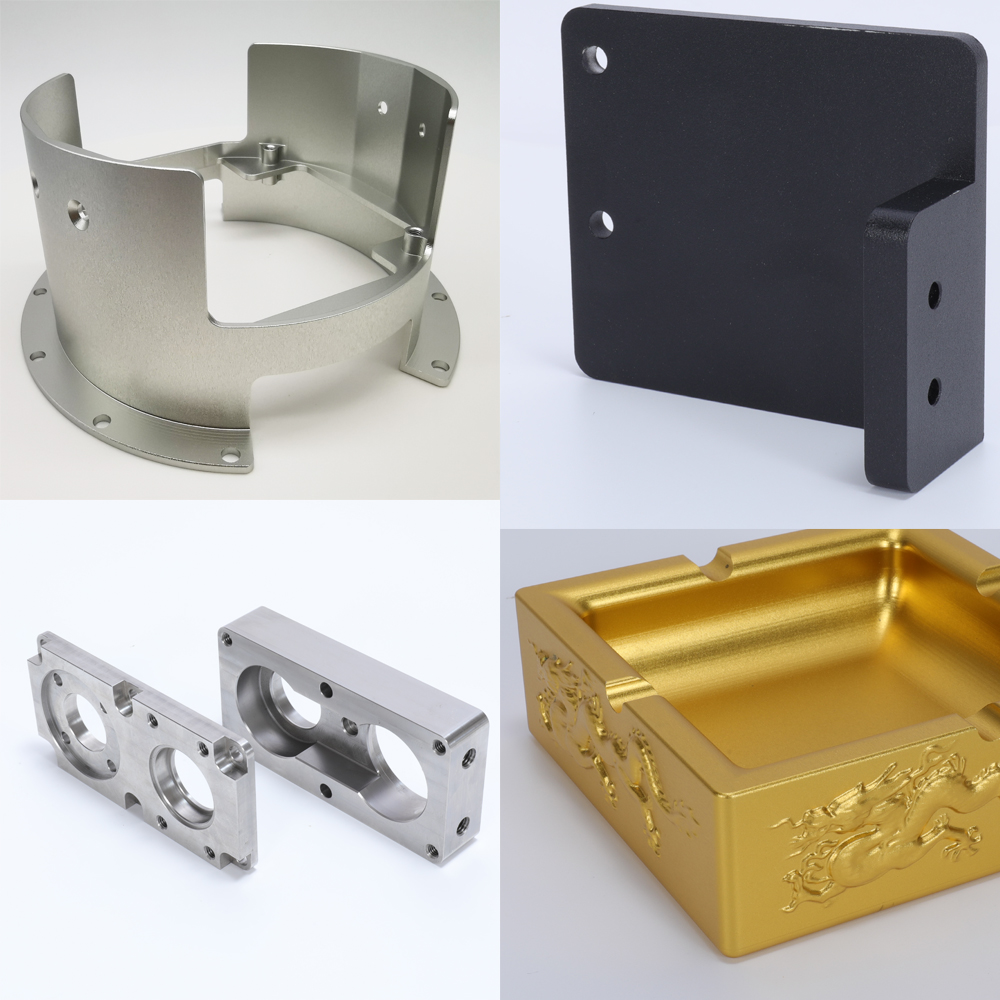

CNC Milling Parts Gallery

CNC Milling Materials

CNC Milling Metals

ECOREPRAP offers more than 80+ metals for your milling parts materials selection, aluminum, carbon steel, alloy steel, stainless steel, tool steel, and many others.

With surface treatments like anodizing, heat treatment, black oxide, you can get the desired properties.

CNC Milling Plastics

ECOREPRAP offers more than 20+ plastic selections for CNC machining, Derlin, acrylic, polycarbonate, ABS, UHMWPE,PP,PEI,PU and more.

Milled plastics are suitable for both prototype development and crafting custom end-use components.

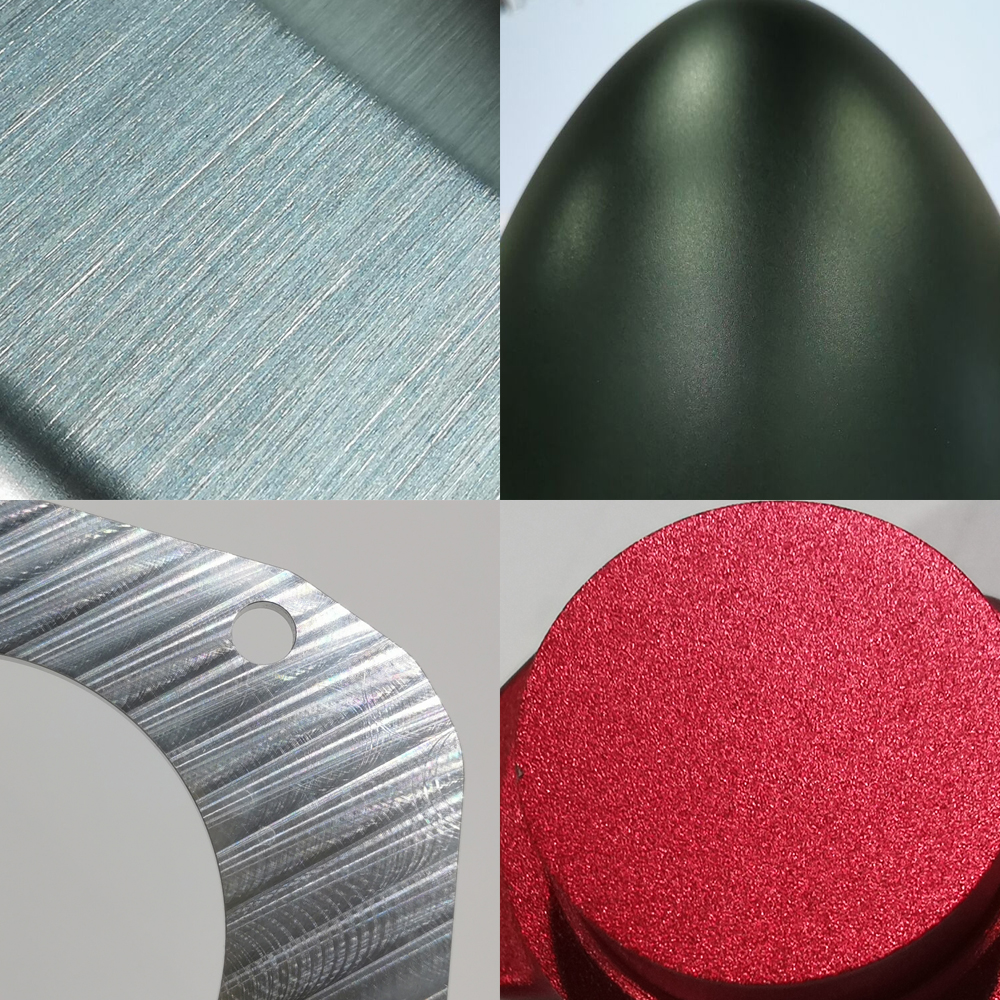

CNC Milling Surface Finishes

ECOREPRAP provides precision CNC milling services and surface treatments to enhance your component’s performance by improving roughness, hardness, chemical resistance, and aesthetics.

ECOREPRAP is your one-stop machining solution provider for your custom parts.

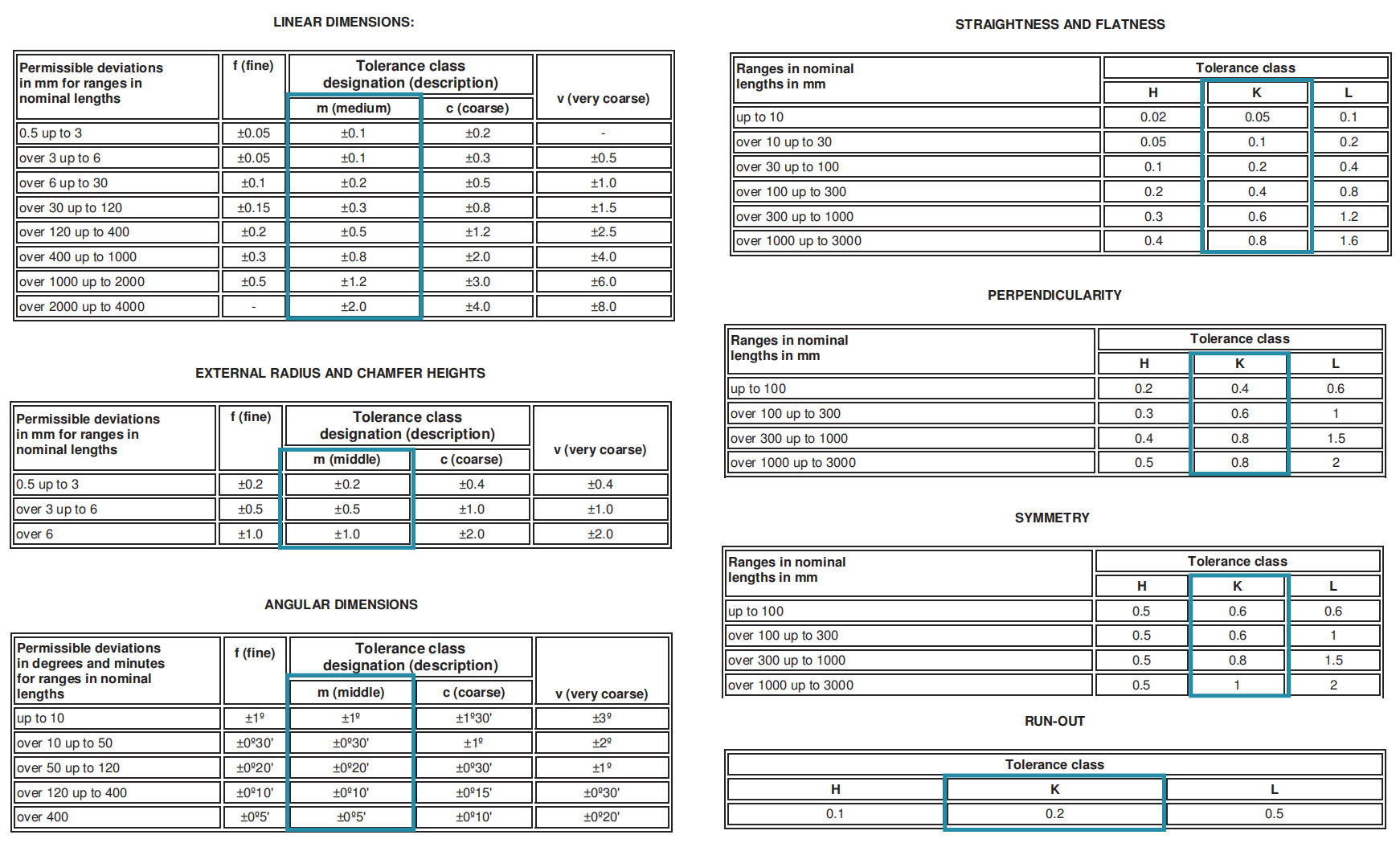

Precision CNC Milling Tolerance

We strictly produce parts according to the tolerances indicated on the customer’s 2D drawings, and the tight tolerance can be up to 0.005mm. Without specific instructions, at ECOREPRAP, we follow the ISO 2768-MK tolerance standards both for turning metals and plastics.

CNC Milling Design Guidelines

Inspect the recommended and practically feasible guidelines for the most common features encountered in CNC machined parts.

Feature

Recommended Size

Feasible Size

Min. feature size

Ø 2.5 mm

Ø 0.50 mm

Internal edges

R 8 mm

R 0.25 mm

Minimum wall

thickness

0.8 mm (for metals)

1.5 mm (for plastics)

0.5 mm (for metals)

1.0 mm (for plastics)

Holes

Diameter: standard

drill bit sizes

Depth: 4 x diameter

Diameter: Ø 0.5

Depth: 10 x diameter

Threads

Size: M6 or larger

Length: 3 x diameter

Size: M2

CNC Milling FAQs

ECOREPRAP works with vertical, horizontal, and multi-axis milling machines. The vertical milling machine is highly accurate equipment that carries out 3-axis milling, suitable for vertical surfaces and angular shapes.Our horizontal milling machines perform 4-axis milling and are suitable for heavy milling operations.

ECOREPRAP have 3-axis, 4-axis, 3+2 axis and continuous 5 milling machines.

Yes, you can combine both manufacturing processes to reinforce your custom parts. Printed parts can be milled to achieve dimensions with tight tolerances or to meet surface quality requirements. Intelligently combining these two methods can ensure faster manufacturing, less waste, and lower costs. It even achieves higher accuracy and precision, repeatability, and sustainable production.

ECOREPRAP milling services can make precise parts with a tight tolerance of 0.005mm.

There are 80+ metals and 20+ plastics materials for choices.

The machining processes differ. CNC milling is suitable for irregular and flat surfaces, while CNC lathe is suitable for cylindrical or conical parts.

For metals, the minimum wall thickness shall be o.5mm, and for plastics, it shall be 1mm. The larger the part size, the bigger the minimum wall thickness shall be. Please remember that this does not imply that wall thicknesses with lesser values are unachievable. These recommendations are simply thresholds to limit the risk of warpage.

If a specific fillet radius is required, please specify. If not, the fillet radii that allow for easy machining will be added based on the machinist’s discretion. For a general idea, internal vertical edge radii could be >1/3*Depth and internal horizontal edges may be left sharp or have a 0.5mm to 1mm radius.

A 5-axis CNC milling machine can move a cutting tool in 5 axes, which allows the operator to simultaneously hit five different sides (or more) of a part depending on the design complexities. Resultantly, the tool is highly capable of creating highly complex products and parts.

With a 5-axis machine, the X, Y, and Z-axes are similar to a 3-axis machine layout. The table then rotates along the A-axis, as with the 4-axis. However, the 5-axis machine involves the pivoting action at the table joint, followed by rotation along the C-axis, which defines the fifth movement.

Check our blog about 5-axis CNC machining here.