- Capabilities

-

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

CNC Machining Materials

ABS CNC Machining

ABS is a usual thermoplastic with all-around excellent mechanical buildings, outstanding effect strength, good warm resistance, and excellent machinability.

All uploads are secure and confidential

ABS CNC Machining

ABS, or acrylonitrile butadiene styrene, is a widely used thermoplastic because of its fairly low cost and superb toughness.

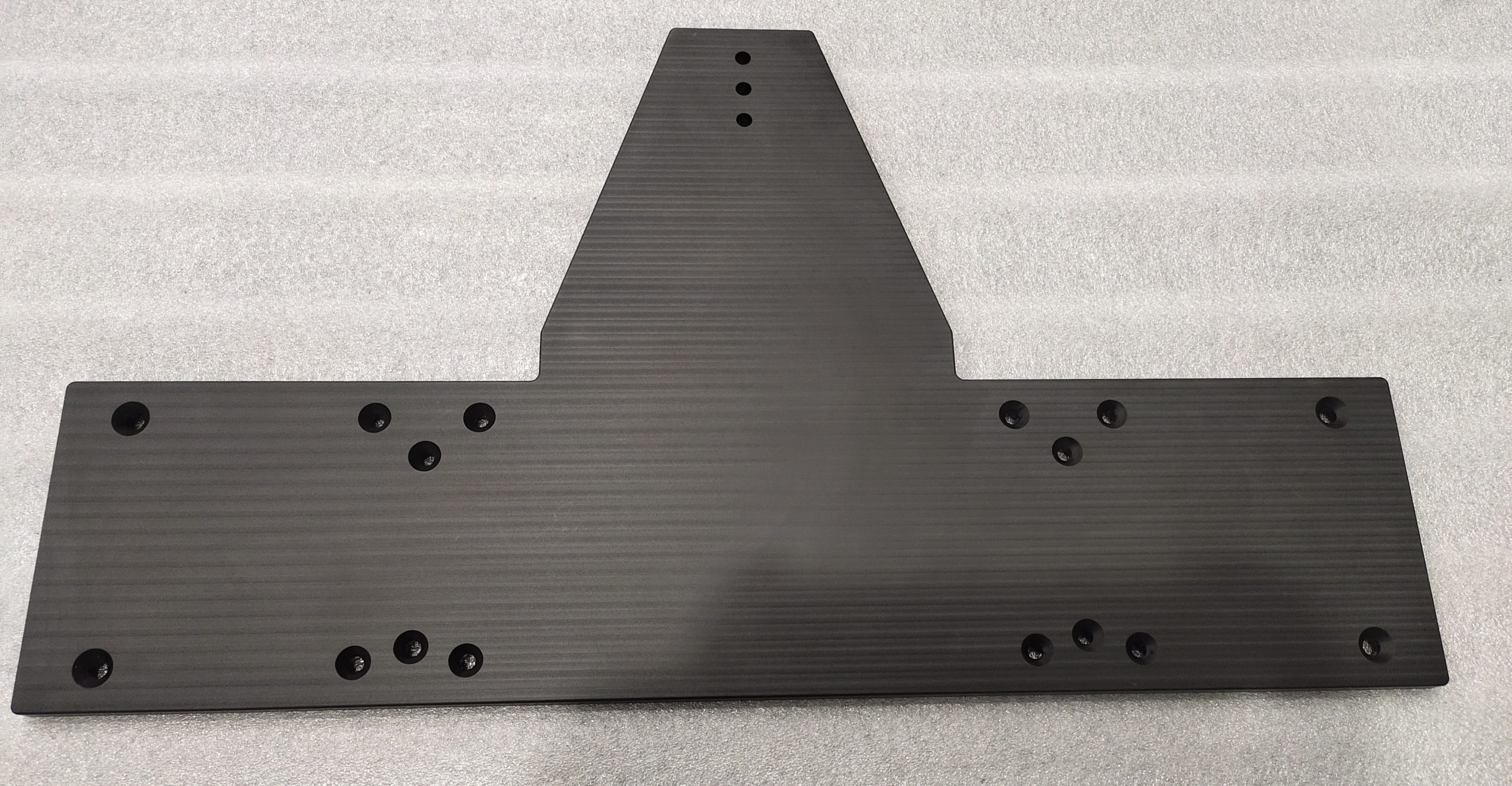

CNC machining is a good way to produce ABS machining parts with custom-made shapes without costly molds and mildews, specifically for prototypes, jigs, and components and low-volume production.

ABS is found in many consumer items and is also extensively used in the auto market. CNC-machined abdominal muscle exhibits amazing durability, rigidity, and shock absorbance features, particularly for such an affordable product.

ABS is suitable for CNC milling and turning.

ABS can undergo various post-processing treatments, including coloring, surface metallization, welding, electroplating, bonding, and more.

Typical applications of ABS parts include automotive applications, instrument panels, pillar trim, door liners, and handles.

CNC machining ABS are available in black, natural yellow, blue and other colors.

ABS Properties

| Ultimate tensile strength | Yield strength | Young’s modulus (modulus of elasticity) | Elongation at break | Hardness | UV resistance | Application | |

| 27.6 – 55.2 MPa | 18.5 – 51 MPa | 1.1 – 2.9 GPa | 10 – 50 % | 5.6 – 15.3 HV | Poor | Automotive applications Instrument panels Pillar trim Door liners and handles | Learn More |

ABS CNC Machining Surface Finishes

ABS CNC Machining Gallery

Cost-saving Design Tips

ABS is a very cheap plastic that is easy to machine and has excellent mechanical properties. To further save costs, engineers can pre-injection mold prototypes. While ABS itself is cheap, molds are not. Once a mold is designed, manufactured, and working as expected, the cost per part becomes miniscule. Before time and money is invested into an expensive mold, however, it’s a good idea to machine a prototype out of ABS to ensure that the part features are rigid and perform as expected.

ABS CNC Machining FAQs

ABS plastic is a low-cost engineering plastic, widely used for pre-injection molding prototypes. CNC machined ABS is a great option for production-like parts, where detail and mechanical properties are important.

White, black, neutral yellow. There may be other colors available in the market.

ABS plastic is an excellent choice for general purpose prototyping, pre-molding prototypes, parts that will receive impact and require toughness, or when low cost is desired.

Yes, flame retardant ABS is special type of ABS. ECOREPRAP provide natural color and black color flame retardant ABS CNC machining.