- Capabilities

-

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

SLS 3D Printing Services

High-quality Nylon parts for prototyping and production easily using selective laser sintering (SLS) 3D printing as fast as 3 days.

All your designs are secure and confidential

What is SLS printing?

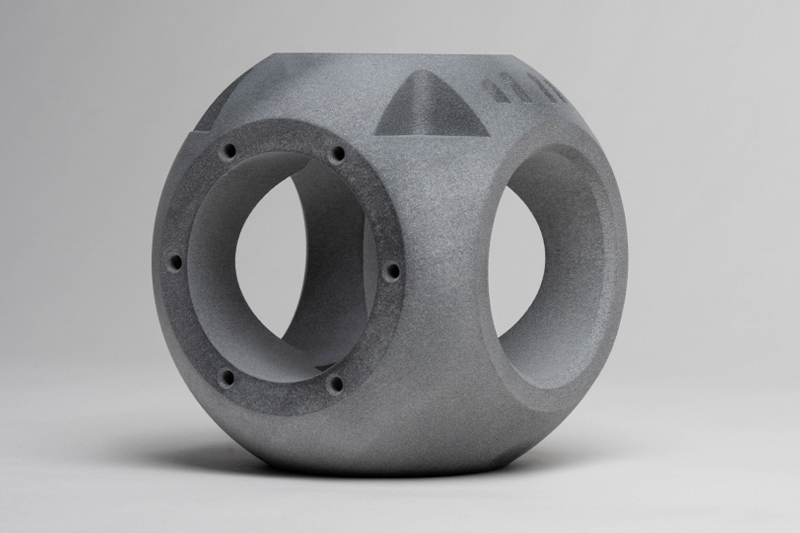

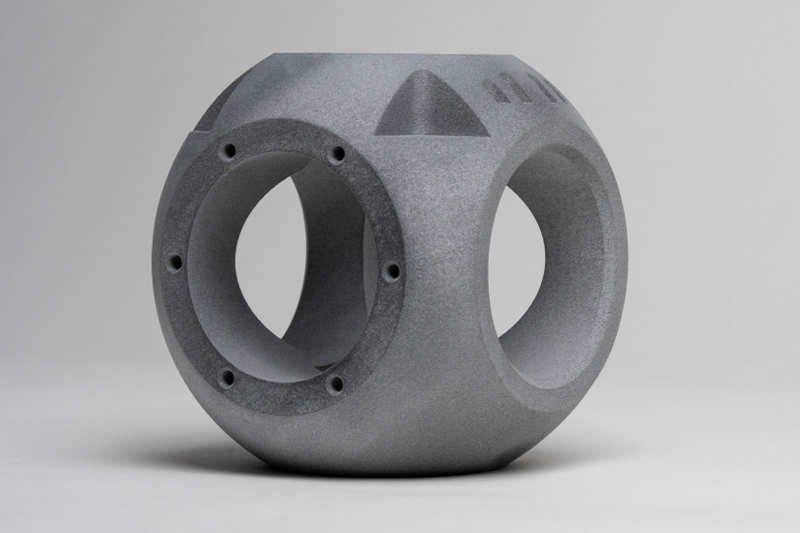

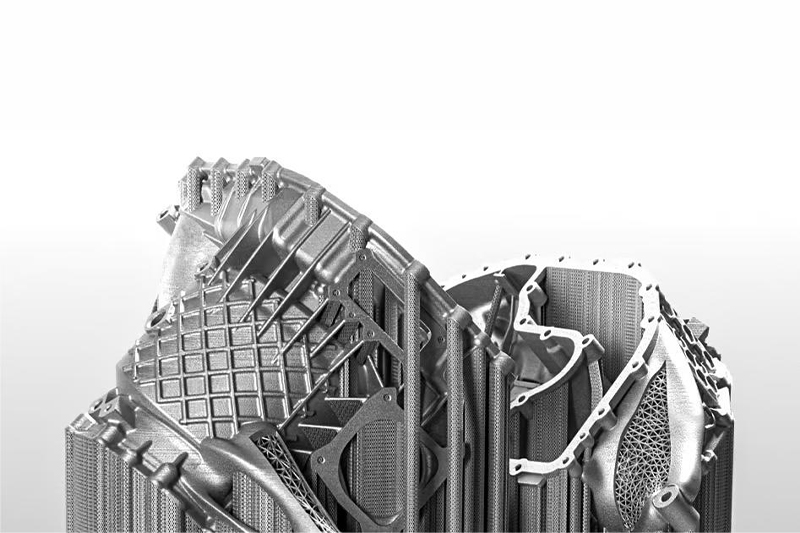

Selective Laser Sintering(SLS) is an industrial 3D printing process that is excellent for making end-use parts. In SLS, a laser selectively sinters polymer powder fragments, fusing them and building a component layer-by-layer. With some of the largest print beds, SLS machines can produce useful plastic to get rid of isotropic mechanical homes for thorough prototyping or low-volume production of end-use parts. SLS is an inexpensive production technique, which our customers consistently pick for the most complex parts and those calling for considerable modification.

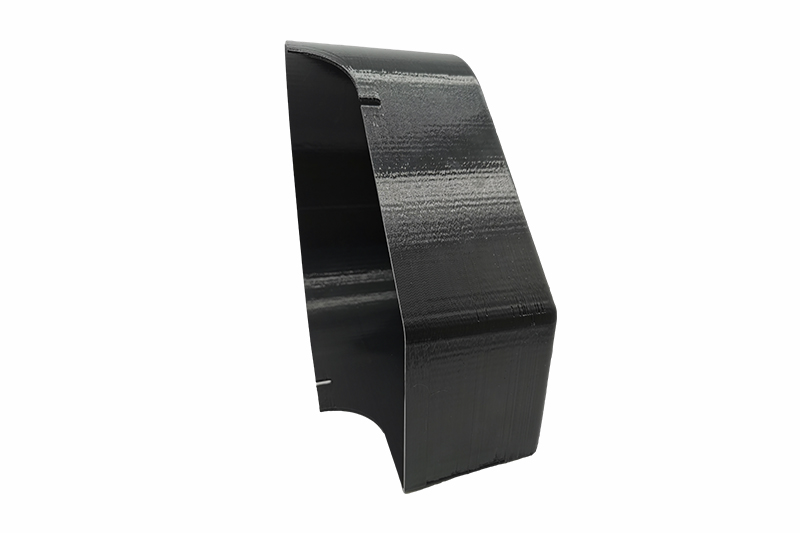

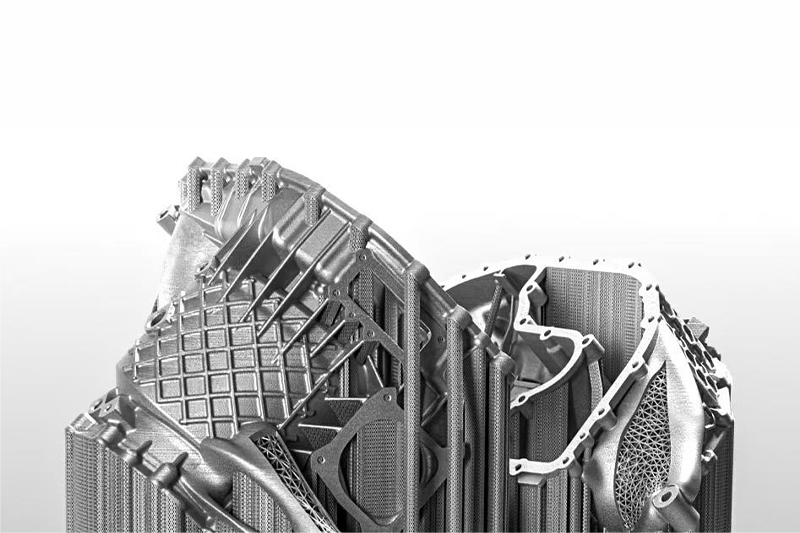

Gallery

SLS 3D Printing Materials

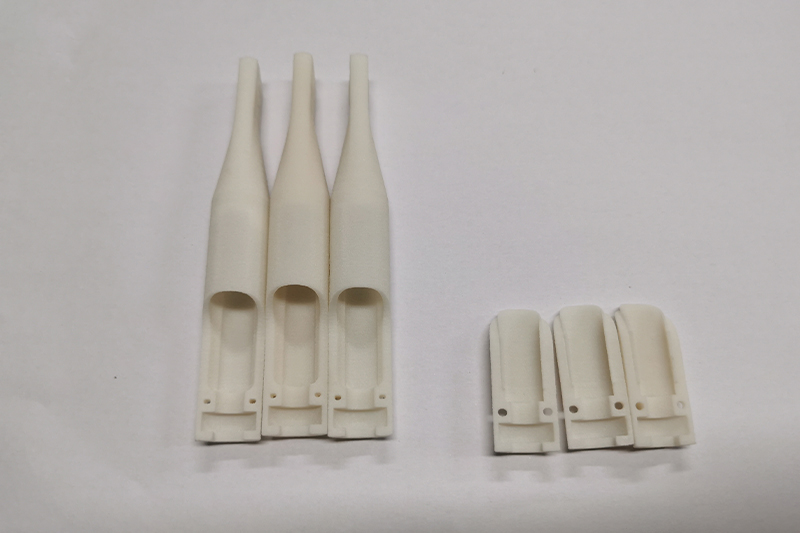

PA12

White, dyed black. Prototypes, detailed and complex parts, fully functional models, and end products.

PA12 glass filled

Off-white.Enclosures and housings, jigs, fixtures, tooling

SLS 3D Printing Finishes

As Printed

Generally white or rock gray, smooth surface area, powder texture, without noticeable layers.

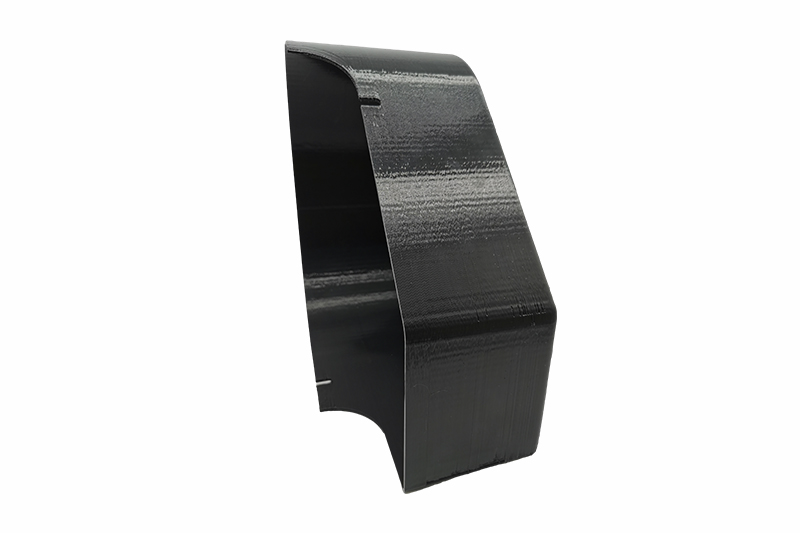

Dyed (black)

Dyed black by immersion in a warm color bath. The color penetration reaches a depth of about 0.5 mm and covers all surfaces.

SLS 3D Printing Tolerance

| Maximum Build Size | Standard Lead Time | Dimensional Accuracy | Layer Thickness | Minimum Feature Size |

| 395 x 500 x 395 mm | 3 business days | ± 0.3% with a lower limit of ± 0.3 mm | 100μm | 0.5 mm |

SLS 3D Printing Guidelines

The table below summarizes the recommended and technically feasible values for the most common features encountered in SLS 3D printed parts.

Browse SLS 3d printing guidelines

Feature

Recommended Size

Unsupported Walls

1.0 mm

Supported Walls

0.8 mm

Minimum Detail Size

0.8 mm

Minimum Hole Size

1.0 mm

Moving Parts

0.5 mm

Assembly Clearance

0.4mm

Maximum Wall Thickness

20 mm

SLS 3D Printing Advantages And Drawbacks

Advantages

• Excellent layer adhesion

• Fast printing process for functional, durable prototypes or end-use parts

• Materials have good mechanical properties

Drawbacks

• As-printed parts are rough to the touch due to surface porosity

• SLS is prone to shrinkage and warping, especially on long, thin parts

SLS 3D Printing Application

Concept Models

The rate and adaptability of SLS printing let product designers create physical pictures of their layouts with the iterative procedure.

Rapid Prototyping

SLS prototyping can be made use of to develop completely functional prototypes, full of relocating parts, as well as all-in-one settings up.

Direct Digital Manufacturing

The high accuracy and consistency of SLS make it an ideal way to build large quantities of discrete or customized parts.

3D Printing Technologies Comparision

| Materials | Dimensional accuracy | Strengths | Build Volume | Layer Thickness | Min. Feature Size | |

| FDM | 3 | ± 0.5% with a lower limit on ± 0.5 mm | Low cost, wide range of materials | 500 x 500 x 500 mm | 100-300μm | 2.0 mm |

| SLA | 3 | ± 0.2% with a lower limit of ± 0.127 mm | Smooth surface finish, fine feature details, big print area | 500 x 500 x 500 mm | 50-100μm | 0.2 mm |

| SLS | 2 | ± 0.3% with a lower limit of ± 0.3 mm | Design flexibility, supports not required | 395 x 500 x 395 mm | 100μm | 0.5 mm |

| MJF | 3 | ± 0.3% with a lower limit on ± 0.3 | Design flexibility, supports not required | 380 x 285 x 380 mm | 80μm | 0.5 mm |

| SLM | 5 | ± 0.2% with a lower limit of ± 0.127 mm | Metal parts | 320x320x400mm | 200μm | 1 mm |

3D Printing Technologies

SLS 3D Printing FAQs

SLS is a great solution for the rapid prototyping of functional polymers because it offers a very high degree of design freedom and high accuracy. And unlike FDM or SLA 3D printing techniques, it produces parts with consistent mechanical properties. This means it can be leveraged to produce parts that are very close to end-use part quality, so you can rely on the technology for concept to trial models.

Its versatility makes SLS 3D printing an ideal alternative to injection molding for low-production runs. SLS can be used to manufacture parts with complex shapes and geometries, and with a wide variety of finishes and lead times.