- Capabilities

-

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

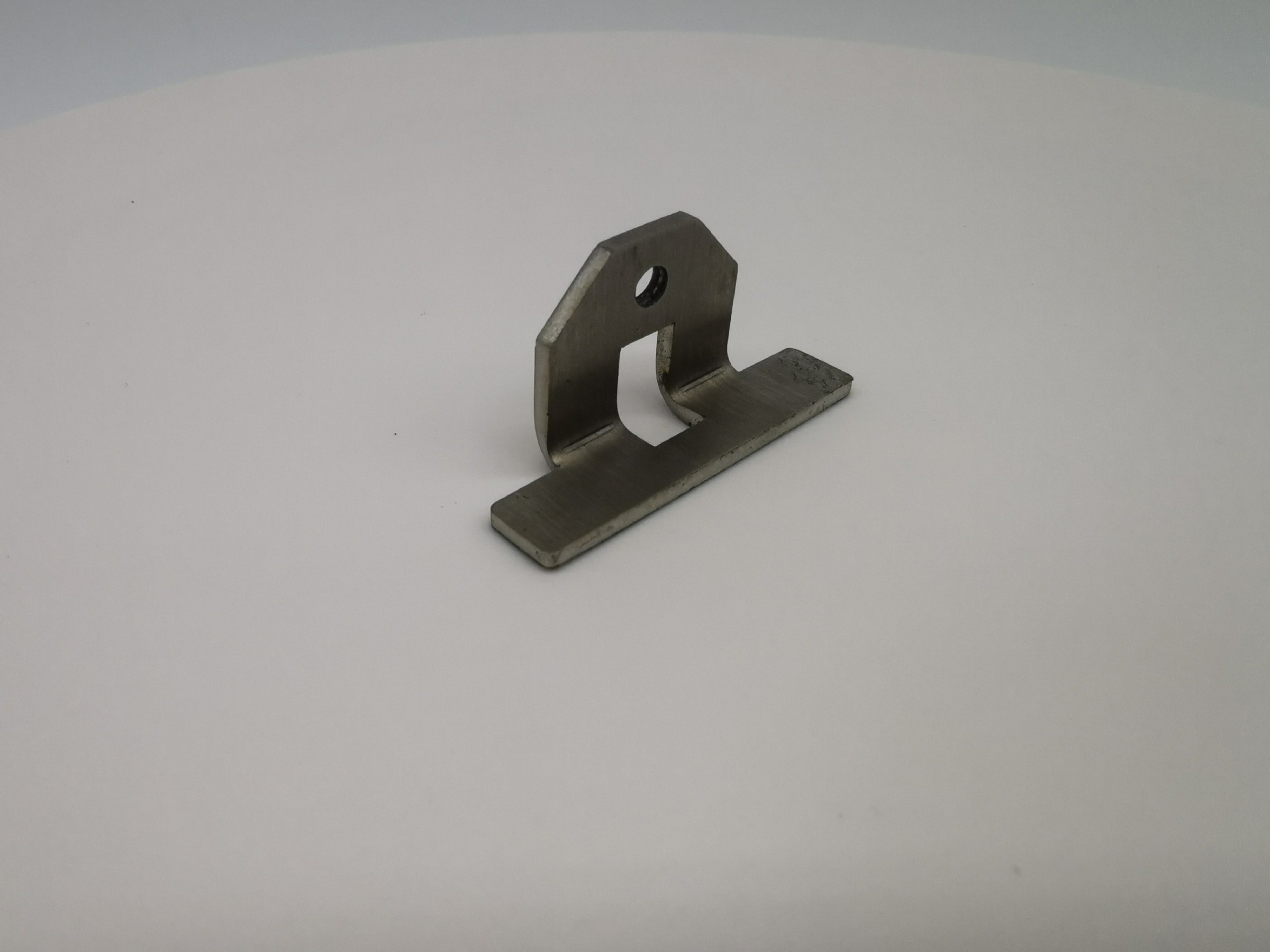

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

Sheet Metal Fabrication Materials

Hot Rolled Steel Sheet Metal Fabrication

Hot rolling is a mill process where steel is rolled at a high temperature, easier to make, shape and form.

All uploads are secure and confidential

Hot Rolled Steel Sheet Metal Fabrication

Hot rolled steel, HRS short, is produced when steel is processed by a series of roll presses at temperatures over 1700 ° F. The procedure creates steel that is easily developed or shaped right into large pieces and is the best-made use of where tolerances aren’t as important.

Q235 and Q345 are 16 Mn steel quality with excellent formability and weldability in residential or commercial properties. It’s commonly utilized for architectural applications and components for a selection of industries.

Q345 offers much better efficiency at low-temperature levels and provides far better steel toughness.

Hot Rolled Steel Sheet Metal Fabrication Surface Finishes

Hot Rolled Steel Sheet Metal Fabrication Advantages & Disadvantages

Advantages

- Good adaptability making it suitable for architectural parts

- Well fit to high manufacturing runs

- Suitable for a range of shapes and types

- The cooling procedure hardens and stabilizes the material which avoids any type of interior stresses

- Reduced price than cold rolled steel

- Good mechanical efficiency in terms of strength

Disadvantages

- The surface area is rougher than cold rolled steel and can have blemishes

- Looser tolerances than cold rolled steel

- Require surface finishing to avoid corrosion

- Available only in thicknesses over 3mm (0.12 inches)

- Less formability than cold rolled steel

- Material mechanical performance fluctuate across a single sheet / batch

- Unstable spring back during CNC bending

Hot Rolled Steel Sheet Metal Fabrication Application

Automotive

Rail tracks, hopper cars, components

Construction

Construction including i-beams, metal buildings, doors, shelving

Vehicle

Vehicle frames, agricultural equipment

Pipe

Water heaters, pipes, tubes

Cross-sections

Cross-sections