- Capabilities

-

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

Home > CNC Machining Materials > Metals > Stainless Steel

CNC Machining Materials

Stainless Steel CNC Machining Services

Stainless steel alloys have high toughness, ductility, wear, and rust resistance. Stainless steel is easy to be welded, machined, and polished.

All uploads are secure and confidential

Stainless Steel CNC Machining

The machining of stainless steel can be challenging because of its hardness. 316 is harder machining than 304.

Stainless steel is low carbon steel but it can resist deterioration. This is the main feature that differs stainless steel from normal steel. All stainless-steel chemical structures consist of at least 10.5% chromium.

Stainless steel is classified into Austenitic, ferritic, martensitic, and duplex based on the crystalline structure.

Austenitic stainless steel, typical 200 and 300 series, is extremely formable, nonmagnetic, and can not be hardened.

Ferritic stainless steels are magnetic and have a better thermal conductivity than austenitic stainless. They can not be solidified by heat treatment.

Martensitic stainless steel, such as quality 416 and 420 can be hardened with multiple techniques of aging or heat treatment.

Duplex stainless steel, also called austenitic-ferritic, is a grade of highly specialized stainless for enhanced rust resistance. Duplex steels are normal in industrial and architectural structuring.

Due to its high strength and hardness, stainless steel CNC machining requires expertise and experience.

Stainless Steel Subtypes

| Ultimate tensile strength | Yield strength | Young’s modulus (modulus of elasticity) | Elongation at break | Corrosion resistance | Magnetism | Weldability | Application | ||

| Stainless Steel 301 | 510 – 590 MPa | 200 – 230 MPa | 200 – 212 GPa | 35 – 46 % | Excellent | Non-magnetic in annealed condition | Good | Rail car structural components Air frame sections Automotive wheel covers Wiper blade clips and holders | Learn More |

| Stainless Steel 303 | 580 – 700 MPa | 205 – 350 MPa | 192 – 200 GPa | 40 – 50 % | Moderate | Non-magnetic | Poor | Aircraft applications including fittings Shafts and spindles Automatic screw machine applications Medical devices with screw threads Drilled or tapped holes Pump and valve parts Architecturalapplications Nuts and bolts | Learn More |

| Stainless Steel 304/304L | 520-600 MPa | 210-250 MPa | 191 – 205 GPa | 43-45 % | Good | No | Excellent | Food handling and precessing equipment Food processing Architectural panelling Sanitary ware and troughs Tubing | Learn More |

| Stainless Steel 316/316L | 480 – 600 MPa | 170 – 230 MPa | 190 – 205 GPa | 38-55 % | Excellent | Non-magnetic | Excellent | Chemical and petrochemical industry Food processing Pharmaceuticalequipment Medical devices Potable water Wastewater treatment Marine applications | Learn More |

| Stainless Steel 416 | 440 – 580 MPa | 275 – 345 MPa | 200 GPa | 7 – 25 % | Moderate | Magnetic | Poor | Valves Pump & motor shafts Washing machine components Gears & bolts Nuts & studs Automatic screw-machined components | Learn More |

| Stainless Steel 420 | 485-750 MPa | 275-380 MPa | 190 – 205 GPa | 15 – 20 % | Moderate | Magnetic | Good | Shear blades Needle valves Surgical equipment | Learn More |

| Stainless Steel 430 | 450 – 500 MPa | 200 – 280 MPa | 200 GPa | 20 – 24 % | Good | Magnetic | Good | Low cost sinks Refrigerators Stove element supports Scientific apparatus Fasteners Flue linings | Learn More |

| Stainless Steel 440C | 560 – 800 MPa | 340 – 430 MPa | 204 – 215 GPa | 14 – 18 % | Moderate | Magnetic | Poor | Gage blocks Ball bearings and races Molds and dies Valve components Measuring instruments | Learn More |

| Stainless Steel 17-4 PH | 790 – 1200 MPa | 520 – 860 MPa | 197 – 207 GPa | 3 – 16 % | Excellent | Magnetic | Moderate | Aerospace applications Base plates Chemical processing equipment Oil and petroleum refining equipment Nuclear components | Learn More |

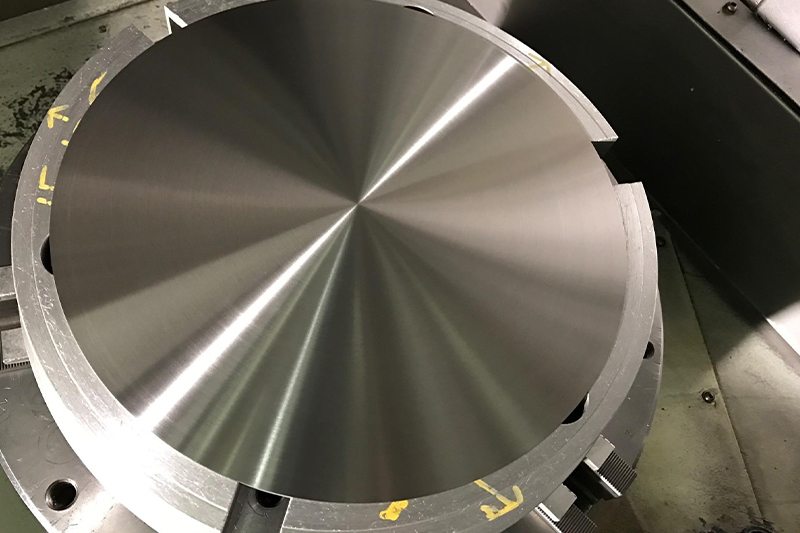

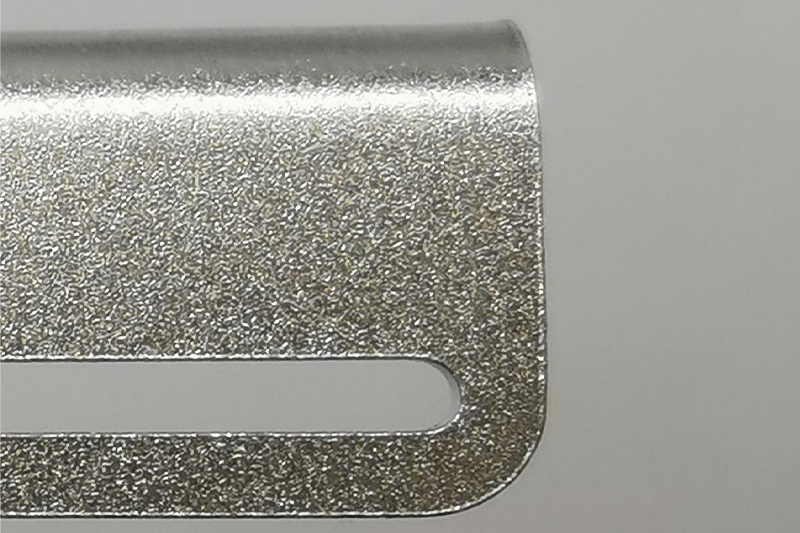

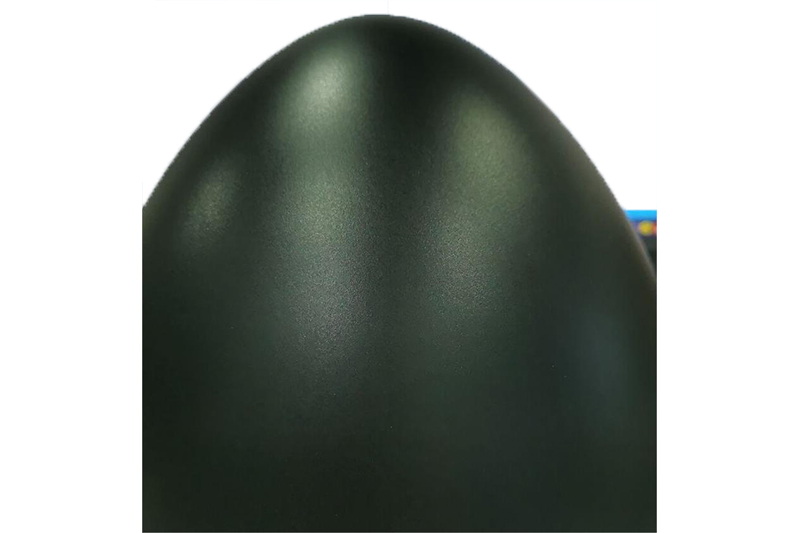

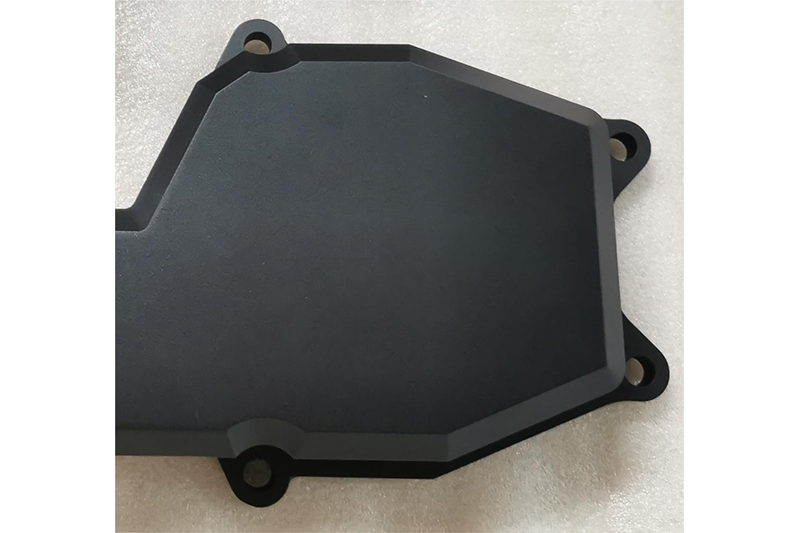

Stainless Steel CNC Machining Surface Finishes

Cost-saving Design Tips

To reduce the cost of stainless steel alloys, below are some design tips:

1.Choose the right alloy

Not all stainless steels are equal in price. Make sure that the picked material is fit for the application. These metals are usually optimal in harsh environments yet not all are resistant to the exact same chemicals.

2.Machinability

Some stainless steels are much more machinable than others. When only light deterioration resistance is required, take into consideration making use of free-machining stainless steel to minimize machining prices.

FAQs

The 300 series family (303, 304, etc.) is austenitic stainless steel. Austenitic stainless grades exhibit high corrosion resistance and strength across wide temperature ranges. They are not heat-treatable except by cold working and are generally non-magnetic.

400 series stainless steels are in the martensitic family. Due to their higher carbon content, martensitic steels are extremely strong and tough but more susceptible to corrosion in specific environments. They can be heat-treated to increase their hardness greatly and are magnetic.

303 stainless steel is the easiest to machine. It maintains good corrosion resistance for industrial machining parts. 303 stainless steel is easily modified, making it ideal for a variety of parts, such as screws, nuts, bolts, gears & shafts.

Thin walls require extra care when CNC machining stainless steel. The absolute minimum thickness is 0.5mm for metals. To minimize costs and machining time, it’s recommended to increase the thickness of thin walls to at least 0.8mm. Unless weight is a determining factor thicker walls are more stable and less costly. Thin features are susceptible to vibration, creating extra complexity and requiring considerably more time in machining operations.

Yes, stainless steels tend to be one of the most difficult metals to work with in CNC machining. Stainless steel gets harder over time, instead of wearing, which combined with the high-heat generation in machining stainless steel, can contribute to tool failure. Getting speeds and feeds right as well as proper tooling is key.