- Capabilities

-

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

Home > CNC Machining Materials > Plastics > HIPS

CNC Machining Materials

HIPS CNC Machining

HIPS is a thermoplastic known for its exceptional impact resistance, lightweight composition, ease of fabrication, and good chemical resistance.

All uploads are secure and confidential

HIPS CNC Machining

High-impact polystyrene, HIPS for short, is a durable thermoplastic suitable for applications requiring toughness, recognized for its exceptional impact resistance. Its lightweight nature makes it advantageous in scenarios where weight considerations are paramount. HIPS is also known for its ease of fabrication, lending itself to processes such as injection molding, extrusion, and thermoforming. Additionally, it exhibits good chemical resistance, enhancing its versatility in different environmental conditions.

HIPS finds applications across a diverse range of industries. In the packaging sector, it is commonly employed for the production of food packaging trays, disposable cups, and protective packaging. The ease of fabrication makes HIPS a popular choice for creating point-of-sale displays, signage, and various visual merchandising materials. Its use extends to model making and prototyping, where its workability allows for easy cutting, shaping, and bonding. Consumer goods, including toys, cosmetic packaging, and office supplies, often incorporate HIPS. Furthermore, it can be found in construction applications such as interior wall cladding.

HIPS CNC Machining Surface Finishes

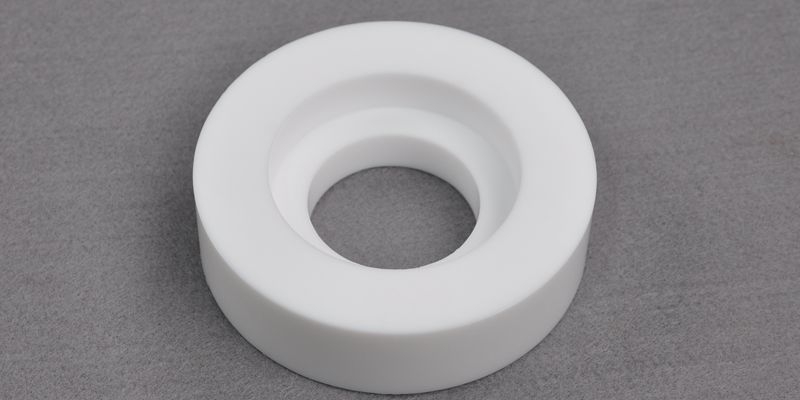

HIPS CNC Machining Gallery

Cost-saving Design Tips

To reduce costs, limit part setups numbers, inspection dimensions or tight tolerances numbers, and deep pockets with small radii.

HIPS CNC Machining FAQs

Common alloys include 4140 and4340, known for their strength and toughness.