- Capabilities

-

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

Vapor Polishing Steps - A Step By Step Guide

Updated: December 08, 2023

Table of Contents

- 1. What is Vapor Polishing?

- 2. The Vapor Polishing Steps

- 3. Advantages of Vapor Polishing

- 4. Factors Affecting Vapor Polishing Quality

- 5. What Plastics Can Be Vapor Polished?

- 6. What Solvent Is Used?

- 7. Vapor Polishing Effects on Plastics

- 8. Vapor Polishing vs. Manual Polishing

- 9. Industries and Applications

- 10. ECOREPRAP’s Vapor Polishing Services

- 11. FAQs

Vapor polishing is widely used for CNC-machined acrylic, CNC machined Polycarbonate, and 3d printed parts to improve transparency and surface roughness. It is a surface treatment for plastic at a microscopic level. This post will help you get all the information you want to know about vapor polishing steps.

1. What is Vapor Polishing?

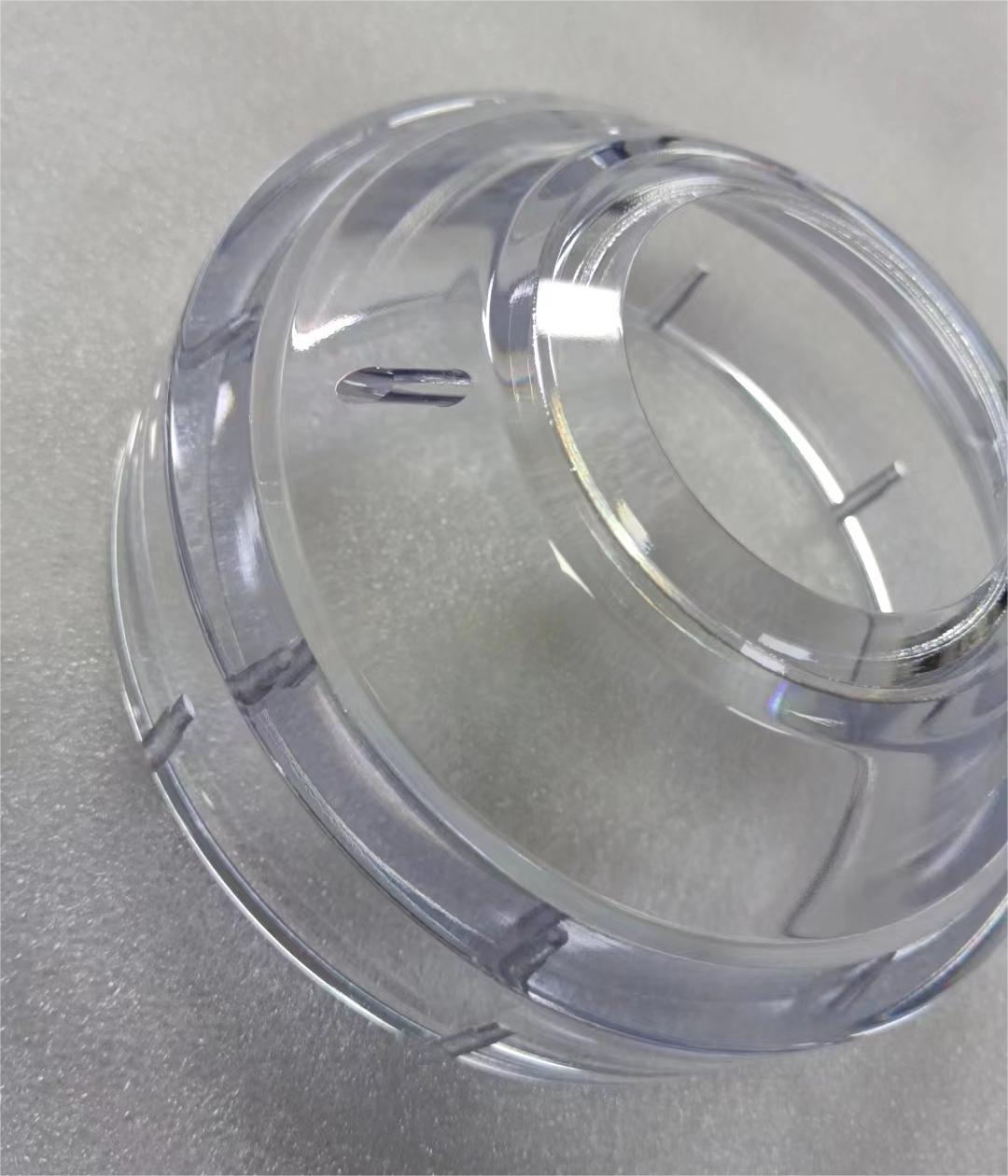

Vapor polishing is a specialized technique for polishing various plastics, such as acrylic (PMMA), PC(polycarbonate), PE, and 3d printed parts. A solvent is converted into a vapor and applied to the surface of the part or product. This process is especially effective for polishing small and intricate parts, including delicate internal features like threads, channels, apertures, and inspection areas that are hard to polish manually.

For different plastics, the solvent may differ. Weldon 4 solvent is usually used to improve the surface finishes for vapor polishing polycarbonate.

2. Vapor Polishing Steps

Generally speaking, vapor polishing is a technique employed for smoothing out specific kinds of plastic resin materials at the microscopic level. Due to its reactivity with plastic, this process uses a heated Weld0n 4 solvent in its gaseous state. The vapor from the heated solvent is applied to the workpiece’s surface, melting the plastic and filling in microscopic voids and scratches. When the gas is no longer present, the plastic quickly solidifies, resulting in a smoother and more pristine surface.

Before vapor polishing starts, the workpiece undergoes sanding using 100 and 500-grit sandpaper to reduce deeper marks and ensure comprehensive vapor reach. Sanding and manually polishing the surface is a must before vapor polishing steps.

The main vapor polishing steps are as follows.

Step 1: Clean the workpiece

To ensure vapor polishing performance, we need to clean the workpiece effectively. Start by removing the visible debris and contaminants on the workpiece surface with a soft brush or compressed air. Then, wash them with pure water or a mild detergent to remove the remaining dirt, grease, or oil. Use a soft cloth or sponge to dry the surface gently. Rinse the workpiece thoroughly with clean water 2 or 3 times more to remove any soap residue. Leave the workpiece in the air to dry completely before proceeding with vapor polishing.

Step 2: Heat the Solvent for Vaopr Generation

Find a clean, heat-resistant container to hold Weldon 4 solvent. A kettle will work. But make sure the container is clean and free from any contaminants. Pour the Weldon 4 solvent in and warm the container. When reaching a specific temperature, the Weldon 4 solvent will become gas and come out. Maintain the heating temperature.

Step 3: Vapor Exposure

The solvent vapor will interact with the plastic workpiece surface. It will soften and partially dissolve the surface, smoothing out the imperfections and irregularities. The exposure to the solvent vapor is crucial.

Step 4: Recondensation

The solvent vapor goes back and forth onto the plastic surface, removing any remaining imperfections and leaving a smooth and polished finish. The recondensation is essential for ensuring uniformity and consistency in the final polished surface.

Step 5: Dry the Workpiece

Wash the polished workpiece with clean water, put it in a well-ventilated area, and dry it naturally.

Step 6: Final Cleaning and Inspection

Once the vapor polishing is complete, clean the plastic surface thoroughly to remove any remaining polishing compound. Inspect the surface for any missed scratches or imperfections.

3. Advantages of Vapor Polishing

Vapor polishing has many applications and benefits; the three key benefits are listed below.

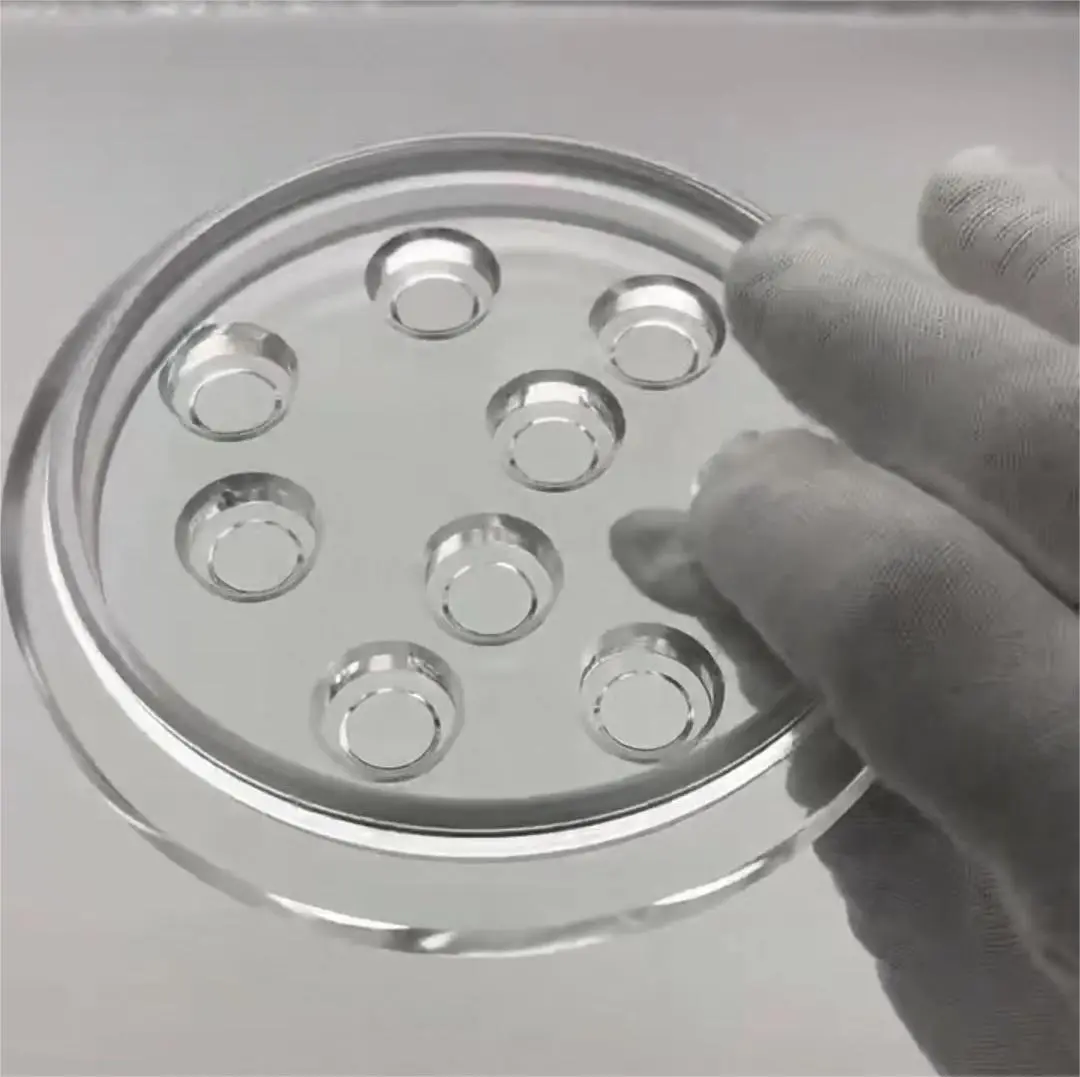

3.1 Light Transmission & Optical Clarity

One of the primary benefits of using vapor polish treatment is the significant improvement in light transmission capability and optical clarity of the polished parts. It allows for an unobstructed passage of light, making it an ideal process for parts used in light emission applications or where clear visibility is necessary.

This makes it a go-to method for improving fluid flow visibility, particularly for medical equipment, and a preferred technique for creating parts for displays, artwork, electrical components, and other items requiring high clarity and shine.

3.2 Enhanced Product Aesthetics

Additionally, vapor polish dramatically enhances the aesthetics of a product, providing it with an excellent water-clear finish and a high gloss. This aesthetic improvement contributes to the overall increase in the product’s value.

3.3 Surface Enhancement

Vapor polishing does not only improve the looks of a product but also enhances its surface. Compared to conventional post-processing surface finishes like sanding, it eliminates all surface irregularities and markings. This is a great advantage, especially for smoothing 3D printed parts with transparent SLA resin and CNC machined parts in acrylic and PC.

4. Factors Affecting Vapor Polishing Quality

The effectiveness can be influenced by numerous factors.

4.1 Type of Plastic

Different types of plastics respond differently to vapor polishing Certain plastics, particularly acrylics (PMMA) and PC(polycarbonates), are well-suited to vapor polishing.

4.2 Surface Condition

The initial condition of the plastic surface, including any scratches, imperfections, or machining marks, can affect the overall results2. Therefore, the surfaces should be adequately cleaned and sanded to reduce deeper scratches and ensure even vapor reach.

4.3 Object Geometry

The shape and geometry of the plastic object being polished influence the effectiveness of vapor polishing. Complex shapes require careful alignment to ensure uniform polishing across all surfaces.

4.4 Type of Solvent

The solvent’s type plays a paramount role in the process, as its reactivity with specific materials affects the results. For example, Weldon 4 solvent is known for its high reactivity with polycarbonates.

4.5 Solvent Temperature and Concentration

The solvent temperature impacts the rate at which the plastic softens and the effectiveness of the polishing process. Further, the concentration of the solvent vapor in the polishing chamber also has a significant bearing on the effectiveness of the process.

4.5 Exposure Time

The duration of exposure to the vaporized solvent plays a significant role in the polishing process. Adequate exposure time should be ensured to prevent an incomplete polish or damage to the plastic.

4.6 Ventilation and Airflow

Proper ventilation is necessary to ensure that the solvent vapors do not linger around the plastic surface. Adequate airflow helps in the even distribution of solvent and prevents uneven polishing.

4.7 Handling and Placement

Proper handling and placement of the plastic objects within the polishing chamber are crucial. Assurance that objects are positioned correctly and securely can contribute to uniform and consistent results.

4.8 Quality of Equipment

The quality and design of the vapor polishing equipment, including the polishing chamber and heating system, impact the overall effectiveness of the process. It’s essential to use well-designed equipment to ensure better control over polishing conditions.

5. What Plastics Can Be Vapor Polished?

It is typically effective on thermoplastic materials, particularly those that have good solubility in specific solvents. Many plastics can be vapor polished, for example, PMMA(acrylic), Polycarbonate (PC), Polystyrene (PS), Polyethylene Terephthalate Glycol (PETG), Polyethylene (PE), Polypropylene(PP), Polyvinyl Chloride (PVC), Acrylonitrile Butadiene Styrene(ABS ), Polysulfones(PSF), Polyetherimide (PEI), COC and COP.

Based on our experience, the following three materials have the best vapor polishing results.

5.1 PMMA(acrylic)

5.3 3D printed parts with transparent SLA resin

Read our post about our post A Complete on Acrylic Polishing to learn how to get a highly transparent acrylic CNC machined part.

6. What Solvent Is Used for Vapor Polishing

We call know different plastics have different solubilities and responses to different chemicals. So, the solvent also differs; for PMMA and PC CNC machining parts, dichloromethane, chloroform, or a mixture of various solvents can be used to perform the vapor polishing. Weldon 4 is primarily composed of Methylene Chloride (Dichloromethane, DCM). This organic solvent is widely favored for its vapor polishing application in PMMA and PC.

7. Vapor Polishing Effects on Plastics

Vapor polishing has several effects on plastic surfaces. The below information is based on one research article Impact of Vapor Polishing on surface quality and mechanical properties of extruded ABS by Brigham Young University. Let’s discuss one by one.

7.1 Dimensional Changes

Vapor polishing has a very limited effect on the dimensions.

7.2 Surface Roughness

The key motivation for using vapor polishing is to reduce the roughness. This is also the main reason why vapor polishing can improve transparency and surface finish.

7.3 Mechanical Properties

By sanding and vapor polishing, it will not have significant differences in mechanical properties.

7.4 Hermeticity

Vapor polishing can have a profound effect on alleviating surface porosity and achieving a gross hermetic seal for components.

8. Vapor Polishing vs. Manual Polishing: How to Make a Right Choice?

When choosing between these two treatments for your surface finishing needs, weighing each method’s pros and cons is essential. Here, we highlight the main aspects of vapor polishing vs. manual polishing to help you make an informed decision.

Manual Polishing Pros:

Ease of Accessibility: The equipment needed for manual polishing is readily available, making it a convenient option.

Health Impact: The process does not negatively impact health; the only concern is the dust produced during polishing. This can be mitigated with proper safety measures, such as using a nose mask and other safety gear.

Manual Polishing Cons:

Labor and Time-Intensive: Manual polishing can be laborious, and achieving a glossy finish or excellent optical clarity can take significant time.

Uniformity: It is challenging to achieve a uniform finish on parts with complex geometry using manual polishing techniques.

Vapor Polishing Pros:

Efficiency: It is an efficient and quick surface finishing method.

Consistent Finish: Parts produced via vapor polishing have a consistently shiny finish and excellent optical clarity.

Minimal Material Removal: The process has minimal material removal, which helps save costs on the material used.

Application: It suits medical devices, equipment, and intricate features like channels, undercuts, apertures, and threads.

Vapor Polishing Cons:

Material Limitations: It is not ideal for use on every plastic material.

Cost of Set-Up: The process often requires expensive materials and equipment to run optimally.

Pre-Processing Requirements: Some materials that can undergo vapor polishing may still require annealing before polishing, which increases the overall production cost.

Manual polishing is necessary for CNC-machined PMMA and PC parts before the vapor polish treatment.

Considering the advantages and disadvantages of each method, your choice should be based on your project requirements, such as material type, desired surface finish, component complexity, and budget constraints.

9. Industries and Applications of Vapor Polishing

Vapor polishing is mainly to create smooth, glossy surfaces and improve optical clarity. It has been widely adopted across various sectors. Let us gain insights into the diverse advantages vapor polishing offers.

9.1 Medical Devices and Equipment

For both functional and aesthetic reasons, the medical devices industry cnc machining parts frequently uses this treatment. It provides a high-standard surface finish which is essential for medical equipment, often requiring precision, cleanliness, and optical clarity.

9.2 3D Printing and Prototyping

It is beneficial in the 3D printing industry and prototyping sectors. The process efficiently refines rough surfaces and visible layer lines from printed parts, contributing to a polished and refined appearance.

9.3 Optical Components and Photonics

Used in the manufacturing of lenses, prisms, and light guides, vapor polishing assists in improving the clarity and transparency of optical components for better performance.

9.4 Aerospace, Automotive, and Electronics

For aerospace, automotive, and electronics industries, vapor polish is employed to achieve smooth finishes on small, intricate, or complex parts. It also enhances the visual appeal and functionality of clear or transparent plastic parts, like headlamp lenses, interior displays, or even specific plastic components in aerospace applications.

9.5 Consumer Electronics and Consumer Products

Transparent or translucent plastic components in consumer electronics, such as screens, covers, and housings often undergo vapor polishing to achieve a smooth and visually appealing finish.

9.6 Display, Signage, and Lighting

Manufacturers of displays, signage, and illuminated panels commonly use this chemical surface treatment to improve the clarity and appearance of plastic surfaces, ensuring optimal visibility.

9.7 Food Processing

Utilized to improve the smoothness and shine of product parts that come in contact with food. Beyond the aesthetic benefits, it also improves product cleanability, thus reducing the growth of harmful microorganisms.

10. ECOREPRAP’s Vapor Polishing Services

With well-trained workers, ECOREPRAP offers excellent CNC machined acrylic and PC parts . Contact us for your project now!

11. FAQs

10.1 Can you vapor polish acrylic?

Yes, the acrylic parts we machine have have a super performance.

10.2 What is acetone polishing?

Acetone can be used as a vapor polishing solvent for ABS.

10.3 Is sanding required before vapor polish?

For CNC machined parts, sanding is always necessary. The sanding grit is about 1500.

10.4 Is the process dangerous?

This process can be potentially hazardous for untrained individuals due to the solvents’ toxicity. Therefore, it is strongly advised that only trained professionals carry out these procedures, which should take place within a controlled chamber. The professionals are required to wear breathing respirators for safety.

10.5 Can anyone perform this procedure?

For safety reasons, it is also recommended that professionals familiar with handling solvents and safety protocols perform vapor polishing.

10.6 How long does it take?

Generally speaking, it is a relatively quick process. Once the vapor is applied to the plastic, the material becomes apparent within a few seconds.

10.7 Why did the acrylic parts craze during vapor polishing?

Due to stress generation, cracks might occur in the g process of PMMA (Acrylic) and PC (Polycarbonate). During this process, the rapid evaporation of the solvent from the surface of the part can cause excessive cooling and consequent thermal stress.

Additionally, internal stress might be induced when the material particles expand at high temperatures and then contract while cooling. These stresses can lead to micro-cracks in the plastic material, sometimes called “crazing.”

One way to address this issue is through annealing the treated parts, which involves precise heating and cooling to eliminate the stresses within the plastic. This not only can prevent crazing but may also enhance the dimensional stability of the parts, improve the integrity of the product, reduce shrinkage and swelling, and improve the chemical resistance of the parts.

Other factors that may cause cracks are solvent exposure, poor ventilation, aggressive solvents, unstable temperatures, and plastic impurities. Tests on samples can help control exposure time, solvent concentration, and ventilation to reduce cracks.

Let's get your projects started, together!

Get custom parts machined in high quality, delivery on time.