- Capabilities

-

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

Surface Finishes

Brushing Services

Brushing produces a smooth surface finish, improving the high quality of your part after machining.

All your designs are secure and confidential

Brushing

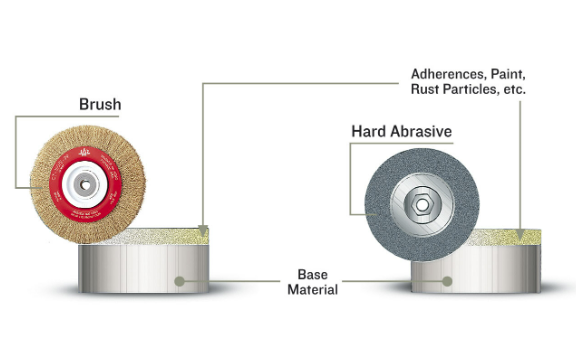

The brushing process is a mechanical surface-completing strategy that includes using abrasive brushes, typically made from cable or nylon, to eliminate surface area blemishes and develop a textured or matte finish on steel surfaces. It is commonly made used in metalworking to improve the appearance and appearance of parts, get rid of burrs, and develop a consistent, direct grain pattern. Brushing can be put on a variety of steels, consisting of stainless steel and lightweight aluminum, and is commonly used in applications where aesthetic appeals and cleanliness are crucial.

| Applicable Materials | Cosmetic Availability | Visual Appearance |

| Steel,Aluminum, Copper | On request | Smooth, glossy finish |

Brushing Parts

Brushing Process

- Preparation: The part’s surface is cleaned and prepared to ensure it’s free from contaminants or oxidation.

- Brushing: The abrasive brush is used to remove imperfections and create the desired brushed pattern. The brush can be applied manually or through automated machinery.

- Grain Direction: The brushing is done in a specific direction to achieve the desired linear grain pattern.

- Final Inspection: The finished part is inspected to ensure it meets the required quality and appearance standards.

Brushing Design Considerations

- Consider the overall design and aesthetics to determine whether horizontal, vertical, or diagonal brushing best complements the intended look.

- There are different types of brushes, such as wire, abrasive, or nylon brushes. The choice of brush material and stiffness impacts the texture and finish.

- Determine the desired level of texture on the metal surface. Finer brushes create a smoother finish, while coarser brushes can introduce a more pronounced texture.

- Thicker materials may require adjustments in brushing parameters to ensure an even finish without compromising the structural integrity of the metal.

FAQs

Brushing is a mechanical surface finishing process that uses abrasive brushes to create a textured or matte finish on metal parts.

Brushing enhances the appearance, texture, and cleanliness of metal parts, making it popular for decorative and functional purposes.

Brushing is suitable for various metals, including stainless steel, aluminum, and brass.

Yes, brushing can be used on precision components, as it has minimal impact on part dimensions.

Brushing can produce a textured finish with varying levels of roughness, depending on the abrasive used.

Yes, brushing effectively removes burrs, sharp edges, and minor surface imperfections.

Yes, brushing can be applied to parts with complex shapes and intricate features.

No, brushing primarily enhances appearance and texture, not electrical properties.