Polyurethane and Silicone Vacuum Casting Services

Trusted vacuum casting solution for prototypes and low-volume production components at competitive prices.

- From 1 to 25 parts per mold

- Production grade quality

- 24/7 engineering support

- Global delivery

What is vacuum casting?

Vacuum casting or urethane casting or polyurethane and silicone vacuum spreading is a technology that incorporates silicone molds and a 3D printed master pattern to develop short-run, rigid parts with production-level top quality. The process solidifies polycarbonate polyurethane inside silicon or epoxy molds. The outcome is the vacuum cleaner spreading parts with the same shapes as the initial master models. The final measurements of the vacuum cleaner casting components will certainly depend upon the master version, part geometry, and the product chosen.

Vacuum Casting Advantages

Production Quality at Low Volumes

This process is a fast, cost-efficient method to generate 10-200 units with production-level quality. Generally, each silicone mold will certainly create 20 spreadings.

Complex Elastomeric Parts

Urethane spreading is excellent for prototyping elastomeric parts such as complex gaskets and over molds on rigid components.

High Level of Detail

Urethane spreading enables almost limitless intricacy, consisting of sharp inner edges unattainable with CNC machining, and styles without draft or consistent wall-thickness that can not be injection built.

Unmatched Lead Time

Up to 50 functional urethane components can be created in 10 to 15 days when you select vacuum cleaner casting.

Flexible Color Options

Integrate various shade pigments to accomplish the intended results on your finished products.

Wide Selection Materials

Casting materials range from soft and adaptable to rigid and impact-resistant, along with colored and clear.

Excellent Surface Finish

Urethane casting can supply much better surface structures compared with CNC prototyping or 3D printing.

Low Cost Molds

The silicone molds are fairly low-cost tooling compared to injection molds and are simple to make changes.

Vacuum Casting Materials

ABS-Like

Functional polyurethane plastic resin that is comparable to ABS thermoplastic. Difficult, rigid, and impact-resistant, it is suitable for various products.

All colors; precise pantone color matching available

Shore D 78-82

General purpose, product enclosures

PMMA-Like

PMMA-Like, acrylic-like, is a rigid, clear polyurethane plastic that simulates acrylic (PMMA). This product is excellent for transparent applications such as light pipes.

Clear Hardness: Shore D 87

Light pipes, see-through applications

PC-Like

Stiff, high-impact, and clear material with a wide variety of uses. Easy to device and finish, simulating polycarbonate.

Clear and various colors

Shore D 82-86

Light diffusers, signs, skylights, visors

PP-Like

Hard, adaptable, and abrasion-resistant urethane with inexpensive and polypropylene-like ductility.

Black or natural only

Enclosures, food containers, medical applications, toys

Rubber-Like

Polyurethane plastic resin, simulating rubber-like materials like TPU, TPE and silicone rubber.

All colors and precise Pantone color matchings

Shore A 20 to 90

Wearables, overmolds, gaskets

Silicon

Silicone is not just used for making devices in casting, however, it is also an exceptional material for components.

All colors and precise Pantone color matchings

medical devices, surgical models, kitchen accessories

Vacuum Casting Application

Low-Volume Production

Urethane cast parts are best for low-quantity production-- when volumes do not validate investment in shot mold tooling- in addition to for first-run manufacturing components, which can be completed weeks before manufacturing tooling is ready.

Advanced Prototyping

The urethane spreading process and fairly economical tooling make it simple and affordable to make any kind of essential style changes. Additionally, various products can be made use of with the same mold, making it possible to evaluate designs with a selection of materials.

Market Testing

End-user functionality and a top-notch coating make urethane cast parts perfect for consumer screening, individual assessment, and principle designs. Utilizing the parts urethane process indicates that changes can be included swiftly for either further testing or market launch.

Vacuum Casting Process

Step 1: The Master Pattern

Patterns are 3D solids of your CAD layouts. They are usually made either by CNC machining or some form of 3D printing such as SLA. Note, nonetheless, that a pattern made from 3D printing will certainly not be quite the like the CNC counterpart, since the later procedure makes use of rounded cutting tools that can not make very limited span edges.

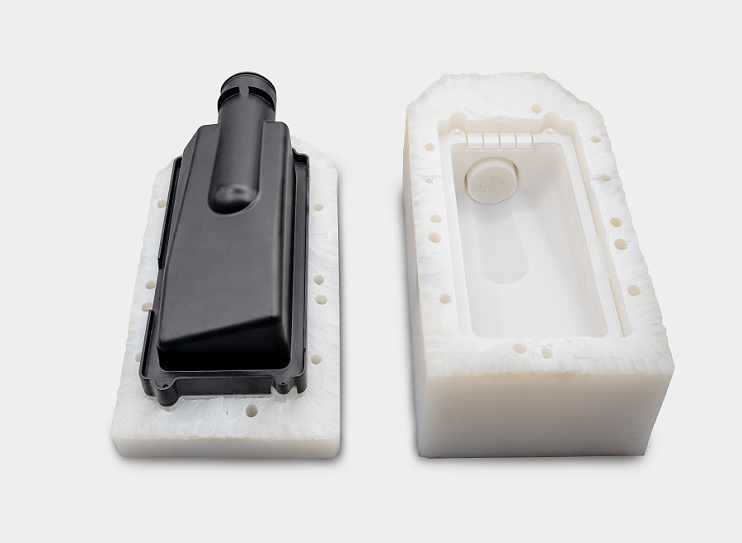

Step 2:Making the Molds

Casting molds are made from liquid silicone. This silicone is poured around the master pattern inside of a casting box, and after that permitted to be treated in an oven for 16 hours. As soon as dried out, the mold and mildew are reduced and the master is eliminated, leaving behind an empty cavity in the specific negative shape of the initial.

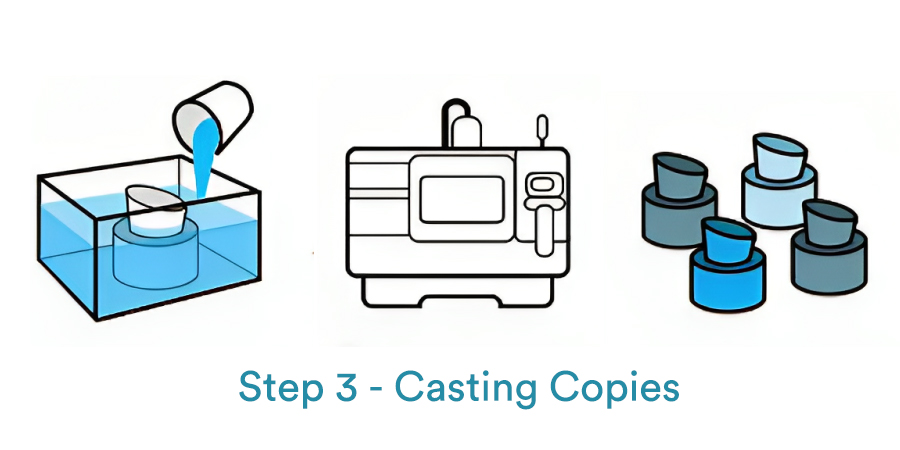

Step 3:Casting Copies

Your selection of casting resins can currently be poured into the empty cavity to create an extremely exact copy of the original. It’s also possible to over-mold with 2 or even more products. Silicone molds are typically great for 20 or so duplicates of the master pattern.