- Capabilities

-

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

Home > CNC Machining Materials > Plastics > PEEK

CNC Machining Materials

PEEK CNC Machining

PEEK is high-performance with exceptional mechanical properties and chemicals over a really broad temperature level range.

All uploads are secure and confidential

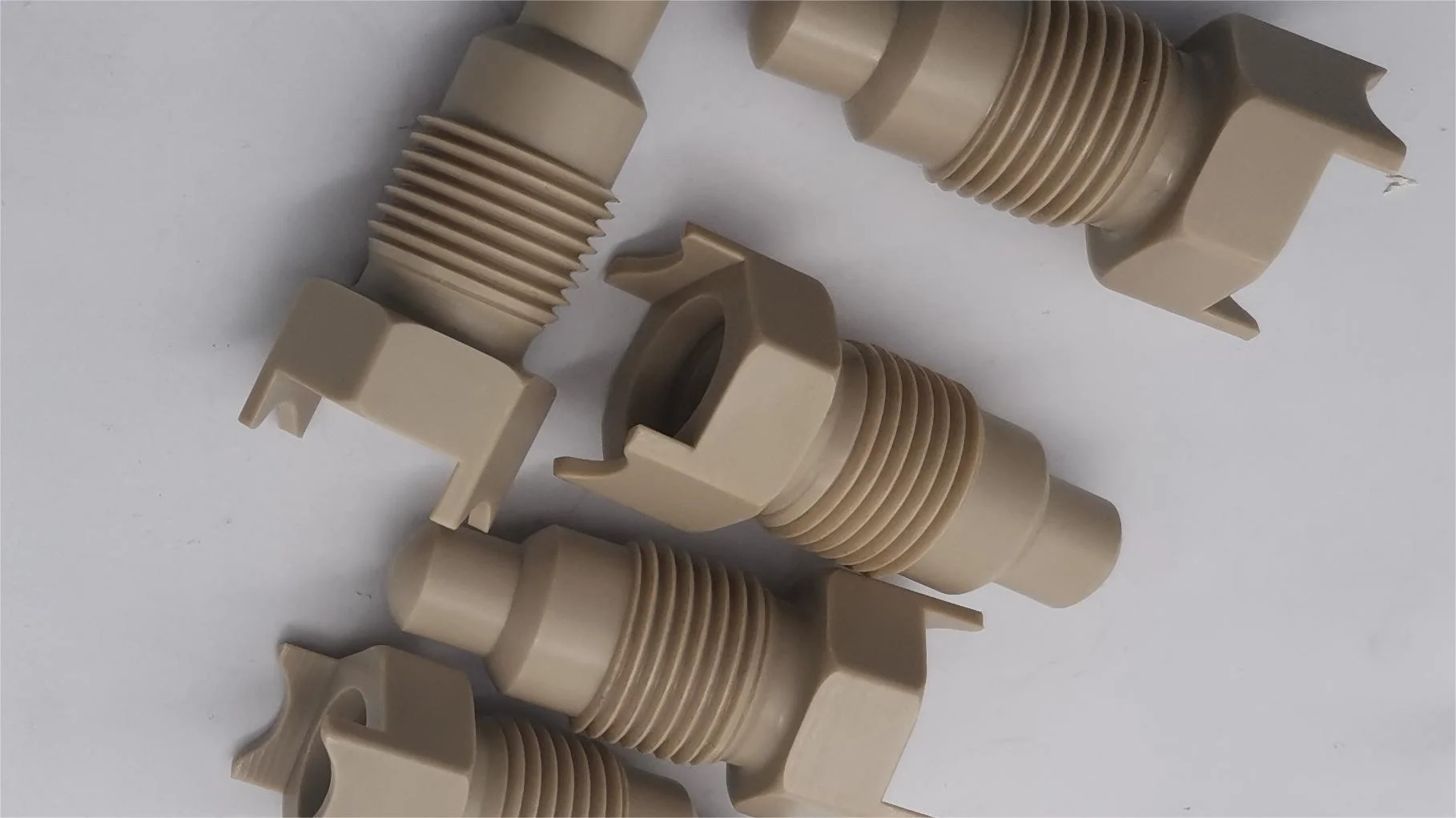

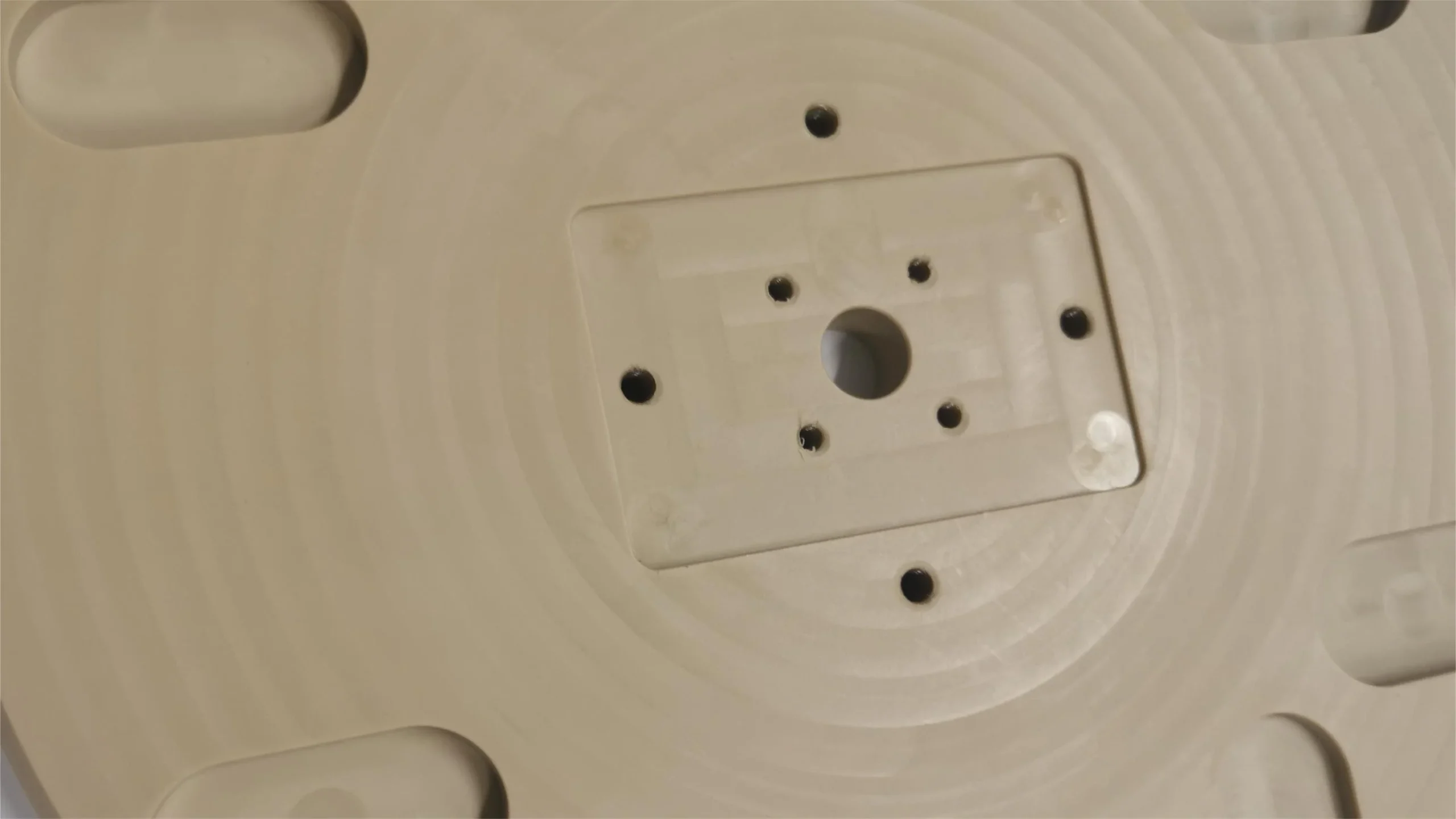

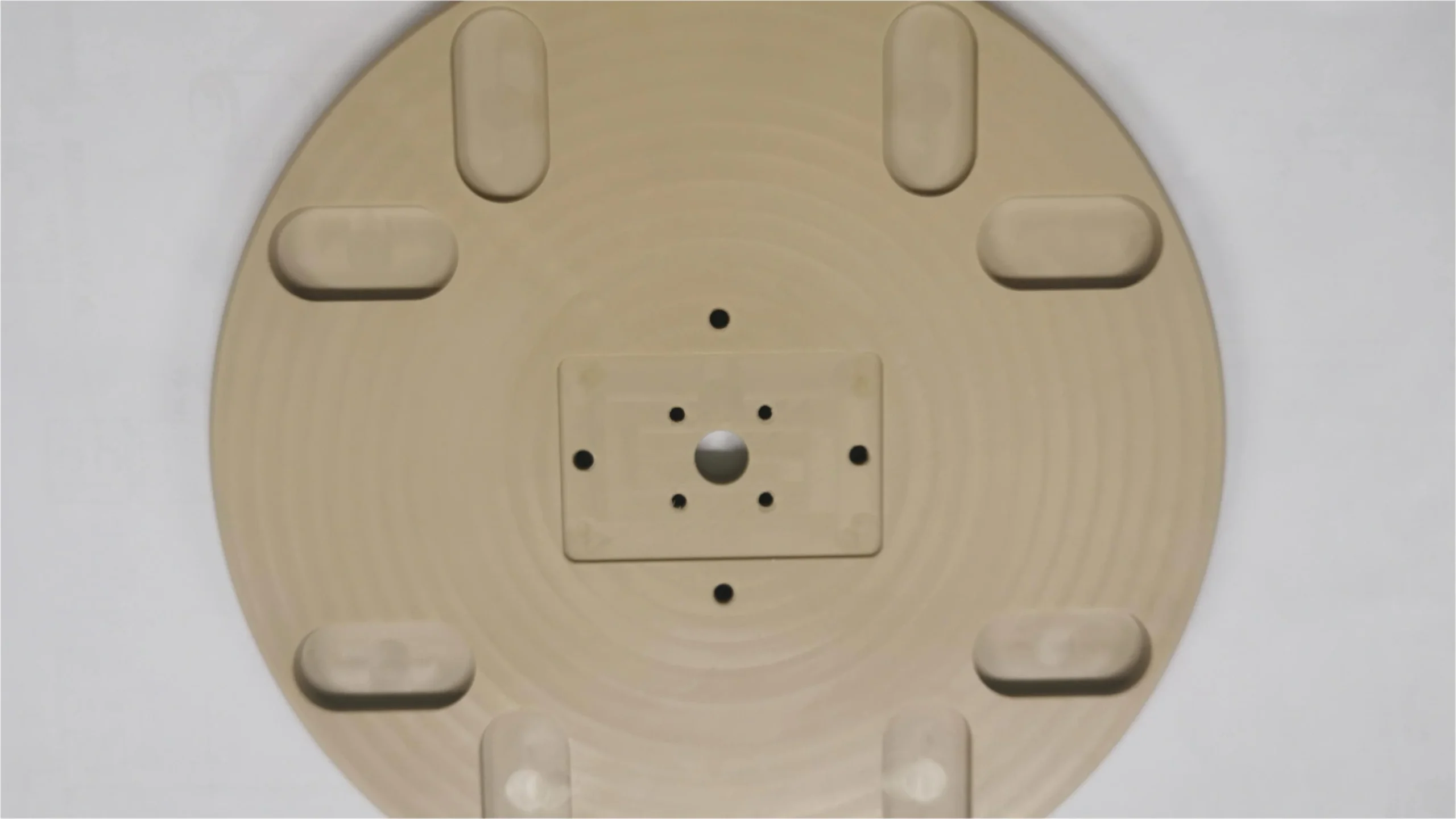

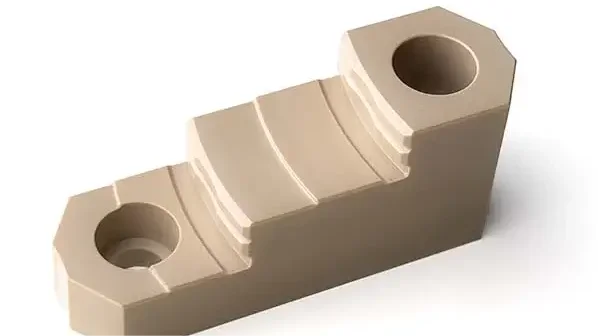

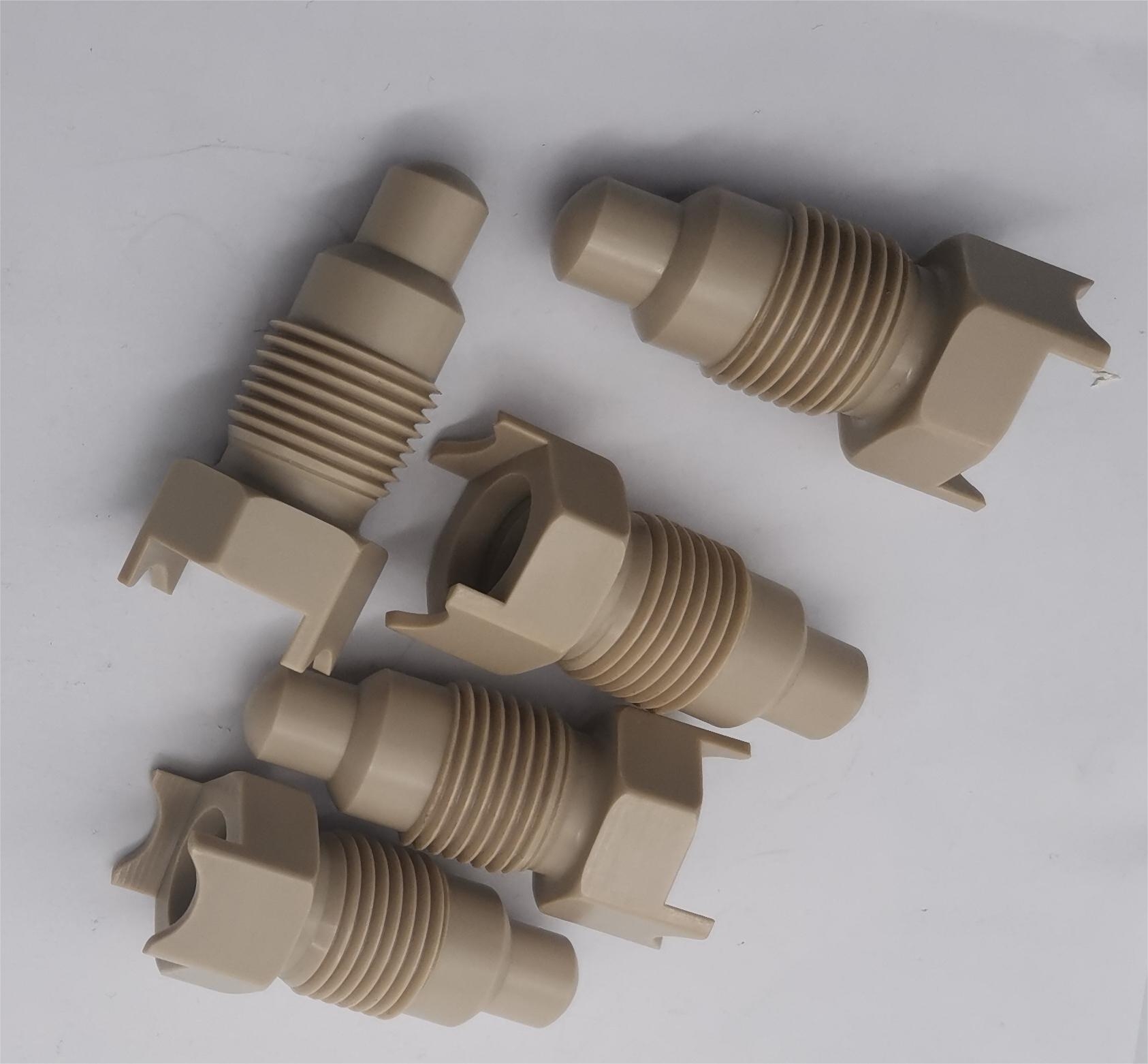

PEEK CNC Machining

PEEK is a semicrystalline thermoplastic that can continuously run at temperatures up to 260 ° C. It is a high-temperature resin utilized in safety-critical industries such as clinical, aerospace, and auto.

The high-performance product supplies excellent chemical and warm resistance, in addition to flame retardancy, and gives outstanding toughness and dimensional stability.

Machining PEEK enables a vast selection of applications that take advantage of this product’s phenomenal residential properties.

PEEK has extremely few disadvantages compared to various other engineering plastics. One advantage that sets CNC machining peek parts apart is its heat resistance. It can run at high temperatures for longer than many other plastics.

Additionally, PEEK is hydrophobic, so it does not conveniently absorb water, and it also outgasses little under vacuum problems. This security is a beautiful possession.

PEEK’s uses consist of clinical applications for short-term implants entirely to aerospace parts subjected to extreme vacuum.

Glass-filled PEEK is a high-performance plastic with excellent rigidity, strength, and durability. Enhancing glass fibers improves its capability to maintain dimensional stability in harsh thermal and chemical settings.

Glass-filled PEEK machined part is typically used in the following markets: airplane, auto, clinical, chemical, semiconductor, and microwave.

Due to the high cost of PEEK, experienced PEEK CNC machining manufacturers typically machine the parts in ABS or POM first for complex custom PEEK parts. They fine-tune the product parameters using these materials before switching to PEEK.

ECOREPRAP is an experienced China CNC machining peek parts manufacturer capable of providing three-axis and five-axis PEEK CNC milled and turned components.

PEEK Properties

| Ultimate tensile strength | Yield strength | Young’s modulus (modulus of elasticity) | Elongation at break | Hardness | UV resistance | Application | ||

| PEEK | 70.3 – 103 MPa | 87 – 95 MPa | 3.76 – 3.95 GPa | 30 – 150 % | 26.1 – 28.5 HV | Good | Bushings & bearings Seals & back-up rings Pump & valve components Medical instrumentation Food processing machinery components | Learn More |

PEEK CNC Machining Surface Finishes

Cost-saving Design Tips

Because of the material’s high cost, overhead costs must be minimized. One method to help manage the expense of CNC machining in PEEK is by requesting annealing during manufacture. This might lower surface area and internal fracturing, which will certainly minimize the scrap rate and lower general prices for the producer.

FAQs

Yes, PEEK (polyetheretherketone) can be machined to a variety of surface finishes. In high-stress/high-temperature applications, PEEK is a great lightweight substitute for most soft metals. It’s resistant to moisture, wear, and chemicals.

PEEK can be 3D printed. Its unique properties allow for the creation of almost any complex geometry, some of which cannot be manufactured using other technologies. The slower the 3D printing speed, the more accurate the end result.

PEEK has a melting point around 341°C (646°F). It has the ability to maintain stiffness and can be used continuously in temperatures up to 260°C (480°F). It can also be used in hot water or steam without compromising physical properties.

PEEK is often used in the following industries: aircraft, automotive, medical, chemical, semiconductor and microwave to manufacture items used in demanding environments, including pumps, bearings, HPLC columns, compressor plate valves, cable insulation, and piston parts.