- Capabilities

-

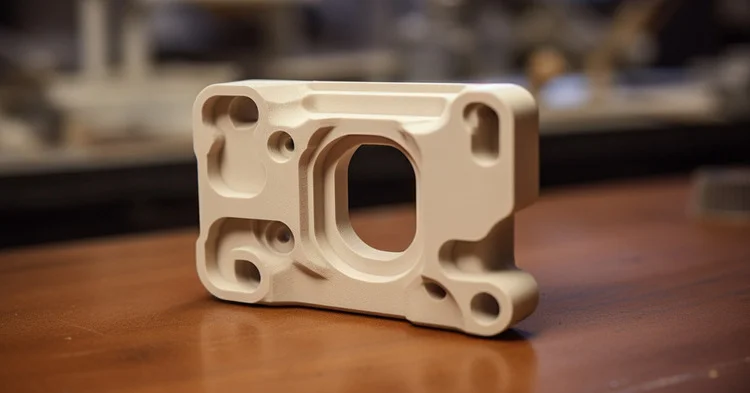

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

Applications of Polyetheretherketone (PEEK) Introduction

Updated: Mar. 23, 2024

Table of Contents

- 1. PEEK Application in Aerospace Industry

- 2. PEEK Application In Automotive Industry

- 3. PEEK Application in Fuel Source Power Systems

- 4. PEEK Application in Semiconductor Industry

- 5. PEEK Application in Petroleum Industry

- 6. PEEK Application in Mechanical Equipment

- 7. PEEK Application in Electronic Industry

- 8. PEEK Application in Deep Sea Exploration Industry

- 9. PEEK Application in Medical industry

PEEK (polyether ether ketone) is a high-performance engineering plastic, its price is usually much higher than the general plastic, to some extent, to limit the scope of its application. Due to its excellent heat resistance, chemical resistance, mechanical properties, abrasion resistance, and high material price, PEEK is mainly used in demanding engineering applications such as high temperature, corrosion resistance, and high strength.

1. Aerospace industry

Lightweight design: PEEK is a relatively lightweight material, so in the aerospace industry it can be used to manufacture structurally lightweight components, helping to reduce the total weight of the vehicle and improve fuel efficiency and performance.

High Temperature Resistance: PEEK has excellent high temperature resistance and is able to maintain its stability and mechanical properties under extreme temperature conditions. Therefore, it is often used in the manufacture of aero-engine components, nozzles, gas turbine parts and other components that need to withstand high temperatures.

Chemical Inertness: PEEK has excellent chemical inertness and is resistant to chemical corrosion and various chemicals. This makes it widely used in the aerospace industry for the manufacture of components that need to resist corrosion.

High Strength and Rigidity: PEEK has excellent mechanical properties, including high strength and rigidity to withstand high loads and vibration, and is used in the aerospace industry for a variety of structural components and connectors.

Abrasion Resistance: PEEK has excellent abrasion resistance and is able to maintain stability in frictional and abrasive environments, making it widely used in lubrication systems, seals and moving parts in aircraft and spacecraft.

2. Automotive industry

Engine Components: PEEK materials are used in the manufacture of engine components such as valves, piston rings, and throttle valves. Due to its high temperature, abrasion and corrosion resistance, PEEK can be used to maintain stability under high temperature, high pressure and high speed engine operating environments, improving engine performance and life.

Transmission system: In the automobile transmission system, PEEK is used as seals for the brake system, clutch friction plates and other parts. Its excellent wear resistance and friction properties help improve the efficiency and durability of the transmission system.

Electrical Components: PEEK is also used in the electrical systems of automobiles for the manufacture of connectors, insulating parts, cable sheathing, etc. PEEK is also used in the electrical systems of automobiles for the manufacture of electrical components. Its excellent insulating properties and chemical resistance make it an ideal material for electrical components.

Interior parts: In automotive interiors, PEEK is used to manufacture a variety of parts, such as instrument panel components, door handles, seat adjusters and so on. Its high strength, rigidity and weather resistance make it the material of choice for interior components.

Other Applications: In addition to the applications mentioned above, PEEK is also commonly used in the manufacture of automotive fuel system components, exhaust system components, suspension parts, etc. PEEK is used in automotive parts manufacturing. Its chemical resistance and abrasion resistance enable it to maintain stability and reliability in these components.

3. Fuel Source Power Systems

Seals and Gaskets: PEEK materials are often used as seals and gaskets in combustion power systems due to their excellent high temperature and chemical resistance. These components need to be able to withstand high temperatures and pressures and have good sealing properties to ensure safe and stable operation of the system.

Valves and Seats: PEEK materials are often used to manufacture valves and seats in combustion power systems due to their good wear and corrosion resistance. These components need to be able to withstand high temperatures, high pressures and high fluid velocities, and the properties of PEEK make it an ideal material choice.

Pipes and connectors: PEEK materials are also commonly used to manufacture pipes and connectors, such as pipe couplings, pipe clamps, etc. PEEK has good corrosion resistance and chemical inertia, and is able to resist the erosion of fuels, lubricating oils and other media, to ensure that the piping system operates stably.

Electrical insulation: in the combustion source power system, PEEK material is also often used as electrical insulation, such as cable sheaths, insulation boards. Its excellent insulating properties and high temperature performance to protect the electrical system from external environmental influences, to ensure the safe operation of the power system.

Sensor parts: PEEK materials are also often used in the manufacture of combustion power systems in the sensor parts, such as sensor housings, seals, etc.. Its high strength, rigidity and abrasion resistance can protect the sensor from external environmental damage, to ensure the accuracy and reliability of the sensor.

4. Semiconductor industry

Packaging and encapsulation materials: PEEK material is often used as a packaging material for semiconductor devices due to its excellent high temperature and chemical resistance. It provides good protection against external environmental damage and maintains stability at high temperatures.

Substrates and Carrier Plates: PEEK is also commonly used to manufacture substrates and carrier plates in semiconductor systems. These components require high strength, rigidity and good insulation to support and protect semiconductor devices, and the properties of PEEK make it an ideal choice.

Mounts and Sockets: PEEK is often used as a manufacturing material for mounts and sockets in semiconductor systems. It provides good mechanical support and connectivity, and can withstand high temperatures and high frequencies.

Insulation and isolation: PEEK is often used as insulation and isolation in semiconductor systems due to its excellent insulating properties. It effectively prevents interference and leakage between circuits, ensuring circuit stability and reliability.

Seals and Gaskets: PEEK materials are also commonly used to make seals and gaskets in semiconductor systems. These components need to be able to provide a good seal to prevent dust, moisture and other contaminants from getting inside the device, and the properties of PEEK allow it to perform this task.

5. Petroleum Industry

Oil well tools and equipment: PEEK materials are often used in the manufacture of oil well tools and equipment, such as drill bits, plugs, pipe connectors, etc., due to their excellent high temperature and chemical resistance. It is able to maintain stability under high temperatures, high pressures and corrosive media, and provides good mechanical properties for a variety of applications in oil well operations and production processes.

Seals and Gaskets: PEEK materials are also commonly used as seals and gaskets in the petroleum industry. These components need to be able to withstand high temperatures and pressures and provide good sealing properties to prevent oil and gas leakage and to prevent contamination of the system from the external environment.

Valves and Seats: In the petroleum industry, PEEK materials are often used to manufacture valves and seats for flow control and fluid regulation in piping systems. Its abrasion and corrosion resistance can ensure that the valve’s long-term stable operation, and can be in the high temperature and high pressure environment to maintain sealing performance.

Pump body and pump fittings: PEEK material for its excellent mechanical properties and corrosion resistance, often used in the petroleum industry for the manufacture of pump body and pump fittings. These components need to be able to withstand the impact of high pressure and corrosive media, and can maintain the stability and reliability of the process used in oil well injection, pumping and transmission.

Cable Sheathing and Splices: PEEK materials are also commonly used as cable sheathing and splices in the petroleum industry to protect the cable system from the external environment and to maintain stability and insulation under high temperatures and corrosive media.

6. Mechanical Equipment

Bearings and sliding parts: PEEK materials are often used as bearings and sliding parts in the manufacture of mechanical equipment due to their excellent wear resistance and self-lubricating properties. It reduces friction loss, extends the life of bearings and slides, and maintains stability at high temperatures and high speeds.

Gears and Transmissions: PEEK materials are also commonly used as gears and transmissions in the manufacture of machinery and equipment. Its high strength, rigidity and wear resistance can withstand high loads and high speeds of the working environment, and can maintain the stability and accuracy of the drive system for a variety of applications.

Seals and Gaskets: PEEK materials are often used to make seals and gaskets in machinery and equipment. These components need to be able to provide good sealing performance to prevent liquid or gas leakage, and can maintain stability and elasticity at high temperatures and high pressures.

Nozzles and Sprayers: PEEK is often used to make nozzles and sprayers for machinery and equipment due to its excellent abrasion and high temperature resistance. It is able to withstand high pressure and high temperature operating conditions and provides a stable spray effect for spraying, showering and cleaning applications.

Mechanical connectors: PEEK materials are also often used as connectors in the manufacture of machinery and equipment, such as bolts, nuts, washers and so on. Its high strength and rigidity can ensure the solidity and reliability of the connection, and can maintain stability and durability in a variety of working environments.

7. Electronic Industry

Connectors and sockets: PEEK materials are often used as connectors and sockets in the manufacture of electronic devices, such as PCB connectors and cable plugs. Their excellent insulating properties and high temperature resistance ensure the stability and safety of connectors, which are used for communication and power transmission between circuit boards and electronic components.

Insulators and isolators: PEEK materials are often used as insulators and isolators in the manufacture of electronic equipment, such as insulating gaskets and isolation boards, because of their good insulating properties. It can prevent current leakage and circuit interference to ensure the stable operation of electronic equipment.

Electrical contact parts: In the electronic field, PEEK material is also commonly used in the manufacture of electrical contact parts, such as sockets, terminals, etc.. Its good electrical conductivity and wear-resistant properties to ensure the stability and reliability of electrical contacts, used to connect electronic components and circuit boards between the conductive transmission.

Thermal management materials: PEEK materials are often used as thermal management materials in electronic devices, such as heat sinks, heat pipes, etc., because of their excellent high temperature resistance. It can effectively absorb and conduct the heat generated by the equipment, keep the temperature of the equipment stable, and can maintain stability in high temperature environment.

Cable Sheaths and Protectors: PEEK is also commonly used as cable sheaths and protectors in electronic equipment to protect cable systems from the external environment. Its abrasion and chemical resistance protects cable systems from mechanical damage and chemical corrosion, ensuring the stability and reliability of electronic equipment.

8. Deep Sea Exploration Industry

Sonar Array Components: PEEK materials are often used to manufacture array components in deep-sea sonar equipment, such as sonar sensor housings and support structures. Their corrosion resistance and mechanical strength protect sonar equipment from seawater erosion and high pressure environments.

Deep-sea connectors: In deep-sea exploration equipment, PEEK is also often used as a material for the manufacture of connectors, such as pipe joints, valves and pumps. Its corrosion resistance and high strength can ensure the stable operation of connectors in the deep sea environment.

Sensors and Detectors: PEEK is commonly used in the manufacture of sensors and detectors for deep sea exploration equipment, such as pressure sensors, temperature sensors and underwater camera housings. Its excellent mechanical properties and chemical inertness can protect the internal electronic components from seawater erosion and high pressure to ensure the stability and reliability of the equipment.

Shields and covers: PEEK materials are also often used as shields and covers in deep-sea exploration equipment to protect sensitive components from the external environment, such as protective covers for underwater cable connectors and covers for sonar sensors. Their corrosion and temperature resistance ensures long term stability in deep sea environments.

9. Medical industry

Orthopedic Implants: PEEK materials are often used in the manufacture of orthopedic implants such as bone plates, bone screws and interbody fusion devices. Their excellent biocompatibility, corrosion resistance, and mechanical properties make them ideal for orthopedic implants, and their modulus of elasticity is similar to that of human tissue, which helps to minimize patient discomfort and allows for long-term stability in the body.

Surgical Tools and Instruments: PEEK materials are also commonly used in the manufacture of a variety of surgical tools and instruments, such as surgical forceps, blades, and brackets. Its high temperature, corrosion and abrasion resistance ensures that surgical procedures are conducted safely and efficiently without adversely affecting the patient.

Medical Devices and Instruments: In the medical field, PEEK materials are also commonly used in the manufacture of a variety of medical devices and instruments, such as pacemakers, artificial heart valves, drug delivery devices and so on. Their excellent biocompatibility and chemical inertness make them compatible with human tissues and do not cause rejection or toxicity.

Dental materials: PEEK materials also have important applications in the dental field, often used as the manufacture of dental implants, alveolar external fixation devices, dental models. Their biocompatibility, strength and abrasion resistance make them ideal for dental materials that meet the needs of patients and provide long-lasting treatment results.

Imaging Devices: PEEK materials are also commonly used to manufacture components for medical imaging devices, such as MRI trays, CT fixtures, and more. Their low dielectric constant and low magnetization ensure the accuracy and reliability of imaging devices without interfering with image results.

Let's get your projects started, together!

Get custom parts machined in high quality, delivery on time.