- Capabilities

-

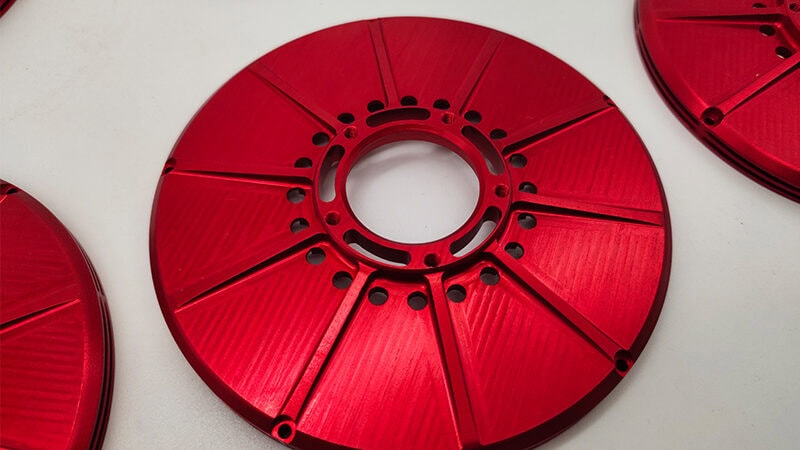

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

Home > Sheet Metal Fabrication Materials >Copper

Sheet Metal Fabrication Materials

Copper Sheet Metal Fabrication

Copper has excellent thermal and electric conductivity and is very formable, making it an exceptional material for sheet steel applications.

All uploads are secure and confidential

Copper Sheet Metal Fabrication

Industrial copper sheet steel has high purity scores and is generally supplied in two variations. Both of these variations include greater than 99% copper with the rest being contaminations like oxygen, lead, or silver. It is extremely flexible, making the use of copper for sheet steel applications simpler than various other much less ductile materials.

Copper has exceptional thermal and electric conductivity and is highly formable, making it an exceptional product for sheet steel applications. Due to these homes, markets such as aerospace, auto, and chemical processing on a regular basis make use of copper for sheet metal construction.

Copper 101, or oxygen-free copper is a highly pure type of metal (99.99% Cu). This high purity provides outstanding conductivity, so it is usually referred to as HC (high conductivity) copper. It is highly ductile and though it has a tendency to work harden, it does so at a sluggish rate. C101 can be hardened to make it less complicated to create. This high level of conductivity and ductility make it ideal for electrical sheet steel applications like basing strips, anodes, and breakers.

Coper 110, additionally known as T2, “C11000” or “Cu-ETP,” is a usual sort of copper alloy. It is a high-purity electrolytic copper alloy, usually including over 99.9% copper. T2 copper is renowned for its high electric and thermal conductivity, and it has widespread usage in electronic devices, electrical design, telecoms, and numerous other applications. It is frequently utilized in the manufacturing of electrical wires, cable televisions, published circuit boards, and electric components. T2 copper is an important design product, particularly in applications where excellent conductivity is called for.

Copper Sheet Metal Fabrication Surface Finishes

Copper Sheet Metal Fabrication Advantages & Disadvantages

Advantages

- Excellent Conductivity and Thermal Conductivity: Copper is renowned for its outstanding electrical conductivity, making it crucial in electrical and electronic applications such as wiring and circuitry.

- Malleability: Copper is highly malleable, which means it can be easily shaped and formed into intricate designs.

- Corrosion Resistance: Copper exhibits resistance to corrosion in many environments, making it suitable for plumbing and outdoor applications.

- Recyclability: Copper is a recyclable material, contributing to sustainability efforts by reducing resource waste.

Disadvantages

- Weight: Copper is relatively heavy compared to some other materials, which may be a consideration in certain applications.

- Cost: Copper's purity and performance can make it relatively expensive, potentially impacting its economic viability in some cases.

- Oxidation: Copper tends to oxidize gradually when exposed to oxygen and moisture, forming a surface patina, although this does not affect its core performance.

Copper Sheet Metal Fabrication Application

Electronics

Electrical and Electronics: Copper is widely used in electrical wiring, cables, circuit boards, and electrical connectors due to its excellent electrical conductivity.

Pipe

Pipes and Plumbing Systems: Copper pipes are utilized in water supply systems and plumbing due to their corrosion resistance and reliability.

Construction

Construction and Building: Copper can be used in architectural decoration, roofing materials, flashing, and drainage systems.

Artwork

Artwork and Sculpture: Because of its aesthetic qualities, copper is often used in sculptures, decorative artwork, and musical instruments.

Container

Food Contact Materials: Copper's corrosion resistance and non-reactive nature make it suitable for manufacturing food processing equipment and kitchen utensils.