- Capabilities

-

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

Surface Finishes

Heat Treatment Services

Heat treatments can be applied to many metal alloys to drastically improve key physical properties, including hardness, strength, and machinability.

All your designs are secure and confidential

Heat Treatment

Heat treatment is a controlled and systematic process employed to modify the physical and mechanical characteristics of materials, particularly metals and alloys. Through carefully calibrated heating and cooling cycles, this method aims to enhance specific properties such as hardness, toughness, and ductility. By subjecting materials to precise thermal conditions, heat treatment mitigates internal stresses, refines microstructures, and ultimately tailors the material’s performance to meet stringent engineering requirements. It is a vital manufacturing technique widely utilized across industries to optimize the strength, resilience, and overall quality of various components.

| Applicable Materials | Color Options |

| Steel | Black(Usually) |

Heat Treatment Parts

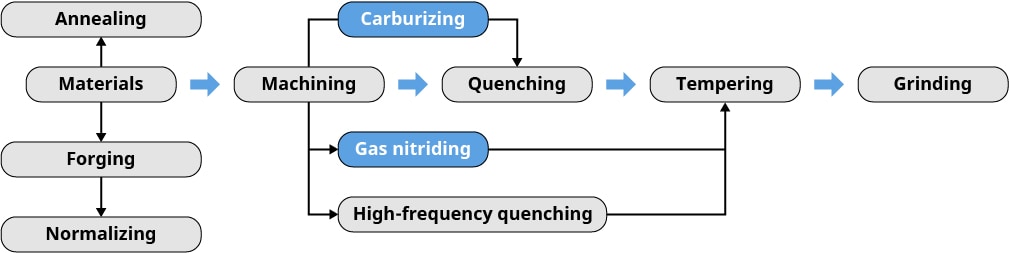

Heat Treatment Process

Heat treatment is the procedure of controlled heating & cooling of a material to preferred material or commercial properties. It alters four of the main product homes of metal parts, which are firmness, strength, toughness, and ductility.

- Heating: The material is heated to a specific temperature range, which varies depending on the desired outcome. This phase can include heating to austenitizing temperatures.

- Holding: The material is held at a certain temperature for some period, allowing for a uniform temperature distribution throughout the material's structure.

- Quenching: The material is rapidly cooled, or quenched, in such as oil, water, or air, to achieve the desired hardness or other mechanical properties.

- Tempering: In some cases, the material is then tempered by reheating it to a lower temperature. Tempering helps reduce brittleness and achieve the desired balance of hardness and toughness.

Heat Treatment Design Consideration

You can apply heat treatments to metal alloys at different phases of the CNC machining process, either before you begin machining your components or after.

Before CNC machining

When a standardized grade of a metal alloy is requested that is readily available, the CNC service provider will machine the parts directly from that stock material. This is often the best option for reducing lead times.

After CNC machining

Some heat treatments significantly increase the hardness of the material or are used as a finishing step after forming. In these cases, the heat treatment is applied after CNC machining, as high hardness reduces the machinability of a material. For example, this is standard practice when CNC machining tool steel parts. The parts after heat treatment need to be CNC machined again

FAQs

Heat treatment is a controlled process of heating and cooling materials to modify their mechanical properties in CNC machining.

Common materials for heat treatment include steel, aluminum, and various alloys used in CNC machining.

Common methods include annealing, tempering, quenching, and case hardening, each serving different purposes.

Heat treatment can cause slight dimensional changes in CNC-machined parts, which are considered during design.

Yes, heat treatment can be used for both ferrous (iron-based) and non-ferrous metals.

Heat treatment is generally considered environmentally friendly when proper processes and waste disposal methods are employed.

Sometimes, post-treatment machining is needed to achieve precise tolerances after heat treatment.

Yes, heat treatment is suitable for batch production, ensuring consistent material properties across multiple parts.

Quality checks include hardness testing, microstructure analysis, and dimensional inspections to verify material properties.