- Capabilities

-

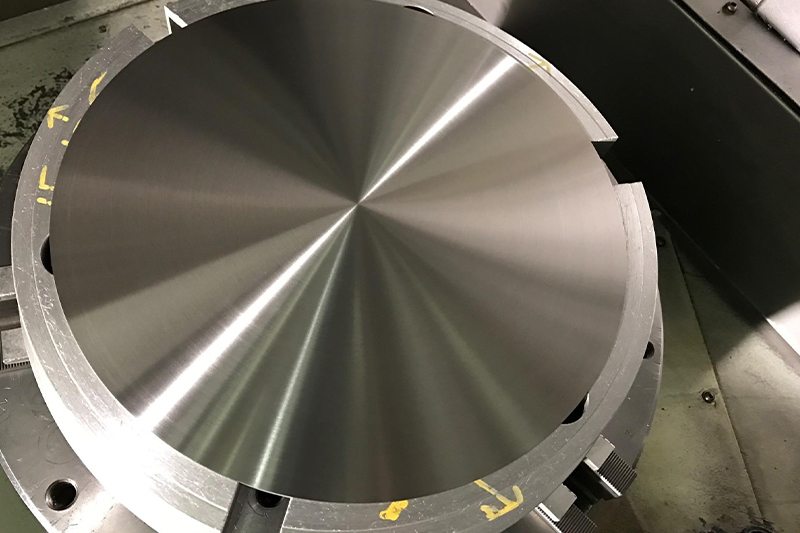

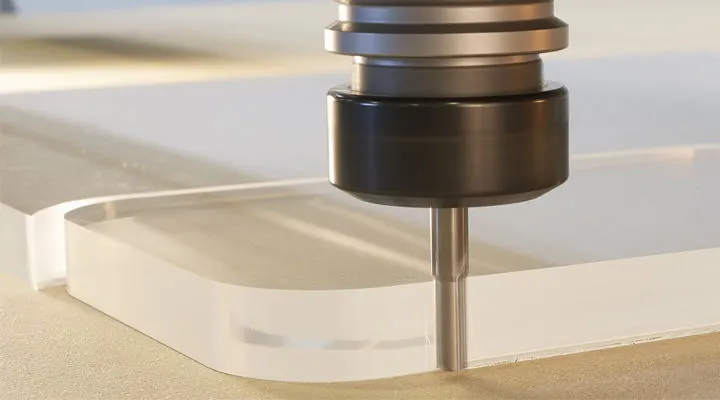

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

Home > CNC Machining Materials > Plastics > PC

CNC Machining Materials

Polycarbonate CNC Machining

Polycarbonate (PC) is a thermoplastic with high toughness, excellent impact stamina, and excellent machinability. Can be optically clear.

All uploads are secure and confidential

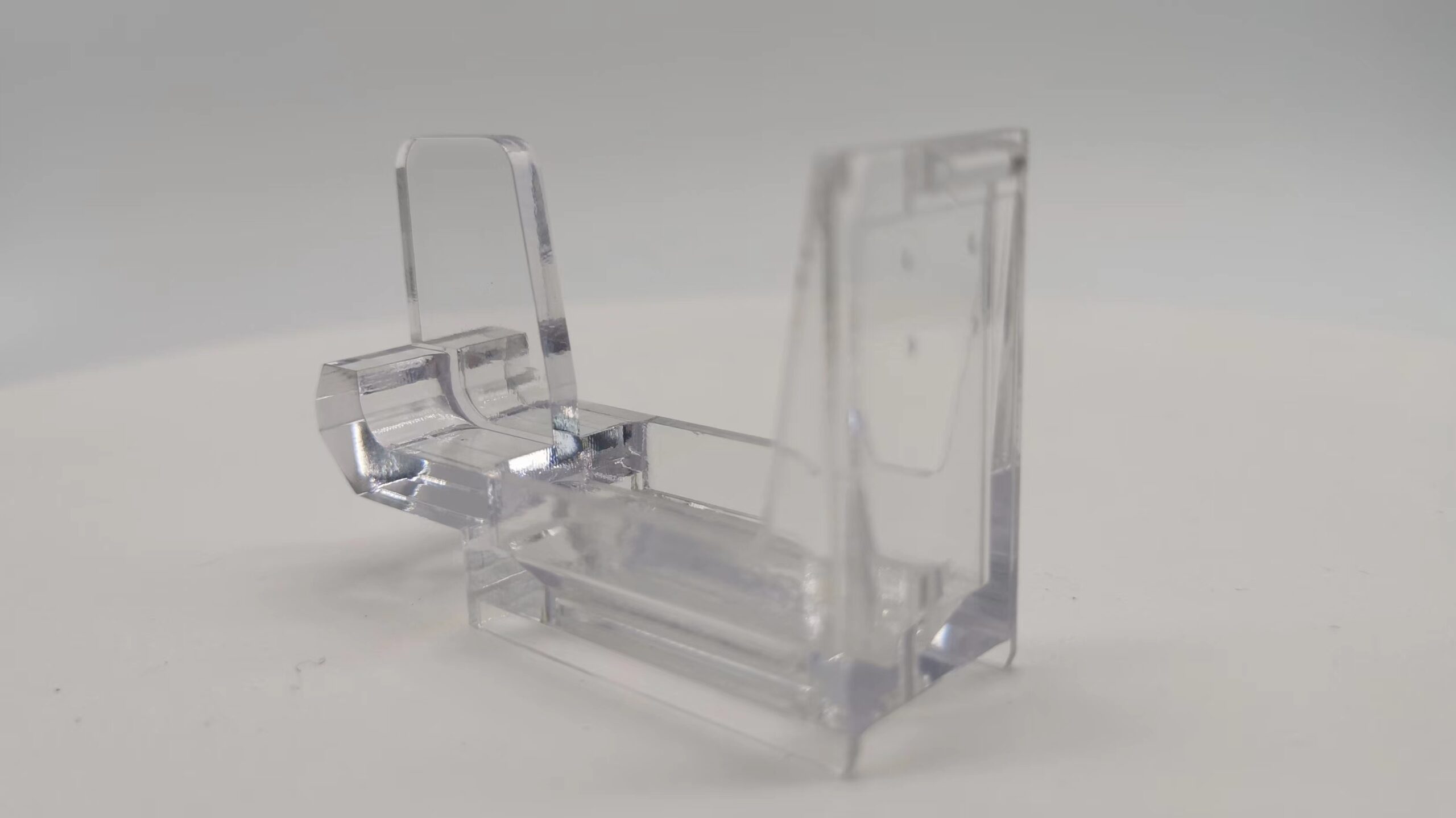

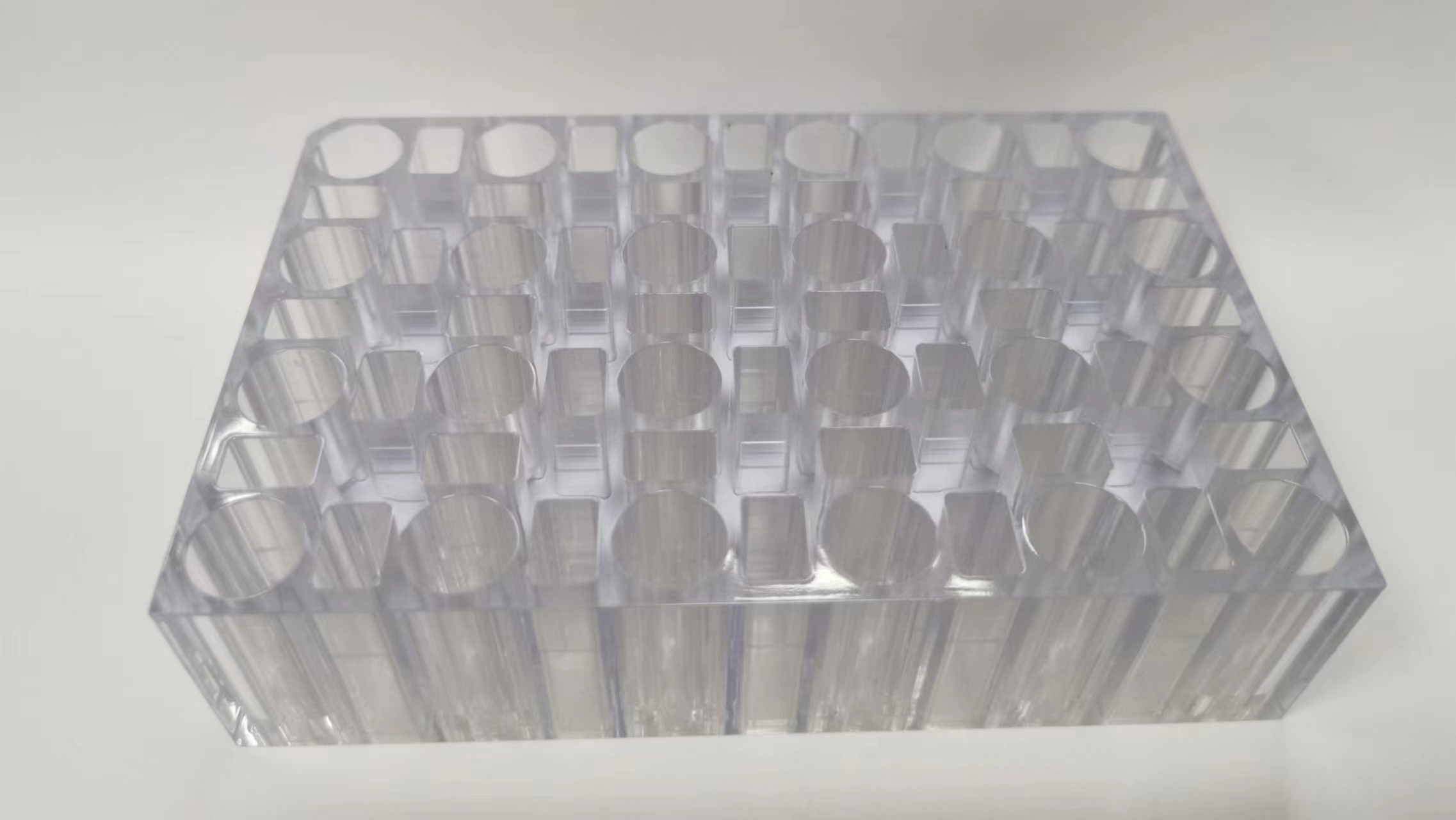

Polycarbonate CNC Machining

PC (polycarbonate) is an amorphous thermoplastic recognized for its high impact resistance and transparency. It likewise demonstrates great electrical insulation properties and modest chemical resistance.

Compared to various other engineering plastics, it is able to withstand effects while simultaneously supplying optical clarity, UV resistance, and higher-than-normal temperature resistance.

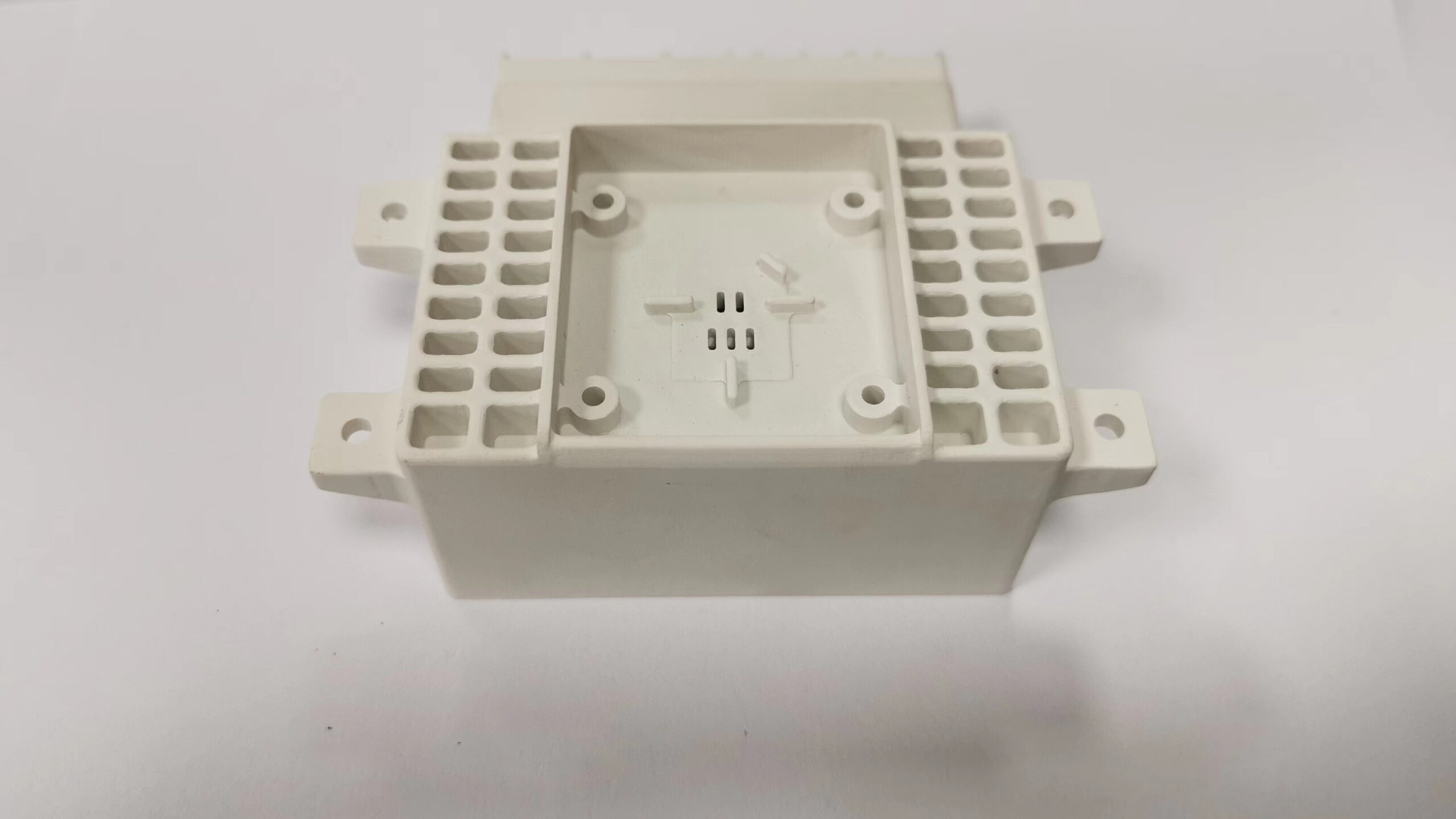

CNC machining in polycarbonate is reasonably prominent. The material’s remarkable effect resistance makes it excellent for architectural components. With the virtually dual impact strength of ABS, polycarbonate shows one of the highest impact strengths of all the usual engineering plastics. It is easily formed without cracking or damaging.

CNC machined polycarbonate is readily available in black or clear sheet and bar supply. Its clearness, shatter resistance, and lighter weight make it a superb replacement for glass. It also takes care of heat much better than acrylic.

CNC machining in polycarbonate does not naturally yield optically clear components, so some more ending up is required.

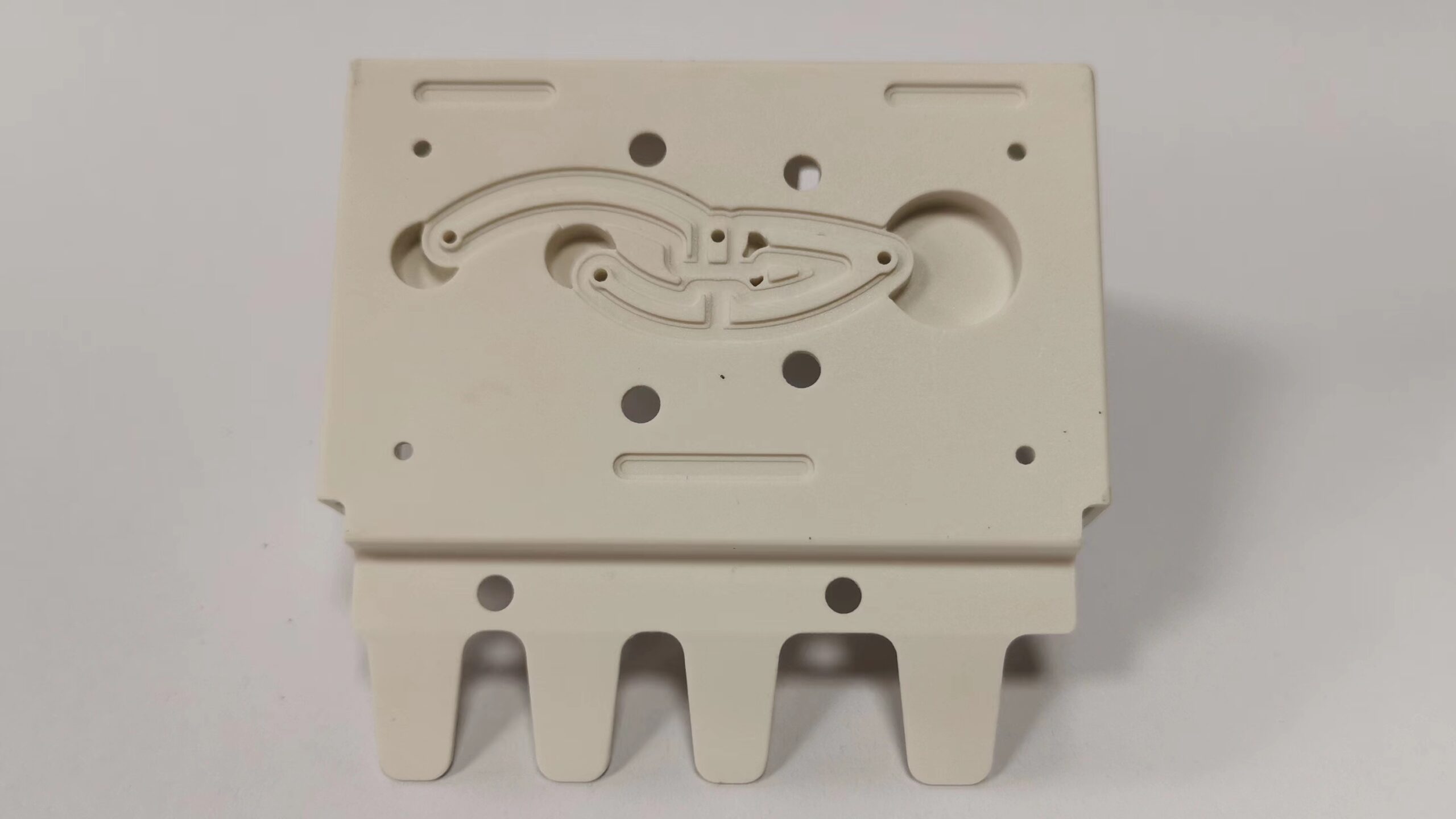

PC is typically used in the automobile sector for the manufacturing of cockpit consoles, pumps, shutoffs, and more. It is also utilized in other markets for the manufacturing of safety gear, clinical gadgets, internal mechanical components, and more.

Check our blog on CNC machining polycarbonate guides.

Polycarbonate Properties

| Ultimate tensile strength | Yield strength | Young’s modulus (modulus of elasticity) | Elongation at break | Hardness | UV resistance | Application | |

| 60 – 72.4 MPa | 59- 70 MPa | 2 – 2.44 GPa | 50 – 120 % | 17.7 – 21.7 HV | Fair | Power distribution (covers and housings) Connectors Battery boxes | Learn More |

Polycarbonate CNC Machining Surface Finishes

Cost-saving Design Tips

Polycarbonate is a fairly expensive plastic. Listed below are some cost-saving design tips.

Sub-assemblies

PC for machining is provided in either sheet or bar supply. As such when CNC machining in polycarbonate it is essential to make parts with standard dimensions in mind. Huge components machined from a single block of polycarbonate can become excessively expensive. Instead, take into consideration creating different sub-assemblies that will certainly later on screw with each other or get merged via plastic welding.

Consistent features

Design with consistent functions in mind to decrease specialized tooling or device changing.

FAQs

Machine-Grade Polycarbonate is an amorphous thermoplastic, transparent and possessing high impact strength and exceptional dimensional stability. It is often used for structural applications where transparency and superior impact strength and rigidity are essential. Machine grade polycarbonate is stress relieved, making it ideal for close tolerance machined parts. Its low moisture absorption rate and its chemical resistance makes machine-grade PC extremely versatile as an engineering material and allows for its use in an abundance of industrial applications.

Polycarbonate is stronger than acrylic and has 250X the impact resistance of standard glass. Polycarbonate is ideal for highly demanding applications due to it’s higher resilience, as compared to acrylic. Acrylic is also easier to crack, while polycarbonate is easier to scratch.

Polycarbonate is one of the most common plastics used in manufacturing. Its high strength and light weight are valued for making shatterproof windows, eyeglass lenses, CDs, DVDs, mobile phones, and more. It’s most famous examples of uses for the material are first-generation MacBook laptops, safety goggles, and optical disks.