- Capabilities

-

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

Home > CNC Machining Materials > Plastics > FR4

CNC Machining Materials

FR4 CNC Machining

FR4 is an electrical-grade, dielectric fiberglass laminate epoxy resin system incorporated with a glass substrate.

All uploads are secure and confidential

FR4 CNC Machining

Constructed of an epoxy material with fiberglass textile support, also called epoxy-grade industrial laminate and phenolic, this product supplies high strength and reduced wetness absorption.

FR4 and G10 are glass fiber-reinforced epoxy resin materials.

FR4 is an electrical-grade, dielectric fiberglass laminate epoxy resin system incorporated with a glass material substratum.

The difference between G10 and FR4 is that FR4 is a fire-retardant quality of G10 and can be safely replaced when G10 is called out.

FR4 CNC machined parts has exceptionally high mechanical strength, excellent dielectric loss buildings, and outstanding electrical toughness residential properties, both damp and completely dry.

FR4 CNC machining service is widely used in producing PCBs for devices such as computers, mobile phones, automotive electronics, and many other electronic systems. A reliable and durable substrate is essential for the electronic circuitry to function adequately.

FR4 Properties

| Ultimate tensile strength | Yield strength | Young’s modulus (modulus of elasticity) | Elongation at break | Hardness | UV resistance | Application | ||

| FR4 | 240 – 310 MPa | 12 – 27 GPa | 0.008 – 0.01 % | 100 – 110 HRM | Good | Structuralapplications Electrical applications PC boards | Learn More |

FR4 CNC Machining Surface Finishes

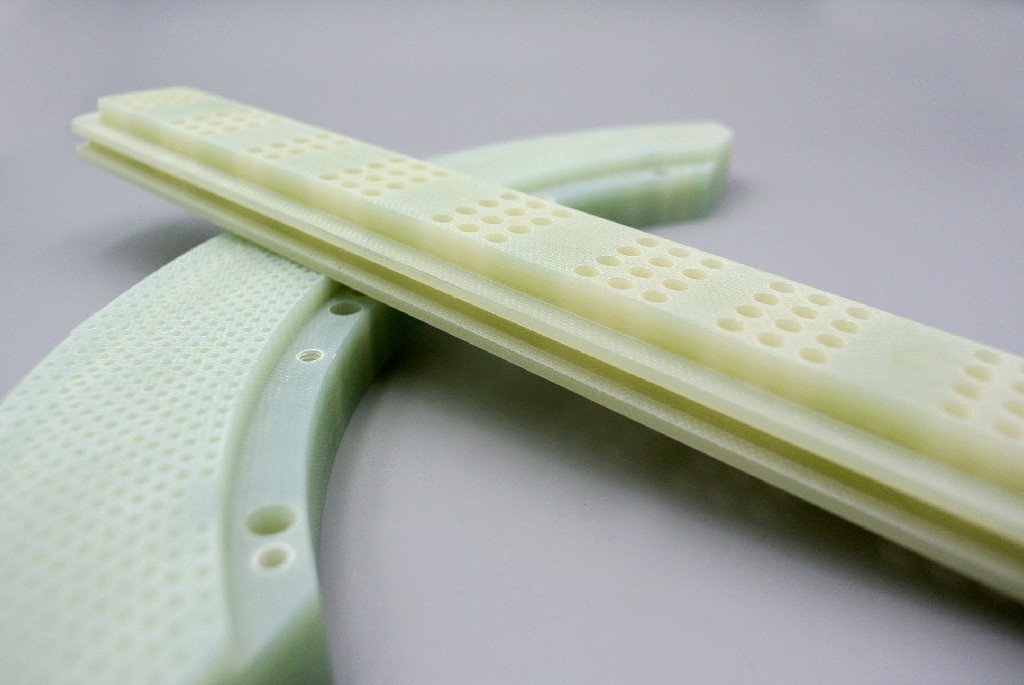

FR4 CNC Machining Gallery

Cost-saving Design Tips

To reduce costs, limit part setups numbers, inspection dimensions or tight tolerances numbers, and deep pockets with small radii.

FR4 CNC Machining FAQs

The difference between G10 and FR4 is that FR4 is a fire-retardant grade of G10 and it can be safely substituted when G10 is called out.