- Capabilities

-

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

Surface Finishes

Painting Spray Services

Provides a continuous, protective shade surface which is applied by splashing or manually making use of water or solvent-based paints.

All your designs are secure and confidential

Painting Spray

Painting spray offers a constant, protective shade coating which is applied by splashing or manually making use of water or solvent-based paints. Colors can be matched to a Pantone shade number of the consumer’s picking, while coatings range from matte to gloss to metal.

Painting spray is also well-known as spray painting, wet painting, and liquid painting.

Painting the surface area of a component improves its aesthetic appearance and can give brand acknowledgment to customers. Furthermore, paint can have a protective result on parts. For example, surface paint is a reliable approach to secure steel from oxidation and corrosion.

| Applicable Materials | Surface Preparation | Colors | Glossiness | Surface Texture | Cosmetic Availability | Visual Appearance |

| Metals,Plastics | As machined (Ra 1.6μm) | White, Black, and Pantone | Glossy/Matte | Flat/Texture | On request | Parts are painting sprayed directly after machining. |

Painting Spray Parts

SLA Parts Painting Spray

SLA Parts Painting Spray Detail

Painting Spray Process

- Surface Preparation: Clean and prepare the part’s surface by removing contaminants and imperfections.

- Primer Application: Apply a primer coat to enhance adhesion and corrosion resistance.

- Paint Mixing: Prepare the paint with the right color and type, adjusting viscosity if needed.

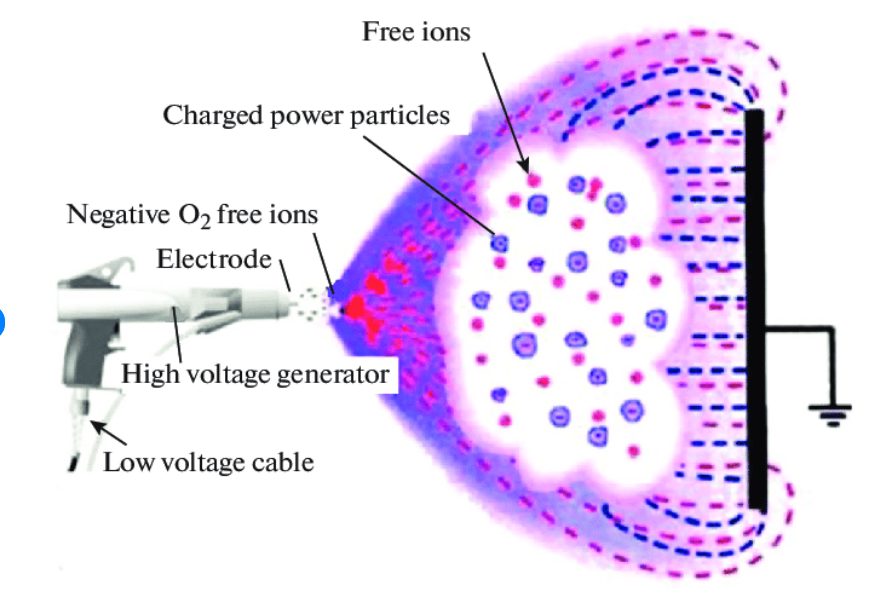

- Paint Application: Use a spray gun to evenly apply the paint to the part’s surface.

- Curing/Drying: Allow the paint to dry or cure, ensuring proper adhesion and hardening.

- Quality Inspection: Inspect for imperfections and correct any defects.

- Finishing (Optional): Apply additional coatings or textures as required.

- Final Drying and Curing: Thoroughly dry and cure the part for the desired appearance and properties.

Painting Spray Design Consideration

- A well-prepared surface ensures better paint adhesion and a smoother finish.

- Mask off areas that should not be painted using painter's tape and protective coverings.

- Conduct a test spray on a small, inconspicuous area to ensure compatibility between the paint and the surface.

FAQs

Painting spray is the process of applying liquid paint or coating to CNC-machined parts to enhance their appearance and provide protection.

Painting spray offers a wide range of color options, corrosion resistance, and the ability to achieve specific aesthetic requirements.

Various metals, plastics, and other materials can be painted, depending on the paint type and application method.

Yes, paint colors can be customized to match specific color codes or preferences.

Painting spray finishes and textures can vary to meet specific aesthetic and functional requirements. Some common painting spray finishes and textures include:

Smooth Finish: This finish is smooth, even, and provides a glossy appearance.

Matte Finish: Matte finishes offer a non-reflective, flat appearance, free of gloss.

Satin Finish: Satin coatings provide a soft, semi-gloss finish with some level of reflection.

High-Gloss Finish: High-gloss coatings create a highly reflective, shiny surface.

Textured Finish: Textured coatings add tactile elements with fine or coarse textures.

Metallic Finish: Metallic coatings mimic the appearance of various metals, including gold, silver, and bronze.

Hammered Finish: Hammered coatings produce a textured surface, often with a rugged or hammered appearance.

Vein Finish: Vein coatings replicate the look of natural stone patterns, creating a luxurious aesthetic.

Antique Finish: Antique coatings create an aged, weathered, or vintage appearance.

Clear Coating: Clear coatings protect the underlying material while maintaining its natural appearance.

Painting spray does not provide electrical insulation; it primarily enhances appearance and protection.

Spray conductive paint, also known as conductive coating or conductive spray, is a type of paint formulated with conductive materials such as metal particles, carbon, or graphene. It is designed to create a conductive surface when applied to non-conductive materials, such as plastics, ceramics, or non-metallic substrates.

Spray conductive paint is commonly used in various applications, including electronics, where it can provide electromagnetic shielding, create electrical connections, or dissipate static electricity. It allows non-metallic components to become electrically conductive, making it useful for a wide range of industries and products, from printed circuit boards to anti-static coatings on equipment.

In most cases, post-painting treatments are not required, as painting spray provides a complete finish.

Paint is evenly applied using a spray gun or other application methods, ensuring a uniform coating.