3D Printing Services for Custom Parts

What is 3d printing?

3D printing or additive manufacturing (AM) technologies create three-dimensional parts from computer-aided design (CAD) models by successively adding material layer by layer until physical part is created. As additive manufacturing processes build objects by adding material layer by layer, 3d printing offers a unique set of advantages over traditional subtractive and formative manufacturing processes, including faster speed, lower cost, customization, design freedom, and reduced risk.

3D printing is commonly used for rapid prototyping and low volume production parts.

3D Printing Capabilities

Stereolithography (SLA)

- Dimensional accuracy of ±0.2% with a lower limit of ±0.127mm

- Lead times from 2 businessdays

Selective Laser Sintering (SLS)

- Dimensional accuracy of ±0.3% with a lower limit of : ±0.3mm

- Lead times from 3 businessdays

Multi Jet Fusion (MJF)

- Dimensional accuracy of ±0.5% with a lower limit of ± 0.5mm

- Lead times from 3 businessdays

Fused Deposition Modeling (FDM)

- Dimensional accuracy of ±0.05% with a lower limit: ±0.05 mm

- Lead times from 1 business day

Selective Laser Melting (SLM)

- Dimensional accuracy of ±0.2% with a lower limit of ±0.1mm

- Lead times from 3 businessdays

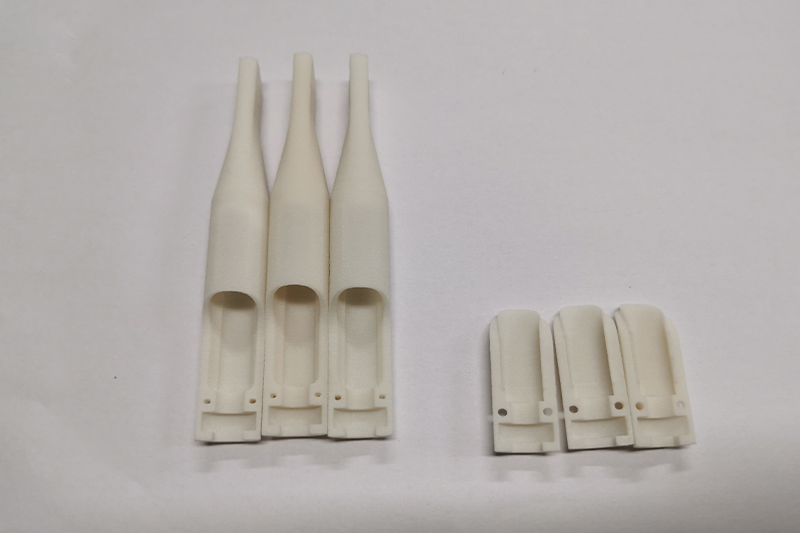

3D Printing Parts Gallery

3D Printing Materials

SLA

- Standard resin

- Transparent resin

- Translucent resin

SLS

- PA12

- PA12 glass filled

MJF

- HP PA 12

- Glass filled HP PA 12

- HP PA 11

FDM

- PLA

- PETG

SLM

- AL AlSi10Mg

- SS 316L

- Titanium TC4

- Die Steel MS1

- Copper

3D Printing Post-processing

SLA Parts

- Hand polish

- Vapor Polishing

- Painting spray

SLS Parts

- Hand polish

- Color dyed

- Painting spray

MJF Parts

- Hand polish

- Color dyed

- Painting spray

FDM Parts

- Hand polish

SLM Parts

- Hand polish

- Sandblasting

- CNC machining

Why ECOREPRAP 3D Printing

Consistent Quality Every Time

For 3D-printed products, we go the extra mile by removing any residues and manually polishing them after printing.

Photos and videos will be sent to customers for confirmation for assembly components of 3d printing parts.

Strong Manufacturing Capacity

We boast a robust and extensive array of 3D printing services technologies, including SLA, SLS, MJF, FDM, and SLM.

From plastics to metals, we offer a comprehensive suite of 3D printing processes to cater to your prototyping and production needs.

Professional Engineering Support

Work with our engineering experts that offer technical design guidance and inform you on manufacturability and cost-saving solutions.

Free and accurate quotation with DFM review in 12 hours and lead time as fast as 1 day.

Worldwide Shipping Solution

Through international express DHL/FEDEX, you will receive qualified partswithin 3 to 7 days.

For bulk orders, seaor rail transportation services are pro-vided to reduce the shipping cost.

Other Machining Services

Precision CNC Machining Services

Get your parts CNC machined in 50+ metals and plastics. From one-off prototyping and on demand production, all your needs can be met here.

Sheet Metal Fabrication Services

Get your sheet metal fabrication parts in 20+ metals. From one-off prototyping and on demand production, all your needs can be met here.

Vacuum Casting Services

Vacuum casting is a custom manufacturing method used for the production of small series of functional plastic parts, materials including ABS-Like,PMMA-Like,PC-Like,PP-Like,Rubber-Like, Silicone.