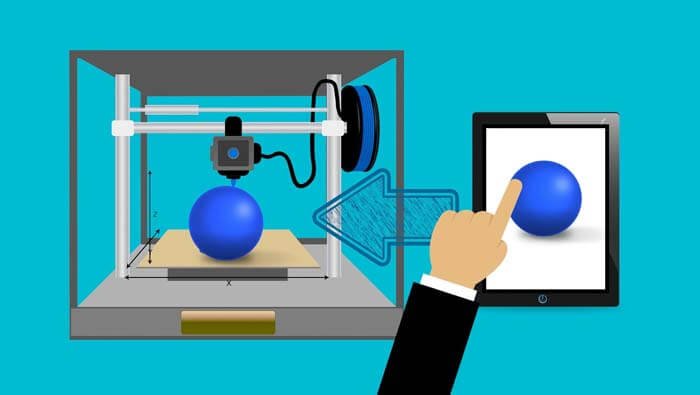

3D printing is a process where you can make three-dimensional models from a digital file. The printing process makes layers one on top of the next to create these models, and there are many materials, also called filaments, that are used. You can make many items, such as prototypes, surgical tools, movie props, and more.

How Does 3D Printing Work

The first step is making the digital version of the model you want to print. You can use a 3D scanner, an app, code, or 3D modeling software. There are many software programs, and many are available for free. Once you choose the right model software, you can design your model. Meanwhile, You also could download the files from 3d model marketplaces. There are so many models resource on other sites, free and paid.

After confirming the model need to print, the next step is converting STL files to g code format, 3d printer only supports this type of date. The last step is setting with printers, such as nozzle and heated bed temp, speed, and infill.

Who Uses 3D Printing?

3D printing is widely used in many fields. There are plenty of materials that can be used to print 3D objects that it has become more and more widespread. One major use of 3D printing is in making prototypes and models. The process reduces the time and cost of building an expensive model, and the project can be ready in just a few days.

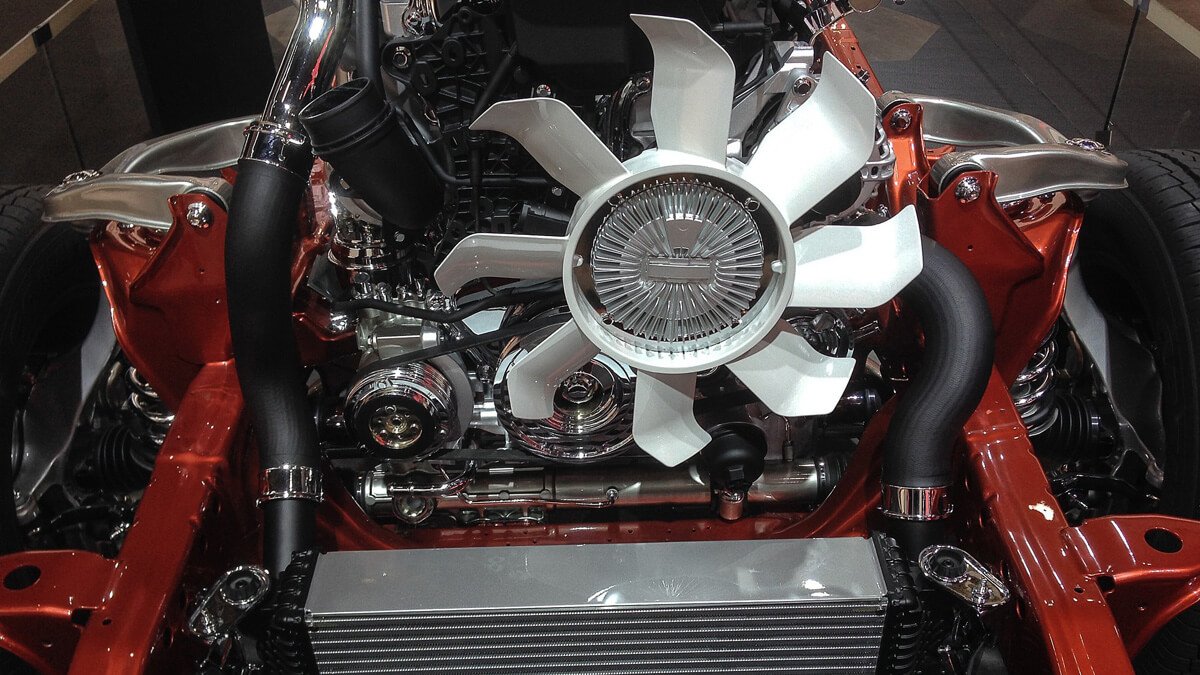

1. Automotive and Aviation

One common use for 3D printing is in the automotive industry. They print spare parts for cars and tools, and they can use 3D printing to help restore old car models. The Aviation industry also uses 3D printing for parts and it has made engine making and other aspects of aviation much simpler than before.

2. Construction and Architecture

In the construction industry, 3D models are very useful to show a project in the form of a model before the project is undertaken. In addition, they are now actually building doors, floors, and other parts of a structure.

3. Consumer Goods

3D printing is used for many consumer products. The soles of shoes, eyeglasses, jewelry, and more are all using 3D printing to make consumer products.

4. Healthcare

3D printing is used for the creation of prosthetics, surgical tools, and replicas or models of bones, organs, and blood vessels. In the dental industry, it can be used to make teeth.

The list is vast, as 3D printing can benefit so many industries. The materials that are used as 3D filaments are extensive, as well.

What Materials Are Used to Print 3D

The materials used to print in 3D are called filaments. They are fed into a 3D printer, where they are heated to the melting point. Then, the material is extruded through a nozzle and prints layers on the printing bed. The melting point varies from material to material, and different types of filament are better suited for different projects. The applications for each filament are largely dependent on its strength and melting point.

Advantages of 3D Printing

1. Rapid Prototyping

Three-dimensional printing speeds up the process of creating prototypes significantly. It is a quick, cost-effective, and simple way to develop a prototype in a matter of hours. Prototyping is used frequently to test designs because it is accurate and fast. This is beneficial to the manufacturing process because companies can make the design happen much more quickly, sometimes even the next day.

In addition, there is less waste when 3D printing is used because it only prints the model. In the past, molds had to be made which led to greater waste. In addition, the cost of the prototype is reduced because it can be made quickly and it has less wasted material.

Companies can test their designs much more quickly and make changes before they go into mass production. Once a rapid prototype is successful, the company can go to production with a reliable design. Prototypes are fully functional models, so they can be tested and modified when they are made

2. Demand Printing

Another huge benefit is that companies can print their models on demand. They do not need to store a lot of excess inventory because items can be printed as they are needed. The models are stored as digital files, and when a model is needed, it can be printed for the order. Businesses do not need to overstock as they can print exactly what they need when they need it.

This is beneficial on many levels. Companies will not need to put money out to make parts or products that sit on the shelves until a sale. Because items can be printed on demand, the customer will order the part, and it can be printed within a few days and shipped out.

3. Design Flexibility

Three-dimensional printing has incredible design flexibility because it can produce complex items that former processes may not have been able to make. There are no molds in 3D printing, and the mold used to cause limitations on the shapes of certain parts. With 3D printing, the entire process is simplified and the result is the ability to easily create more complex items.

The 3D printing process can maintain the strength of items by providing support only where it is needed. This in turn allows for intricate designs without excess materials, and the resulting product is efficiently produced.

4. Reduction of Waste

Three-dimensional printing is an additive manufacturing process, meaning that the only material that is used is what is needed to produce the part being made. This is vastly different from processes that cut models out of non-recyclable materials with a tremendous amount of waste. Not only is 3D printing more efficient, but it significantly reduces waste, which reduces the cost because companies are only using the material they need. This translates into better pricing for the consumer as well.

5. Environmentally Friendly

Three-dimensional printing is a newer technology, so there haven’t been any significant studies done on the long-term impact on the environment. However, the efficiency and the fact that it eliminates significant waste is definitely environmentally friendly. In addition, it only uses energy during the printing process, which is beneficial.

Some 3D printing products are biodegradable, and they are also environmentally friendly. The fact that printing can be done in such a way that manufacturers can produce products on demand also leads to a reduction in waste. This reduces the impact of making and transporting products that may never be used. Fewer outdated parts will end up in landfills as well.

Studies are being done by institutions such as Yale University, and one thing is agreed upon, which is that the reduced waste is beneficial to the environment. Three-dimensional printing seems to be a sustainable manufacturing process.

6. Custom Designs

Three-dimensional printing is designed with software most of the time, and the ability to create complex geometrical shapes leads to an ability to customize designs to create unique products. It is easy to take a prototype and make changes to customize each one for individual customers. This opens the door to much greater opportunities, especially in the dental and medical fields.

In the Healthcare Industry, 3D printing is used to create custom prosthetics, dental implants, and other dental aids. They also make many surgical tools with 3D printing. Three-dimensional printing is revolutionizing the healthcare industry.

Consumer goods also benefit from 3D printing. Companies make customized products including high-quality shorts wear to fashion accessories. Using the additive manufacturing process of 3D printing, companies can make one-time customized items for specialized athletes or accessories for movie sets.

7. Easy Access

Although additive manufacturing has been practiced for over 30 years, it has experienced extraordinary growth since 2010. As more materials are developed for the 3D printing process, 3D printing is set to explode even further, and it is readily available and competitive in pricing. It is used across a broad range of industries, and the number of companies offering 3D printing services is growing as well.

Three-dimensional printing is accessible to just about anyone who wants it today. As it becomes a mainstream staple for manufacturing, this will only continue to grow.

8. Risk Management

Three-dimensional printing allows companies to more effectively mitigate risk because they can create a rapid prototype and test the design. If there are any flaws or faults, or even if the customer wants to change it, it can be done effortlessly.

In the past, companies needed to create a mold before they could even begin to make a prototype. This step is eliminated, and the design goes right from a digital file to printing, and it can be changed and edited as necessary. This greatly reduces the risk to a company in trying out innovative new designs and products.

9. Lower Cost

Manufacturing cost is made up of three different categories, including material cost, labor cost, and machine operation costs. Three-dimensional printing reduces the costs in all three categories. The material cost is lower because additive printing has no waste. There is no excess material that needs to be cut out. The material that is used is only there to produce the model.

In addition, the labor is reduced because companies only need one person to operate the 3D printing machine. This is especially true when companies order a prototype to test. If multiple models are needed, there could be more labor involved, but never as much as older manufacturing techniques.

Finally, the cost of machine operation is lower. The largest expense is the filament, which is the material used. Different filaments will cost different amounts of money, but there is no waste, so every part of what you buy is used. Three-dimensional printing does use higher energy when it is in use, but even so, the overall cost is lower.

10. Manufacture on One Step

Often manufacturing is a multistep process, and 3D printing changes that. In the past, it was necessary to make molds, and then create products and remove them from the mold before moving on to the next part of the process.

With 3D printing, the design goes from the computer file to printing with no steps in between. The item is printed, and then it is ready to be sanded and painted, if necessary. It is a much faster process with only one step, which is beneficial all around.

11. Faster Production

A huge advantage is that items can be produced very quickly with 3D printing. Companies can create complex designs on a computer and upload them. These designs can be printed in a few hours.

In the past this process could take a significant amount of time, and the project was in a holding pattern until the product was available for inspection. In addition, when companies have an order, they can have it fulfilled much more quickly than in the past.

12. Better Quality Items

The way 3D printing works is to extrude the material through a nozzle once it is heated to its melting point. The 3D printing builds the model in a process of layering. This allows for step-by-step assembly of the item, so it is much easier to know when something needs to be changed or fixed.

Old processes would make products, but there was no way to know if there were air bubbles inside until a later time when the device failed. Now the entire process can be controlled from start to finish with the method of building products in layers.

13. Blended Raw Materials

Most manufacturing is unable to support the blending of materials, and even when they can, it can be very expensive. Three-dimensional printing can not only blend different raw materials, but it uses an incredibly diverse range of raw materials, including the following:

- Glass

- Metal

- Paper

- Wood

- Bamboo

- Ceramics

- Biomaterial

- Silver

- Precious metals

- Thermoplastics

The process is simplified in 3D printing, so it is possible to use the exact material that is best for each project, and it doesn’t slow the process down at all.

14. No Tools Needed

Manufacturing processes often require many expensive and specialized tools to produce the products. With 3D printing, this becomes unnecessary. The entire model is produced by the 3D printer without any other tools. You may need to sand or paint the product after production, but it will be built without any extra tools. This saves the manufacturer a lot of money.

15. Allows for Easy Proof of Concept

Proof of concept is evidence of an idea. It shows a model, and it differs from rapid prototyping because the model is not tested. This is very useful when a company needs proof of concept to patent the idea or generate support before it goes further into the design and production process.

Is 3D Printing the Wave of the Future

By all indications, 3D printing is growing rapidly and will be around for a long time. The speed of producing a prototype or proof of concept is the most widespread use today, but more and more industries are making use of this technology to create better designs and customizable products.

Studies are being done to determine the long-term impact on the environment, but there are some benefits, including reduced waste, that are beneficial. In the past, companies might order products that sat on the stockroom shelves for years before finally being left in a dump, and 3D printing changes that because orders can be printed on demand. The process is quick and efficient, so it isn’t necessary to order months ahead.

Conclusion

The rise in 3D printing along with its improved efficiency and diverse materials is changing the way manufacturers produce their items. Companies are using 3D printing to make parts for automobiles and jets, space shuttle parts, and more. Consumer goods manufacturers are making highly specialized fashion wear and athletic equipment, and other companies make packaging for food and other items.

Finally, the healthcare industry is making great use of this technology, as it allows the manufacture of customized prosthetics. Metal plates and screws used in surgery can also be made with materials that will degrade within six months, and there are many tools and devices made as well.

Many companies benefit from 3D printing because it is so much more efficient. It saves time, as shipping out designs is as simple as sending a digital file, and products are printed from this digital data. Items are printed in layers, which allows for close monitoring of the product for any flaws or revisions that might need to be made.

Three-dimensional printing is more popular all the time, and it is much more accessible than it was in the past. The growth of this industry has led to more creations, and it is easy to try out ideas at a fraction of the cost and time. There is no doubt that 3D printing is here to stay, and the process is continually being improved. It is beneficial across all industries, and the potential is significant.