- Capabilities

-

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

Hey, this is Lucas!

I want to help you understand the CNC industry more deeply and easily.

As a technical writer with relevant experience in the CNC industry, including operating, programming, quoting, and project management. Because of my experience in the industry, I can explain the related topics more deeply and try to present them in easy-to-understand language combined with pictures and videos.

“What is your story? How did you get started?”

CNC Machine Operator

Although I studied mold design and manufacturing in my junior college, my first job was a CNC operator, which is an interesting thing, isn’t it? Because I didn’t graduate in CNC, I only pressed START and PAUSE button in the beginning. After three years, I learned to set up and debug CNC machines, make program edits and adjustments, and check part quality and accuracy in production.

3 Axis CNC Programmer

One of the not-so-good things about being a CNC operator is that you have to work the night shift. I hate night shifts. So I started to learn CNC programming on the Internet. Two years later, I producedCNC machined parts with my programm as an machine operator. During this period, I mainly mainly UG and Master CAM etc. by 3-axis machine operation. Of course, with the improvement of programming level, I ended night shift work.

5 Axis CNC Programmer

While 3-axis technology can machine complex parts, the 5-axis machining is quietly emerging. I learned 5-axis programming again online. Because, 5-axis programmers are paid more and, of course, are more challenging. These 3 years were a perid of improvement in my 5-axis programming skills, although I occasionally handle 3-axis programming.

CNC Quotation Engineer

Well, I admit that I’ve never been the type to stay in one place for too long, always looking for new opportunities and trying out new positions. Whether it was as a machine operator or a programmer, I was always in the factory. The constant buzzing noise of the factory was ever-present, and I started wanting a quieter work environment, like an office. Becoming a quotation engineer seems a good choice.

At first, I only quoted parts based on the quantity and material list provided by sales, and did not provide any other support. Over time, I started to provide DFM suggestions and and I also started advising suppliers on potential machining difficulties. This job is very interesting to me, and my role as a bridge between customers and suppliers is very important.

CNC Technical Writer

CNC Technical writing is a new and interesting field for me. Because I can share what I know with more people. At the same time, I may need to do more research myself for a topic. I enjoy my current job.

More

During the COVID-19 pandemic in 2020-2021, I worked from home and had plenty of time. I took online courses in IT programming, learning HTML, CSS, JS, and more. This period of self-study unexpectedly helped me in my role as a CNC Technical Writer. Pretty cool, huh?

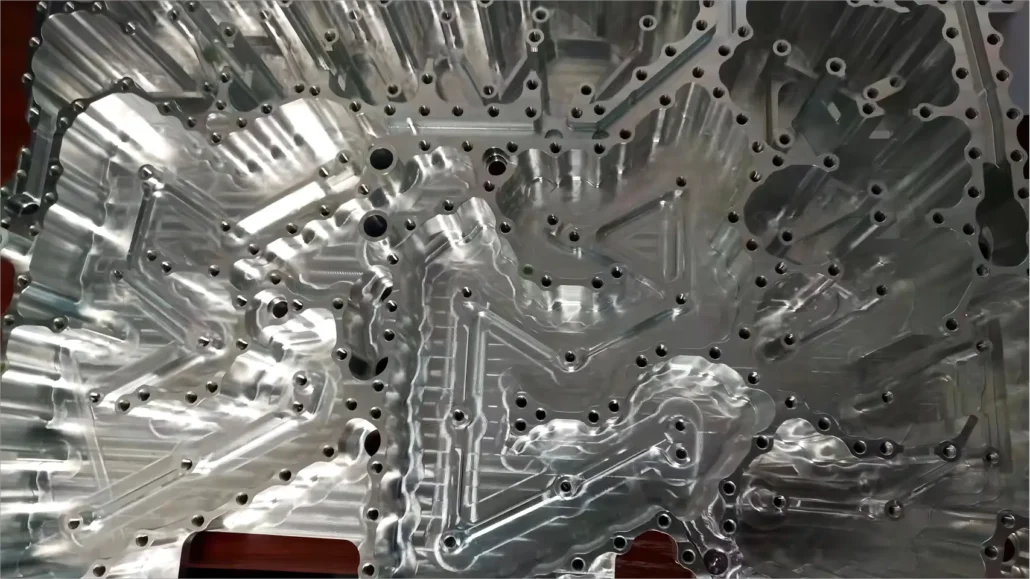

Two Impressive Projects

This is probably the most complex 3-axis programming I’ve ever experienced, and the most impressive project. The part size is about 400*500*400mm and is used in communication equipment.

It has a lot of steps and threads, a depth of about 40mm (go/no-go gauge check), and the sidewalls are all tapered. Taper knife we ordered four kinds of 60 pieces, inside and outside the wall does not allow vibration knife and scratches, the back of the tooling direction to be consistent.

Behind closed doors by ourselves, it took four days to complete the programming, and the first sample took a full 24 hours. Later on, it was optimized in mass production, which took 18 hours each. The finished product is splendid, and I have saved a small video of the first sample.

This was a multi-million sales project involving CNC machining, sheet metal fabrication, assembly, etc. The materials used were aluminum AL 6061T6, mild steel Q235, and plastics PC and Others.

Different surface treatments are applied, aluminum black Type II and Type II anodizing, Q235 textured black powder coated, Polycarbonate vapor polishing, and laser engraved serial numbers.

The challenge of the project was the color consistency and assembly requirements before shipment.

From quotation to delivery, the history of 2 months, more than 300 parts, the U.S. customer received, very satisfied.

Follow Me on Social Media

Join People Interested in CNC Worldwide.

Ring the bell on YouTube

Where I share you the best CNC machining knowledges.

Follow me at LinkedIn

My thoughts on CNC machining industries.