What Is Bead Blasting? Process, Media Types & Benefits Explained

Updated: Dec. 12, 2025

Table of Contents

Bead blasting is one of the most widely used surface-finishing processes in CNC machining, product manufacturing, and industrial design.

Whether you’re creating precision aerospace components, refining medical device housings, or improving the appearance of consumer electronics, bead blasting delivers a clean, uniform, and visually premium finish that other methods simply can’t match.

In this guide, we break down everything you need to know about bead blasting: how it works, the different types of blasting media, ideal applications, finish results, and the best practices professionals use to achieve consistent, high-quality outcomes.

Whether you’re a CNC engineer, product designer, or manufacturer, this article will help you understand how bead blasting elevates both the performance and appearance of your parts.

Key Takeaways:

- Bead blasting uses spherical media to clean, smooth, and refine surfaces without altering part dimensions, making it ideal for cosmetic CNC parts.

- Different media types—glass, ceramic, steel, plastic—offer different results, from gentle matte finishing to heavy-duty shot peening for fatigue-strength improvement.

- Proper control of pressure, media size, blast angle, and operator consistency is essential for achieving a uniform, professional finish.

- Bead blasting is widely used across industries, especially electronics (Apple-style matte aluminum), aerospace, medical devices, and 3D-printed part finishing.

1. What is Bead Blasting?

Bead blasting (commonly known as glass bead blasting) is a precise surface finishing process and a type of media blasting. It works by using compressed air or centrifugal force to propel tiny spherical abrasives — typically glass, ceramic, or plastic beads — at high speed onto the surface of a workpiece.

Core Principles:

Mechanical Surface Modification (Peening Effect):

The heart of bead blasting lies in micro-peening. Think of it as the media gently tapping the surface with countless tiny, rounded hammers.

Instead of scratching or cutting the material (like sanding or grinding would), these spherical beads create a uniform pattern of microscopic dimples.

This process actually strengthens the surface by inducing beneficial compressive stresses.

Cleaning and Uniformity:

This process is excellent for cleaning and smoothing. It efficiently removes contaminants like rust, scale, old paint, or heat treatment discoloration.

It also beautifully blends away minor imperfections left from machining, such as tool marks, burrs, or slight inconsistencies, leaving a perfectly uniform base.

The Final Finish:

Most commonly, bead blasting is chosen to create a consistent, non-reflective aesthetic. It gives metals (like aluminum or stainless steel) and even some plastics a smooth, satin or matte texture that feels great to the touch and looks professionally refined.

2. What Are Types of Bead Blasting Media?

The term Bead Blasting specifically means blasting with round, spherical particles. There’s a whole family of these bead media, each with its own personality and best uses — from glass and ceramic to stainless steel and plastic.

2.1. Glass Beads

Glass beads are the all-rounders: cost-effective, versatile, and gentle. With a medium hardness, they’re perfect for cleaning, light deburring, and giving metals like aluminum and stainless steel that smooth, uniform satin or matte finish we often love.

They’re kind to surfaces, reduce the risk of damage, and still offer a mild peening effect. Great for cosmetic finishes and everyday finishing jobs.

2.2. Ceramic Beads

Think of ceramic beads as the tougher, longer-lasting cousins of glass beads. They’re harder and can be recycled many more times.

Ceramic beads work faster and leave a more refined, durable finish — which makes them a go-to for high-performance metals (like titanium and nickel alloys) in aerospace and medical industries, where precision and strength really matter.

2.2. Steel Shot

Steel shot is the heavy lifter of the bead family. These spherical iron-based beads are all about strength and impact.

They’re used for heavy-duty peening — think large castings, structural parts, and removing thick scale or old coatings. Steel shot is incredibly durable (it can be reused thousands of times) and is specially chosen to boost a part’s fatigue life and stress resistance.

2.4. Plastic Media

Plastic beads are the gentle giants. They’re soft and non-abrasive, making them ideal for delicate surfaces like plastics, composites, or sensitive coatings.

Use them when you need to strip paint or clean a part without damaging what’s underneath. They’re also a cleaner, cooler, and more eco-friendly alternative to chemical strippers — no heat, no harsh chemicals, just gentle, effective blasting.

3. Common Grit Sizes (Mesh) in Bead Blasting

In bead blasting, grit size is often labeled using a “Mesh” number — like #60, #80, #100, #120,#150 or #200.

The higher the mesh number, the finer the bead. And finer beads give you a smoother, more satin-like finish.

4. What are the Main Advantages of Bead Blasting?

Bead blasting serves two essential purposes in manufacturing: cosmetic finishing, functional and surface preparation.

4.1. Aesthetic Finishing & Defect Removal

This is the most common — and visually impactful — use of bead blasting in CNC manufacturing.

- Removes CNC Tool Marks

Gently erases the fine, directional lines, scratches, and unevenness left by milling, turning, or grinding — leaving a clean, consistent surface.

- Creates a Uniform Look

Gives metals (like aluminum and stainless steel) and engineered plastics a smooth, non-directional matte or satin finish that elevates the product’s look and feel.

- Deburrs & Softens Edges

Safely removes small burrs and sharp edges after machining, improving part safety and ease of assembly.

- Refines Prototypes & 3D-Printed Parts

Perfect for smoothing the surface of 3D-printed components (like SLS or MJF), making them look closer to injection-molded parts.

4.2. Pretreatment for Coatings

Bead blasting is a crucial step before many high-end surface treatments — it ensures coatings stick better and last longer.

- Enhances Adhesion

Creates a microscopic “anchor profile” on the surface, giving coatings (like anodizing, powder coating, plating, or painting) a stronger mechanical grip and longer life.

- Cleans & Prepares the Surface

Removes heat treatment scale, welding residue, light rust, and other contaminants — ensuring a clean base so coatings go on smoothly and without defects.

- Prepares for Anodizing (Key for Aluminum)

Provides a consistent surface texture before anodizing, which leads to more uniform color and finish on the final part.

5. What Are the Types of Bead Blasting?

5.1. By Media Type

This is the most practical and widely used way to classify bead blasting in the industry:

Glass Bead Blasting: The most common type, ideal for CNC cosmetic parts.

Ceramic Bead Blasting: Higher-end, provides a finer, more precise surface finish.

Plastic Bead Blasting: Extremely gentle, safe for delicate or sensitive parts.

Metal Bead Blasting: For example, stainless steel beads used for shot peening or achieving a polished finish.

5.2. By Operating Method

Depending on the equipment and how the media is applied, bead blasting can be classified as dry or wet:

Dry Bead Blasting:

It is the most common method. Dry media is propelled onto the part using compressed air. Dry bead blasting is suitable for most CNC post-processing, shot peening, and general cleaning tasks.

Wet Bead Blasting (also called Vapor Honing):

Fine media, such as glass or ceramic beads, is mixed with water and anti-rust agents to form a slurry, then sprayed onto the part.

Wet blasting significantly reduces dust, provides a finer and smoother surface finish, and is ideal for precision parts or components with extremely strict surface roughness requirements.

By Automation Level, bead blasting is classified by:

Handheld Bead Blasting:

An operator uses a handheld nozzle inside a closed blasting cabinet to treat parts, suitable for prototypes, small batches, or geometrically complex parts.

Automated Blasting:

Uses turntables, conveyors, or robotic arms for programmed, consistent blasting of large quantities of parts, suitable for medium to large batch production, ensuring surface finish consistency across parts.

5.3. By Purpose

While all bead blasting uses spherical media, it can be further categorized based on its purpose and energy:

Cosmetic / Cleaning Blasting:

Purpose: Mainly for cleaning, deburring, and achieving a uniform matte or satin finish.

Features: Uses relatively fine glass or plastic beads at lower pressure. The main goal is to enhance the appearance, remove CNC tool marks, and leave almost no dimensional change to the substrate.

Shot Peening:

Purpose: An engineering-strengthening process rather than simple surface finishing. It uses high-velocity spherical media (usually steel or ceramic beads) to induce uniform residual compressive stress on the metal surface.

Features: Higher impact energy, with strict control of coverage, intensity (measured using Almen strips), and media size. The goal is to improve fatigue life and resistance to stress-corrosion cracking.

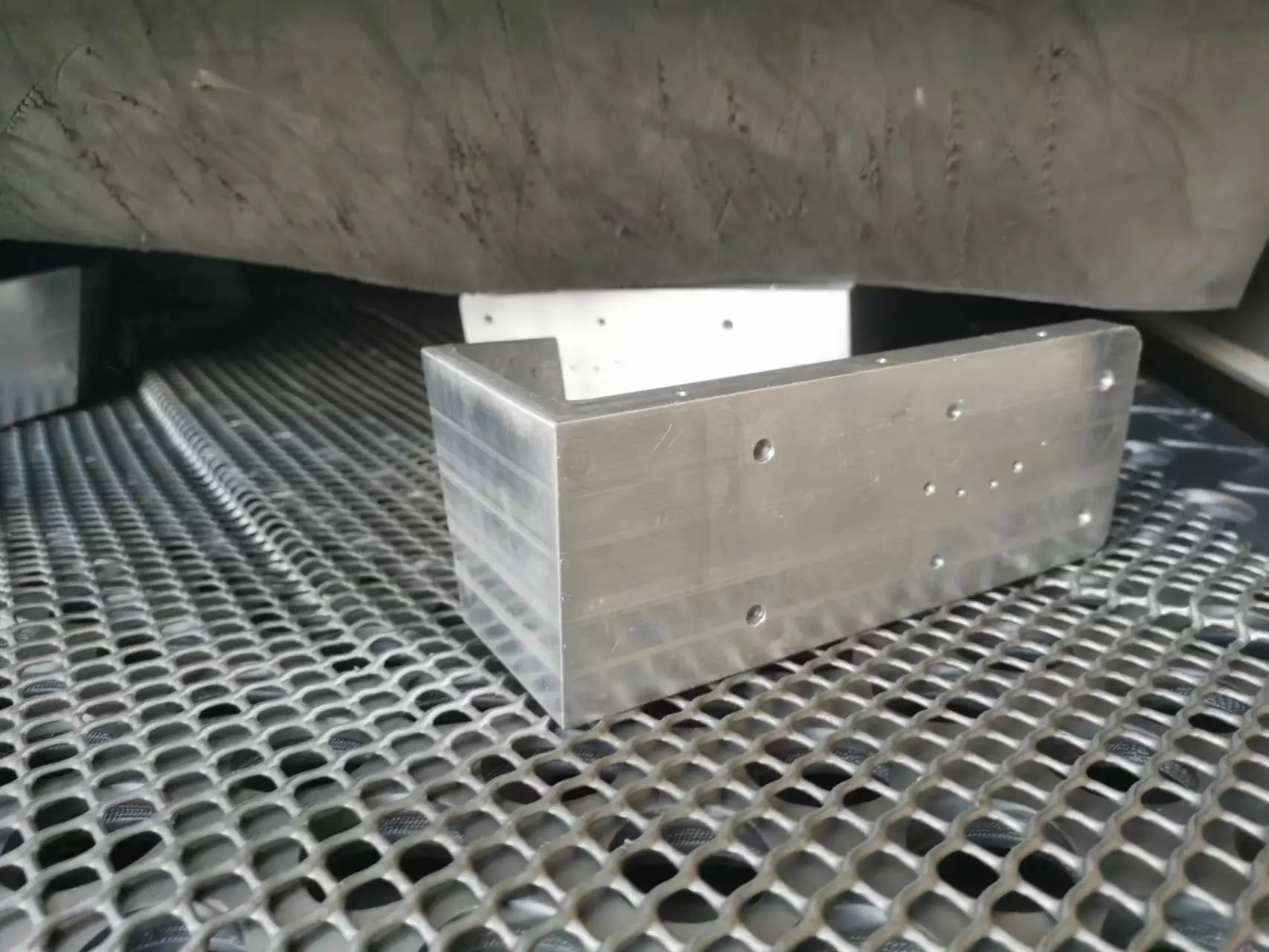

6. How Does Bead Blasting Work?

The working principle of bead blasting is simple but highly effective: spherical media (such as glass beads) are propelled at high speed onto a part’s surface using compressed air, creating uniform microscopic impacts that achieve a matte finish, remove tool marks, or clean the surface.

Here’s how it happens, step by step.

Step 1: Loading & Mixing

The chosen media (glass beads, ceramic beads, etc.) is loaded into a hopper or pressure tank.

In dry blasting, the beads stay dry.

In wet blasting, they’re mixed with water to form a slurry — great for reducing dust and getting an extra-smooth finish.

Step 2: Acceleration & Blasting

This is where the beads get their speed. There are two common systems:

Pressure Blasting (Most Common)

Compressed air is pushed through the system, creating a high-speed stream that sucks the beads into the flow (thanks to the Venturi effect) and shoots them out through a nozzle.

Centrifugal (Wheel) Blasting

A high-speed spinning wheel flings the beads outward using centrifugal force. This method is great for large-scale, consistent processing — like blasting big batches of parts on a conveyor.

Step 3: Surface Impact & What Actually Happens

When those fast-moving beads hit the surface, three things occur almost at once:

Micro-Cutting

Even round beads can knock off contaminants, light rust, or tiny burrs — like a gentle but effective “scrub.”

Plastic Deformation

The impact flattens microscopic peaks on the surface, creating that smooth, uniform matte or satin look — no scratches, just a soft texture.

Surface Activation

The process cleans and exposes fresh material underneath, while also slightly roughening the surface at a microscopic level. This improves adhesion for painting, coating, or bonding later on.

Step 4: Media Recovery & Separation (The Recycling Loop)

In a closed-loop system, the used beads and debris are vacuumed back. They pass through a separator that filters out dust and broken beads, letting the good ones return to the hopper for reuse. This saves material, cuts cost, and keeps things efficient.

Step 5: Dust Collection (Keeping It Clean & Safe)

A good dust collector (like a cartridge filter system) is essential. It captures fine particles created during blasting, keeping the workspace clean, safe, and compliant with health and environmental standards.

7. Which Materials Can Be Bead Blasted?

Bead blasting (glass bead blasting) is suitable for most metal materials and certain plastics.

It’s considered a “gentle” form of blasting, making it ideal for parts with high aesthetic requirements and where dimensional changes must be avoided.

- Aluminum & Aluminum Alloys

Excellent candidate for bead blasting. Bead blasting removes CNC tool marks and provides a consistent satin finish.

It’s a standard pre-treatment step before anodizing, ensuring uniform color and adhesion of the anodized layer.

- Stainless Steel

Used to remove weld discoloration, heat-treatment scale, or light corrosion stains. Creates a uniform matte or polished look, especially popular for medical devices and high-end consumer electronics.

- Titanium & Titanium Alloys

Used to achieve specific medical or aerospace-grade surface finishes. Ceramic beads are often used for shot peening titanium to improve its fatigue life.

- Brass, Bronze & Copper

Great for cleaning, removing tarnish, and creating a uniform satin or antique appearance without damaging the base metal.

- Low/Medium Carbon Steel

Mainly used for shot peening (with steel shot) to enhance structural integrity. Also used for cleaning and surface prep before coating.

- Plastics & Composites

Due to the gentle nature of bead blasting, it can also be applied to many non-metallic materials, especially parts that require surface texturing:

Engineering Plastics:

Includes ABS, PC (polycarbonate), PEEK, Nylon, and others.

Applications: Primarily for cosmetic finishing and removing surface marks on 3D-printed parts (such as SLS or MJF) to achieve a smooth touch and consistent color. Plastic beads or very fine glass beads are typically used to avoid damage.

Fiberglass and Composites:

Applications: Gently removes surface coatings or contaminants, preparing the surface for subsequent painting or coating.

8. What Surface Finish Does Bead Blasting Achieve?

Bead blasting creates a uniform, fine, non-directional matte finish on metal surfaces. It is one of the most popular surface textures for CNC cosmetic parts and is often seen in products from brands like Apple, Dyson, and Tesla.

8.1. Matte Finish

Produces a soft, non-reflective surface that is easy on the eyes.

Not as shiny as polishing, and not as coarse as traditional sandblasting.

8.2. Smooth & Satin-Like

The spherical media leaves a very fine, silky surface feel, such as:

Satin

Soft Matte

Provides a premium tactile sensation, making it standard for high-end cosmetic parts.

8.3. Non-Directional Finish

Unlike brushing or polishing, bead blasting leaves no linear marks.

Ideal for parts that require a consistent, uniform appearance.

8.4. Hides Minor Defects

Bead blasting can mask:

Tool marks

Minor scratches

Machining lines

Slight color variations

This gives parts a more premium and consistent look.

8.5. Uniform Color Appearance

After blasting, metal surfaces appear:

More stable

Cleaner

Visually consistent

This effect is especially noticeable on aluminum, significantly enhancing its aesthetic appeal.

8.6. Popular Visual Effects (Reference)

Bead blasted aluminium: Silver-gray matte, soft misty finish

Bead blast stainless steel texture: Soft, bright matte

Titanium: Dark gray matte, highly premium appearance

9. Which Industries Use Bead Blasting?

Bead blasting is widely used in high-end appearance parts, functional cleaning, surface modification, and process pretreatment.

Due to its gentle nature, minimal dimensional impact, and premium finish, it’s particularly popular in the CNC machining industry.

9.1. High-End Consumer Electronics

This is one of the most prominent applications, especially for premium products where look and feel matter.

Examples include:

MacBook enclosures

Internal aluminum components of iPhones

Camera housings

High-end audio equipment cases

Key benefits: Creates a uniform matte finish with a silky-smooth touch, elevating perceived quality and user experience.

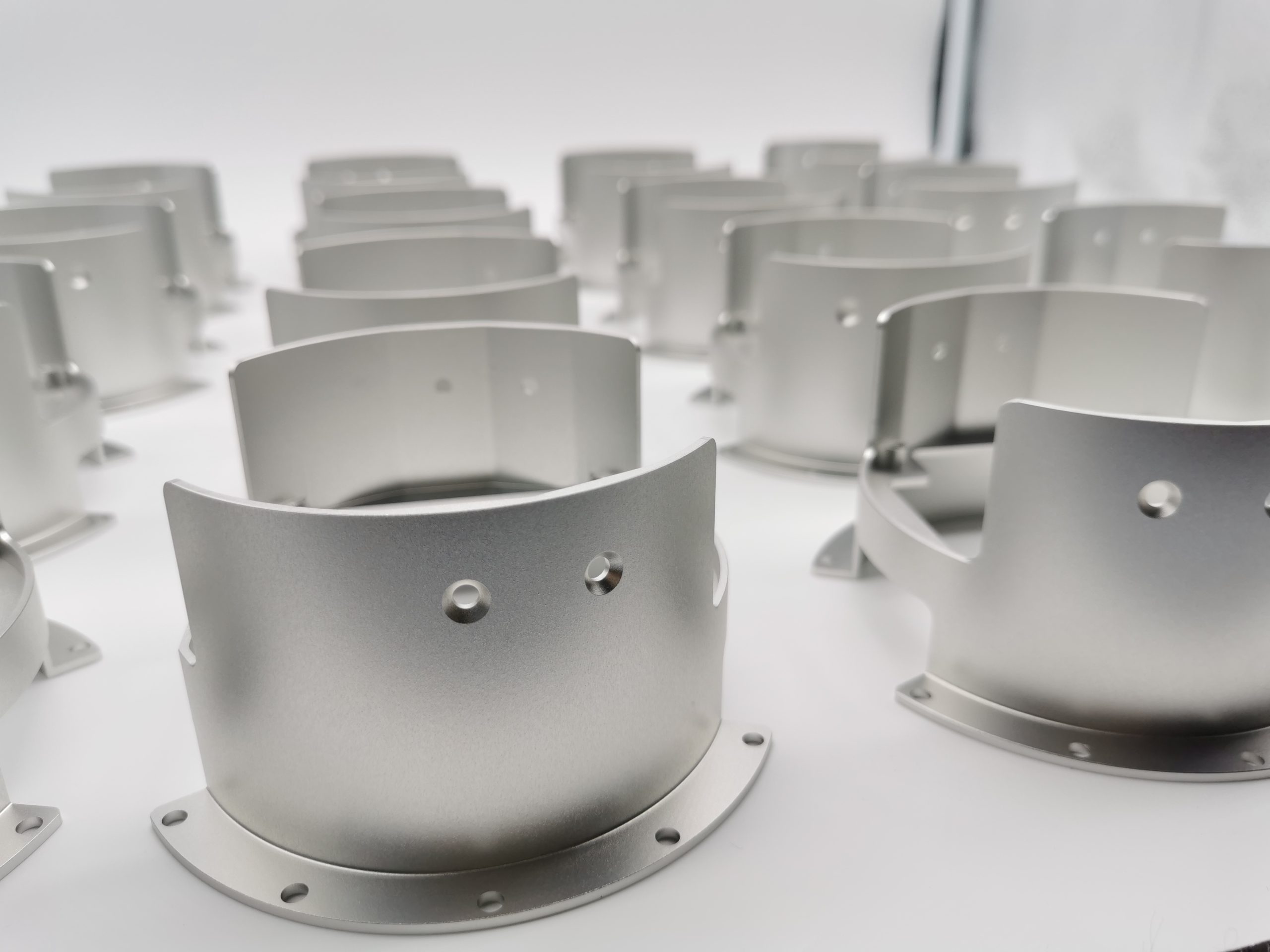

9.2. CNC Aluminum Exterior Finishing

This is one of the largest application areas for bead blasting, especially for CNC-machined parts.

Common uses:

Appearance covers and housings

Industrial design shells

Instrument and control panels

Heat sink covers

Why it works: Significantly improves visual appeal while masking machining marks and scratches.

9.3. Medical Devices

Medical equipment requires surfaces that are visually clean, non-reflective, and easy to sanitize.

Typical applications:

Titanium alloy enclosures

Stainless steel surgical tools

Medical instrument housings

Added value: Creates a soft, glare-free finish that enhances both aesthetics and hygiene.

9.4. Aerospace & Aviation

Bead blasting serves both functional and aesthetic roles in aerospace components.

It is used for:

Removing heat treatment discoloration

Light stress relief (mild peening)

Surface cleaning and degreasing

Achieving visual consistency

Ideal for: Titanium and aluminum structural parts, where precision and surface integrity are critical.

9.5. Automotive Industry

Adds a premium, understated look to both interior and exterior metal components.

Often applied to:

Interior trim pieces

Dashboard and instrument housings

Decorative aluminum accents

Custom aftermarket parts

Result: A refined, matte appearance that stands out without being flashy.

9.6. Stainless Steel & Titanium Part Cleaning

A non-destructive way to restore and clean sensitive metal surfaces.

Effectively removes:

Weld discoloration

Heat treatment scale

Surface contaminants

Advantage: Cleans thoroughly without altering part dimensions or damaging the base material.

9.7. Post-Processing for 3D Printed Parts

Helps achieve a smoother, more uniform surface on additive-manufactured components.

Commonly used for:

SLM metal prints (aluminum, stainless steel, titanium)

SLA resin parts (with gentle blasting)

Purpose: Reduces layer lines and improves visual consistency, making prints look more like finished products.

9.8. Pre-Coating & Pre-Anodizing Preparation

Creates an ideal surface for subsequent coatings to adhere strongly and evenly.

Improves:

Color consistency in anodizing

Adhesion in powder coating

Quality of plating results

Note: Nearly all aluminum parts destined for anodizing are bead blasted first for a uniform base.

9.9. Industrial Equipment Housings

Elevates the appearance of functional industrial products.

Applied to:

Instrument and gauge enclosures

Control boxes and industrial housings

Surveillance and monitoring device shells

Benefit: Makes equipment look more professional, durable, and high-end, enhancing brand perception.

10. How to Achieve a Good Bead Blasting Finish?

To achieve a high quality bead blasting finish, precise control over media, equipment parameters, part preparation, and operating technique is essential.

10.1. Media Selection and Maintenance

Choose the right media

Glass beads – standard satin finish, versatile for most metals.

Ceramic beads – finer, longer lasting finish with stronger peening effect.

Plastic beads – gentle treatment for sensitive materials.

Control particle size (Mesh)

Finer media → smoother finish (e.g., 50–150 µm for fine, 150–300 µm for medium, >300 µm for coarse).

Conduct batch size checks to ensure consistency.

Maintain and replace media

Recycle usable beads and remove broken ones/dust via a good separation system.

Establish a regular media replacement schedule to prevent worn out beads from degrading finish quality.

10.2. Pre-treatment and Part Preparation

Clean thoroughly – remove all oil, grease, and contaminants to avoid blotchy results.

Mask critical areas – use tape, plugs, or fixtures to protect threads, holes, and tolerance zones.

Remove major burrs first – bead blasting is best for light deburring, not heavy material removal.

10.3. Equipment Parameter Control

Blasting pressure – adjust according to material hardness and media type; too high causes orange peeling, while too low results in an incomplete texture.

Nozzle to part distance – keep consistent (usually 100–300 mm); too far reduces impact, too close causes over treatment.

Blast angle – typically near 90° for even peening; adjust for hard-to-reach areas.

Exposure time – maintain steady speed and overlap (30–50%) for uniform coverage.

10.4. Operating Technique and Consistency

Move steadily – use overlapping passes to ensure 100% coverage without pauses.

Automate when possible – turntables or robotic systems ensure repeatability for high-volume or large batches.

Train operators – standardize gun movement patterns and emphasize consistency.

Quick Tips for a Great Finish

✅ Start with a test piece – dial in settings on a sample first.

✅ Keep media fresh – screen out fines and replace worn beads regularly.

✅ Mask thoroughly – protect what you don’t want blasted.

✅ Clean immediately after blasting – prevent media residue from settling.

✅ Document your process – note media type, pressure, time, and distance for repeatable results.

11. Summary

Bead blasting is one of the most effective and versatile surface-finishing processes used in modern CNC machining, manufacturing, aerospace, medical devices, and consumer electronics.

By propelling spherical media—such as glass, ceramic, plastic beads, or steel shot—onto the surface, it creates a uniform matte finish, removes tool marks, enhances coating adhesion, and improves the overall appearance and performance of parts.

With the right media selection, controlled blasting parameters, and consistent operator technique, manufacturers can achieve a premium, repeatable finish that meets both aesthetic and functional requirements.

Lucas is a technical writer at ECOREPRAP. He has eight years of CNC programming and operating experience, including five-axis programming. He’s a lifelong learner who loves sharing his expertise.

Other Articles You Might Enjoy

What is 5-axis Machining? A Complete Guide.

5-Axis CNC machining is a manufacturing process that uses computer numerical control systems to operate 5-axis CNC machines capable of moving a cutting tool or a workpiece along five distinct axes simultaneously.

Which Country is Best for CNC Machining?

China is the best country for CNC machining service considering cost, precision, logistic and other factors. Statistical data suggests that China emerges as the premier destination for CNC machining.

Top 5 Prototype Manufacturing China

Selecting the right prototype manufacturing supplier in China is a critical decision that can significantly impact the success of your product development project.

CNC Machining Tolerances Guide

Machining tolerances stand for the precision of manufacturing processes and products. The lower the values of machining tolerances are, the higher the accuracy level would be.