- Capabilities

-

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

Acetal vs Delrin: What is the difference?

Updated: Jan.26, 2024

Acetal and Delrin are terms often used interchangeably, what is their difference? The main difference is that Delrin may have centerline porosity. After reading this article, you will get more understanding of their differences.

1. What is Acetal?

Acetal is the common name for a thermoplastics family, whose chemical name is PolyOxyMethylene, for short, POM. From its definition, we can say Acetal and POM refer to the same product group. In simple, they are the same, the only difference between Acetal and POM is that one is a common name, and one is a chemical name.

There are two general types of Acetal resin: Copolymer acetal (POM-C), and homopolymer acetal (POM-H).

2. What is Delrin?

Delrin is a trademarked name for DuPont’s polyformaldehyde products and is commonly used to refer to POM-H type polyformaldehyde. Thus, Delrin is a specific trademark for POM.

3. Acetal VS Delrin

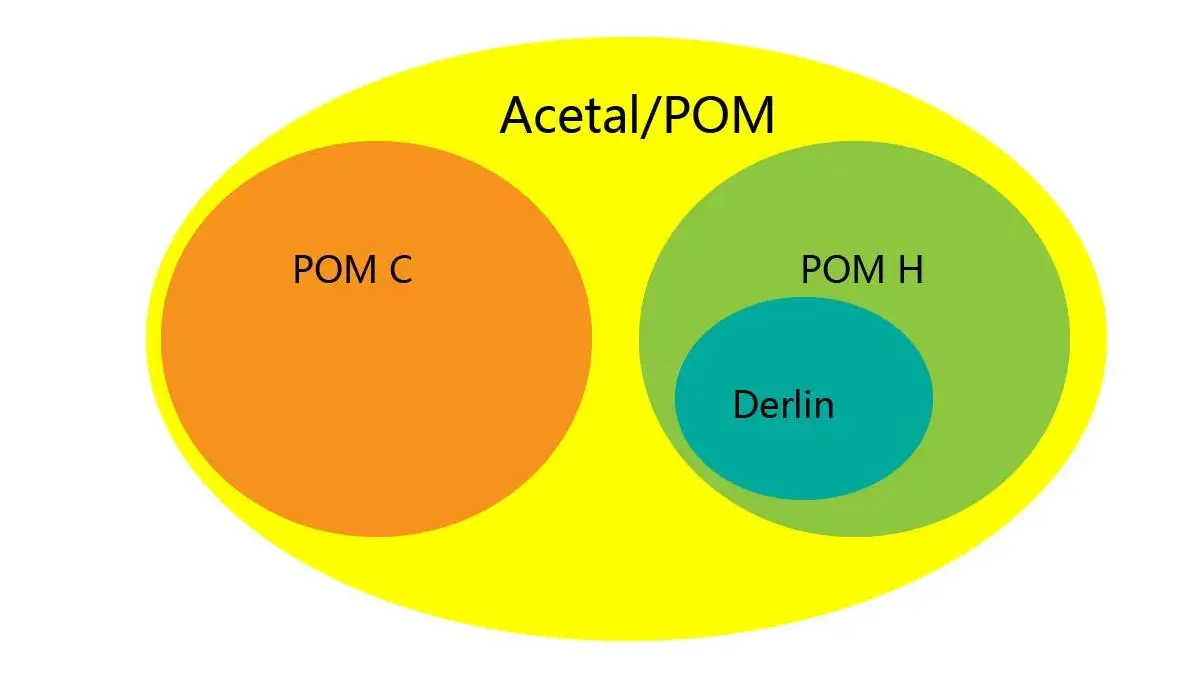

Acetal vs Delrin is the same meaning as POM vs Delrin. For the drawing below, we can see clearly about the relation about Acetal and Delrin.

In general, Delrin, Acetal, and POM are all used to refer to the category of Polyoxymethylene materials.

4. What is Acetal Copolymer?

Each type of Acetal has its advantages and disadvantages.

Compared with POM H, Acetal copolymer offers excellent performance at a cheaper cost. Acetal copolymer offers consistent shape properties, low stress, and high strength. The above properties can assure Acetal copolymer flatness and dimensional stability stability up to a maximum continuous service temperature of 180°F (80°C).

There are different grades of copolymer acetal, including USDA, FAS, NSF and 3-A Dairy compliant. Rich colors are available in acetal copolymer, for example, natural, black, red, blue, and others. Check with us for other color requirements.

Other advantages over homopolymer acetal are:

Better dimensional stability due to its lower level of crystallization.

Better resistance to strong caustics and hot water, or high PH solutions.

Reduced frictional resistance, along with enhanced impact and wear resistance, particularly in damp or humid conditions.

5. What is Acetal Homopolymer?

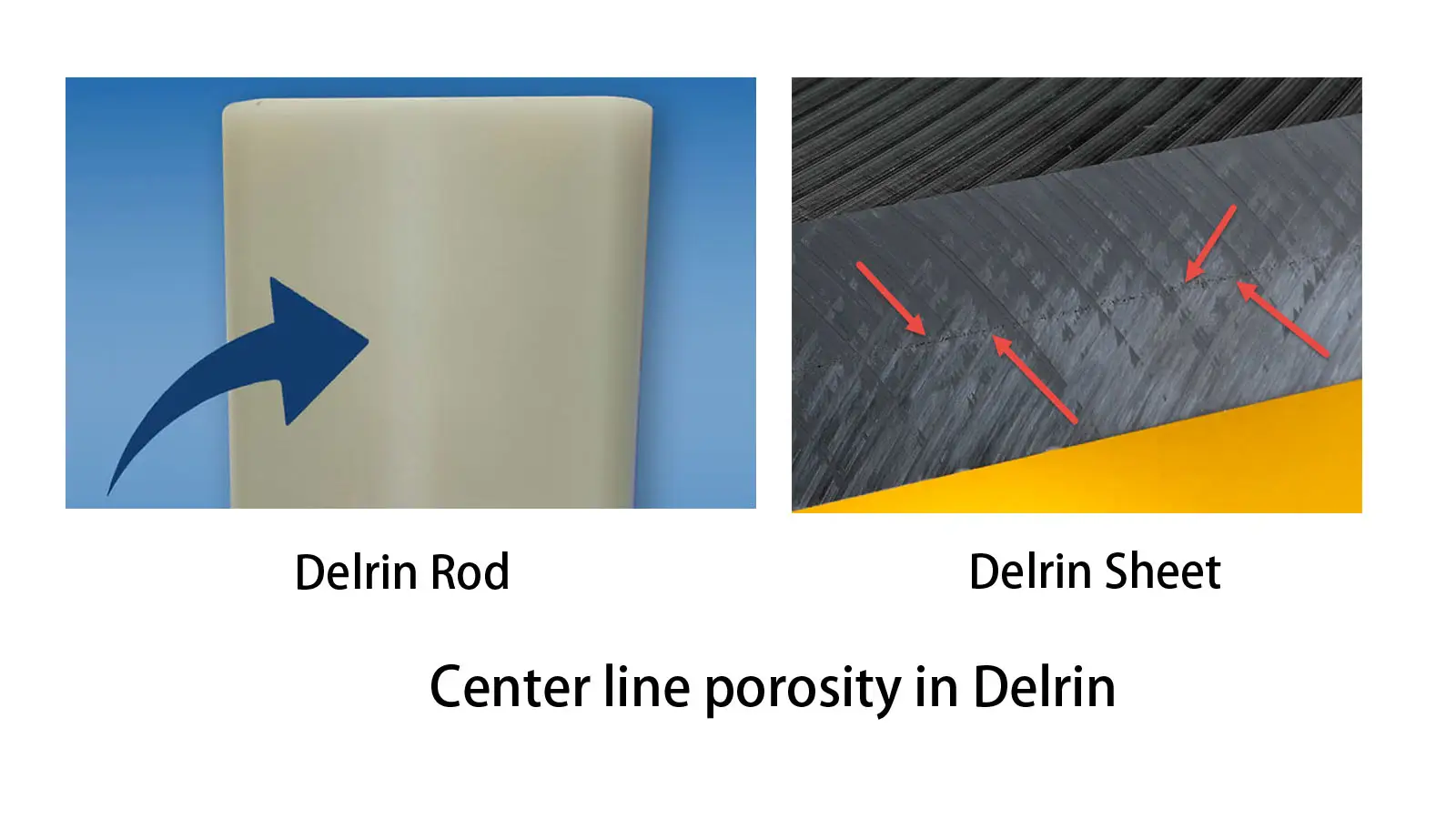

Compared with acetal copolymer, Acetal homopolymer has slightly higher mechanical properties. Acetal homopolymer has a low-density center(center line porosity). It happens especially to large cross-sections.

However, acetal copolymer offers consistent properties throughout the shape (being free of centerline porosity).

Delrin is less chemical resistance than copolymer acetal. Thanks to Delrin’s additional strength and rigidity, it is an ideal material for small-diameter and thin-walled bushings. Usually, Delrin is available in natural and black.

Other advantages over copolymer acetal are:

Greater stiffness, with a higher flexural modulus for use in both regular and high-temperature conditions.

Slightly higher tensile and impact strength at room and lower temperatures .

Slightly harder, thus giving the homopolymer acetal a lower coefficient of friction.

6. What is the difference between Acetal copolymer and Acetal Homopolymer?

In most applications, Delrin and acetal copolymer can be interchanged because many material properties are within approximately 10% of each other.

Notably, the most significant difference between Delrin and copolymer acetal relates to what is commonly known as centerline porosity – an inherent characteristic of Delrin.

Porosity is most prominent in thick slabs and large-diameter rod stock. It is maybe clearly evident around the center portion of a rod, which may extend down to the entire length.

In sheet form, porosity manifests as a line along the center of each cut edge. In certain instances, the slab may exhibit a laminated or bonded appearance.

The excessive centerline porosity is undesirable for many reasons:

Less aesthetic – inconsistent color appearance in CNC machined finished parts.

Compromises structural integrity.

Potential leakage of gas and liquids.

Provides space for the bacteria which can grow in food processing applications.

How does the porosity happen? The cause is shrinkage. The outside of the shape cools faster than the interior during the extrusion process. As the interior material undergoes cooling, there is a simultaneous decrease in volume. The solidified outer layer constrains the overall shape from undergoing significant volume changes. Consequently, voids develop to offset the reduction in interior volume.

7. Summary

There is no big difference between Delrin and Acetal as the main properties are almost the same, except that Delrin has the possibility of centerline porosity.

At ECOREPRAP, we provide Delrin production in both natural and black colors. There are some special considerations that shall be taken into consideration. Read our blog Mastering CNC Machining Delrin: In-Depth Guide to learn more.

Let's get your projects started, together!

Get custom parts machined in high quality, delivery on time.