Basic Introduction of Polyurethane Materials

Updated: Mar. 13, 2024

Polyurethane is a comprehensive performance material with many outstanding properties. In this article, we will introduce its definition, properties and applications.

1. What is PU material?

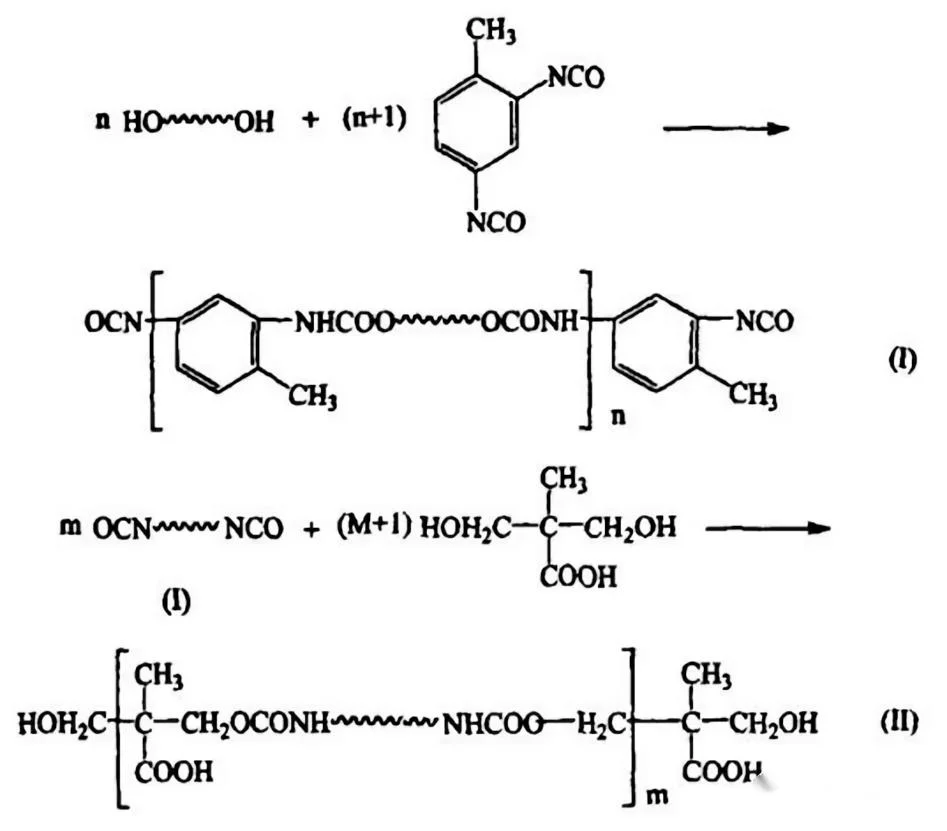

Polyurethane is a polymer containing urethane group (-NHCOO) in the main chain of polymer, the full name of polyurethane or isocyanate polymers. The abbreviation is PU.

Polyurethane is a type of elastomer that falls between plastic and rubber, offering a comprehensive set of properties that are distinct from ordinary plastic and rubber. It is considered an emerging organic polymer material and is often referred to as the “fifth major plastic.”

Polyurethane elastomers exhibit excellent characteristics such as abrasion resistance, chemical resistance, tensile strength, high elasticity, resistance to high-pressure loads, superior abrasion resistance, effective shock absorption, tear resistance, resistance to radiation, high overall strength, and the ability to bear high loads while providing shock absorption and cushioning. Simultaneously, polyurethane elastomers come in a broad range of hardness, ranging from Shore A10 to A100, and there are currently products available with hardness exceeding Shore A100.

Because of its excellent performance and is widely used in many areas of the national economy, such as light industry, chemical industry, electronics, textiles, medical, construction, building materials, automotive, national defense, aerospace, aviation and so on.

Polyurethane is formed by polyisocyanate and polyhydroxy polymer polymerization. It is a polymer compound containing many repeating urethane chain segments (-NHCOO-) on the polymer main chain.

Polyurethane is a variety of polymer materials in the only one in the field of plastics, rubber, foam, fibers, coatings, adhesives and functional polymers have significant applications in the field of synthetic polymer materials, products penetrate into all aspects of the national economy, has become the current polymer materials in the most varieties, the most widely used, the fastest growing special organic synthetic materials.

2. History of polyurethane materials

In the 1930s, German scientists first synthesized polyurethane, but due to the limited technical level at that time, polyurethane was not widely used.

Until the 1950s, with the continuous improvement of synthesis technology, polyurethane began to be widely used in construction, automobile, furniture and other fields. In the 1960s, polyurethane foam began to be widely used in building insulation.

In the 1970s, polyurethane materials began to be used in shoe-making and packaging. At the same time, polyurethane elastomer materials also began to be widely used.

In the 1980s, the application fields of polyurethane materials were further expanded, and began to be used in aerospace, electronics, medical and other fields.

After the 1990s, with the increasing awareness of environmental protection, the environmental protection of polyurethane materials was also emphasized, and more environmentally friendly polyurethane materials began to be developed.

In the 21st century, the application fields of polyurethane materials have further expanded, and at the same time, technological innovations are constantly being made to develop more high-performance and environmentally friendly polyurethane materials.

3. Characteristics of PU materials

3.1 Reactability: polyurethane is a polymer made by reacting isocyanate and polyol, so it has reactability.

3.2 Softness and hardness adjustability: the hardness of PU can be adjusted by adjusting the ratio of isocyanate and polyol. From Shore A10-100, higher hardness PU can be used for CNC machining.

3.3 Abrasion resistance: Polyurethane has good abrasion resistance and is suitable for applications requiring abrasion resistance, such as shoe soles and tires. Abrasion resistance is 3 to 5 times that of general rubber. Scratch-resistant, no noise, long service life, low cost, polyurethane materials have excellent abrasion resistance and flexibility. Such as for shock absorbers, for buffer blocks, and couplings, there are many for the silk rod assembly shock absorbing buffer role of the paste block.

3.4 Oil resistance: polyurethane has good oil resistance, applicable to the need for oil resistance occasions, such as oil pipes, oil seals.

3.5 Cold resistance: polyurethane has good cold resistance, suitable for occasions requiring use at low temperatures, such as cold storage equipment. The temperature resistance is -40℃~120℃.

3.6 Aging resistance: polyurethane has good aging resistance and is suitable for occasions requiring long-term use, such as construction materials. Resistant to various organic and inorganic acids and alkalis, amines, salts and solvents.

3.7 PU is a new type of material between plastic and rubber, with the rigidity of plastic and the elasticity of rubber. Therefore, it is often used in parts with a certain degree of elasticity and rigidity.

4. Classification of polyurethane

Polyurethane is widely used in many fields of the national economy because of its excellent performance, and the product application involves light industry, chemical industry, electronics, textile, medical care, construction, building materials, automobile, national defense, aerospace and aviation. The application of polyurethane is mainly divided into three major aspects: polyurethane flexible foam, polyurethane rigid foam and polyurethane elastomer.

4.1 Polyurethane soft foam

Polyurethane soft foam is a very ideal cushioning material, which is also the largest amount of soft foam applications. Open-cell polyurethane soft foam has a good acoustic dissipation function, and can be used as an indoor soundproofing material; fabric composites: shoulder pads, bra sponges, cosmetic cotton.

4.2 Polyurethane rigid foam

Polyurethane rigid foam stands out as the optimal insulation material for freezing and refrigerating equipment, delivering superior thermal insulation efficiency. It can be used as refrigerators, freezers, insulation boxes, heaters and other electrical appliances insulation insulation layer.

Polyurethane rigid foam can be used as storage tanks, pipeline insulation materials, in the petroleum, chemical, natural gas and other industries are widely used.

PU rigid foam can be used for automobile roof, interior parts and many kinds of automobile parts, such as door panels, luggage compartment covers, engine covers, etc.

High-density (density of 300~700kg/m3) PU rigid foam or glass fiber reinforced rigid foam is structural foam, also known as wood-like material. It can be applied in profiles, plates, sporting goods, decorative materials, etc.

4.3 Polyurethane elastomer

Polyurethane elastomer include cast polyurethane elastomer (CPU), thermoplastic polyurethane elastomer (TPU) and compounded polyurethane elastomer (MPU). Polyurethane elastomer are used in machinery parts, rollers, conveyor belts, seals, rollers and tires. They can also be used to make elastic fibers, synthetic leather resins, adhesives and coatings.

Polyurethane elastomers owns excellent tensile strength, tear resistance, impact resistance, abrasion resistance, weather resistance, hydrolysis resistance, and oil resistance, among other advantages. It is mainly used as coating materials (e.g. protection of hoses, gaskets, wheel belts, rollers, gears, pipes, etc.), insulators, shoe soles and solid tires.

PU used for CNC machining belongs to elastomer with medium or harder hardness. The hardness is above 60A.

4.4 Polyurethane coatings

Polyurethane coatings have strong adhesive properties, and the coating film has excellent abrasion resistance, water resistance and drug resistance. It is primarily employed for coatings in furniture, building materials, and industrial printing inks.

4.5 Polyurethane fiber

The high resilience of polyurethane fiber (spandex for short) is incomparable to all elastic fibers. In traditional textiles, only less than 5% quantity of spandex needs to be added to make the grade of traditional fabrics greatly improved, showing a soft, comfortable, beautiful and elegant style.

4.6 Polyurethane shoe

Polyurethane shoe soles made of original liquid have low density, soft texture, comfortable wearing, good wear-resistant, shock-absorbing and non-slip performance, and are mostly used in the manufacture of high-grade leather shoes, sports shoes and traveling shoes.

4.7 Polyurethane adhesive

Polyurethane adhesive’s low-temperature and ultra-low-temperature performance exceeds that of all other types of adhesives, and it is mainly used in packaging, construction, timber, automobile, shoe-making and other industries.

4.8 Polyurethane sealant

Polyurethane sealant is a material used to fill voids (holes, joints, seams, etc.), both bonding and sealing two functions. Polyurethane sealant, silicone sealant, and polysulfide sealant make up the three primary categories of high-grade sealants.

4.9 Polyurethane waterproof material

Polyurethane waterproof material is quite convenient to use, can be mixed at the scene, coated with room temperature curing, can be obtained with no seams, rubber elasticity and has good performance of the waterproof layer, and easy to repair after damage. Generally used as paving materials, track and field track materials, racecourse, park ground materials, heat insulation window frames and so on.

4.10 Polyurethane adhesive

By adjusting the ratio of isocyanate and polyalcohol to realize the adjustment of curing material performance, polyurethane can achieve a high degree of adhesion to the substrate, excellent water resistance, oil resistance and chemical resistance. It is mainly used in the fields of packaging, construction, wood, automobile and shoe-making.

4.11 Biomedical Materials

Polyurethane exhibits outstanding biocompatibility, leading to its increasing adoption as a biomedical material. It can be used to manufacture artificial pacemakers, artificial blood vessels, artificial bones, artificial esophagus, artificial kidneys, artificial dialysis membranes and so on.

5. Common application industries of polyurethane

Building materials: polyurethane can be used to manufacture thermal insulation materials, sound insulation materials, waterproof materials and so on.

Furniture manufacturing: polyurethane can be used to manufacture sofas, mattresses, seats and other furniture.

Automobile manufacturing: polyurethane can be used to manufacture automobile seats, interiors, tires and so on.

Packaging materials: polyurethane can be used to manufacture foam boxes, foam packaging, etc.

Shoe Manufacturing: Polyurethane can be used to manufacture shoe soles, insoles, etc.

Electronic products: polyurethane can be used to manufacture electronic product shells, seals, etc.

Medical Devices: Polyurethane can be used to manufacture handles, cushions, etc. for medical devices.

Aerospace: Polyurethane can be used to manufacture seals, insulation materials, etc. in the aerospace field.