Types of sheet metals how to choose in rapid prototyping

Updated: Apr. 26, 2024

Swift design and creation of physical prototypes or models based on CAD data is what Rapid Prototyping is all about.

It makes testing designs easy and initial validation of designs possible. As a result, the product development cycle is faster and costs are saved.

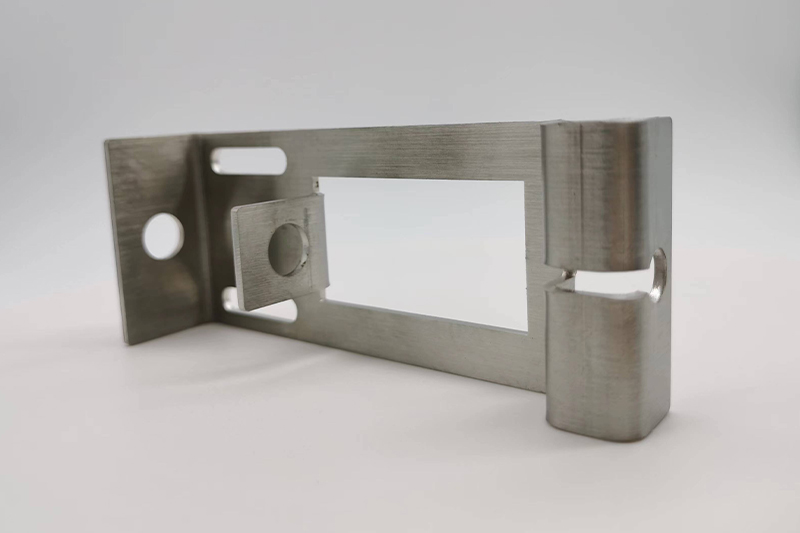

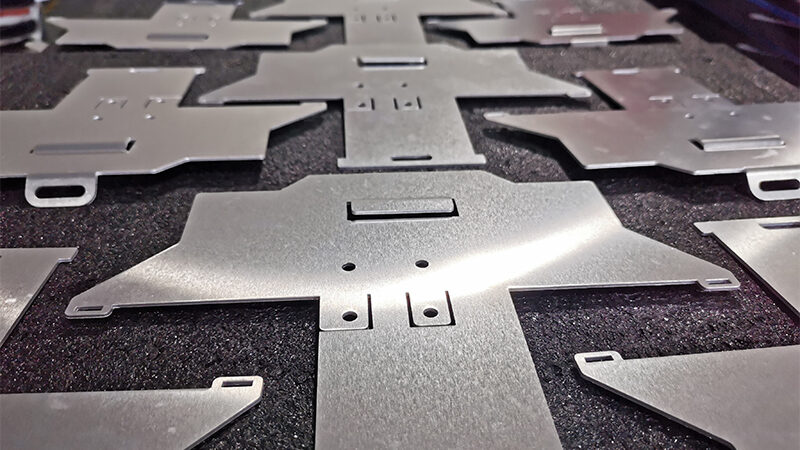

In rapid prototyping, sheet metal is crucial for projects requiring metal components or housings. It has excellent properties such as strength, durability, and ease of fabrication. This allows the production of fully functional prototypes extremely similar to the final product.

Search intent reveals that people wish to learn about the different types of sheet metal often used in rapid prototyping applications. What they need is information on the properties, benefits and disadvantages of different sheet metal materials to help them make educated decisions about their projects.

1. Common types of sheet metals used in rapid prototyping

To provide more valuable content, let’s take a closer look at each type of sheet metal that is used in rapid prototyping:

Aluminium sheet metal for prototyping

The main strengths of Aluminium include the fact that it is lightweight. Since it also has a low density, the material is suitable for applications that require reduced weight. This material offers an outstanding resistance to corrosion, largely due to the formation of a naturally protecting oxide layer.

Furthermore, Aluminium is a material with high conductivity of electricity and thermal energy.

As such, the material is commonly used for conducting thermal energy. Its lightweight, abundance, and versatility make this material widely applicable in virtually any industry and industrial domain, including but not limited to the automotive, aerospace, and electronics sectors.

The reasons why Aluminium is an excellent material for rapid prototyping of the part that is required include the fact that the material is easy to machine.

Additionally, Aluminium can also easily undergo drilling and forming processes, allowing for the fabrication of complex shapes. Lastly, it is also relatively low in cost compared to other metals, rendering it a fitting choice for prototype situations.

On the other hand, its relatively low strength means that the material may not be as strong as steel or titanium. Finally, the surface finish of the created part may also require further finish processes, such as anodising or painting.

The choice of the correct alloy is dependent on the specific requirements of the part. As such, when selecting an optimal alloy, it is essential to consider interface pretreatments when applying a secondary finish. In addition, it is also important to account for how basic factors, such as corrosion resistance, strength, ductility, and hardness.

Stainless steel sheet metal for prototyping

As it displays high corrosion resistance, stainless steel is exceptionally reliable in applications where the material is subjected to tough conditions.

As a result of its great tensile and yield strength, this metal provides not only structural functionality but also longevity. The substance can be attributed to corrosion-resistant materials, as it is also easy to clean due to these reasons a metal to the needs.

I chose stainless steel for a few reasons.

When something is in use for an extended amount of time, brushing is that seven of the. This ability is also a result of the substance’s extra longevity. The substance would be an excellent decision in the case of something like cleansers or other medical instruments and solutions, as stainless steel can reliably withstand high temperatures and sterilization processes.

Finally, stainless steel is a material used in architecture and interiors, as it features a uniquely modern appearance.

However, there are several limitations related to the chosen than that must be noted.

I think steel is expensive, but that is not the only issue. The downside of using stainless steel lies in its machine-crafting complications. limited usability is a result of the fact that despite its popularity substance is one that is tough to machine solutions.

Finally, I also know from experience that some types of steel can be magnetized.

Titanium sheet metal for prototyping

Additionally, titanium has an exceptional strength-to-weight ratio, where the metal is strong while at the same time being very lightweight. This property makes it suitable to be used in manufacturing components where high strength and durability require low weight.

During the same aggressive corrosion environments, titanium corrosion resistance is exceptional. Titanium is non-toxic and biocompatible; therefore, it is widely used in surgical equipment and medical implants.

Titanium is extensively used in aerospace applications due to its strength and resistance to corrosion. It is dry due to its biocompatibility and strength, and as a result, titanium is widely used in medical implants prosthetics and surgical equipment.

Titanium is used to make bicycles, golf clubs, and lawn rackets since it is very light. Titanium is a costly metal compared to other metals hence limiting its usage in money-making procedures. The manufacture of titanium uses sophisticated machinery, and with the high prices obtained, it is costly to cut.

The cutting of titanium materials results in excessive waste products. This increases the production costs and results in environmental pollution.

Brass sheet metal for prototyping

There are many applications for brass, such as decorative applications and electrical components, due to its aesthetic appeal and corrosion resistance.

Copper sheet metal for prototyping

Copper has excellent electrical conductivity and thermal conductivity, so it’s great for electrical and heat transfers.

Carbon Steel sheet metal for prototyping

In the field of structural components and machinery parts, carbon steel is known for its high strength and durability, which makes it a suitable material for structural components.

If we were to elaborate on each of these points, we would be able to provide users with a better understanding of the properties, advantages, and limitations of different types of sheet metal used in rapid prototyping applications.

2. Factors to consider when choosing sheet metals for rapid prototyping

Consider these factors when selecting sheet metal for rapid prototyping:

A. Strength and Durability Requirements

Prototype strength and durability requirements: Its specific strength and durability requirements should be determined according to the intended use. Repairs are based on functionality. Loadbearing, crash resistance, and stalwartness are all factors to consider.

Select sheet metal materials: Choose a sheet metal material that can withstand the stresses of operation and environmental conditions. Try out prototypes. To make sure that prototypes meet strength and endurance standards, use simulation tools and physical tests to see how materials perform elsewhere.

B. Machinability and Formability

Machinability: Sheet metal material The Machinability of the material should be examined, taking into account factors such as its cutting and drilling performance. To reduce time-free production costs that can quickly range (according to materials) for now choose items that are easy to process.

Shape Test Materials are examined to see if they can be deformed into complex forms or not. Materials that bend and powder during stamping should be chosen.

The surface finish of the prototype should be considered. Selecting sheet metals with the finish you desire according to how they can be machined and post-processed.

C. Cost Considerations

Material cost: Determine the cost of sheet metal materials, including raw materials and processing costs. Only compare the costs of different materials once that will not compromise performance or quality as you choose the cheapest option.

When fabricating sheet metal, take into account additional production costs such as machining, tooling, finishing and waste disposal. In other words, while maintaining quality and efficiency you should keep production costs to a minimum.

Calculate life-cycle costs for a prototype, including maintenance, repairs and replacements. Sheet metal should be selected according to its long-term value and initial cost.

D. Compatibility with Rapid Prototyping Techniques

Processing responsibility in laser cutting, and rapid prototyping processes such as CNC machining and additive manufacturing should be evaluated for compatibility with the sheet metal material that is chosen. By selecting materials that can be processed efficiently, these techniques can accelerate prototype development.

Get sheet metal that can be cut, drilled and machined to the desired dimensions easily depending on the prototype’s thickness needs. Rapid prototyping equipment and tooling must be compatible.

Consider the precision and accuracy of the prototype. Choose materials that can be machined with high precision to meet these specifications.

E. Environmental and Regulatory Considerations

Environmental Impact: Consider how sourcing, production, and disposal affect the environmental impact of sheet metal material. Sustainable prototyping practices require materials that make very little impact on the environment and can be recycled.

Adhere to specific regulatory standards and regulations regarding materials when working with The material’s toxicity, emissions, and workplace safety rules should be well understood.

Check the quality certification of sheet metal material ISO certification, ASTM standard, and RoHS compliant are some standards that can be inspected. Choose a single honey supplier to achieve quality and supply continuity.

3. Decision-making process for selecting sheet metals

The decision-making process involved in selecting the most appropriate sheet metal for rapid prototyping comprises the following steps:

Assessment of project requirements and constraints. Identify the prototype’s functional needs, such as the mechanical properties and tolerance, and the optimal environmental conditions.

The required sheet metal should meet certain performance requirements, including strength, durability, conductivity, and resistance to corrosion. Moreover, multiple constraints influence the selection of the material.

These constraints include the budget, timelines, and regulatory requirements that must be complied with.

Finally, consider the opinions of project stakeholders, such as the design and production team, product developers, and end users, to ensure the material aligns with all expectations.

Conducting material research and analysis. Develop a buyer persona representing the ideal sheet metal, considering the mechanical and environmental factors and the chemical composition.

Conduct market research on a variety of sheet metals available, including aluminum alloys, stainless steel grades, and titanium, among others.

Review material data sheets and technical design sheets for all applicable options and match them based on the current needs and constraints given optimal characteristics.

Consulting with engineers and materials specialists.

Consider collaborating with experienced engineers, materials specialists, and metallurgists with experience working with sheet metal in integrated technology.

Collaborate with sheet metal manufacturers and suppliers to gain insights into the material, processes, and cost-effective solutions. Prototyping and testing validation.

Develop prototypes to evaluate the sheet metal provenance’s performance, functionality requirements, and manufacturability.

Validate material selection with this prototyping and identify any potential issues in performance, such as the developed design challenges and simulation performance.

Optimize the selection of sheet metal to ensure the final option works best in full-scale production.

This entire process allows the stakeholders to make informed decisions when developing sheet metal for rapid prototyping projects to optimize prototype performance, regulation, and budget compliance.

4. What are the applications of fabrication work?

Metal fabrication plays a widespread role across diverse fields, demonstrating its adaptability and significance in present-day production. Notable uses include:

4.1. The automotive industry

Metal fabrication is integral to vehicle body parts like frames, panels, and brackets. Vehicles require sturdiness, security, and dependability which advanced fabrication techniques guarantee.

Metal segments are utilized in exhaust frameworks including channels, silencers, and catalytic converters. Precision fabrication ensures optimal functionality and emission compliance.

4.2. The aerospace sector:

Metal fabrication plays a pivotal part in the creation of plane structures including fuselages, wings, tails, and landing rigging. Thanks to aerospace-grade materials and exact fabrication strategies parts are lightweight yet tough.

Motor parts are fabricated utilizing strategies, for example, turbine blades, casings and housings. Complex machining guarantees the aircraft propulsion framework works reliably and productively.

4.3. The construction industry:

Structures, extensions, and foundation ventures require structural steel fabrication. Beams, segments, trusses, and connectors give quality and stability fabricated from metal.

Design metalwork incorporates facades, steps, railings and enriching highlights fabricated from metal which upgrade plans. Custom fabrication permits elaborate plans.

4.4. Consumer goods manufacturing:

Metal fabrication is utilized as a part of delivering family apparatuses like refrigerators, cookers, washing machines and cooling frameworks. Parts guarantee sturdiness, usefulness and stylish allure.

Metal furniture, including tables, seats, cupboards and racks is created utilizing fabrication strategies. Custom furniture fabrication permits plan savvy and sturdy plans for private and business settings.

4.5. The Medical Device Industry:

Hardware utilized in clinical strategies requires metal fabrication. Sterilizable steel, titanium, and bioequivalent combinations guarantee exactness and unwavering quality.

Fabrication strategies manufacture implantable restorative gadgets like pacemakers, orthopedic inserts and dental restorations. Long haul execution and similarity are guaranteed.

Different enterprises depend on metal fabrication to deliver basic parts and items with exactness, unwavering quality, and flexibility. Modern applications incorporate a car, aviation, development, customer items, and restorative gadgets underlining its irreplaceable job.