- Capabilities

-

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

Electrical Discharge Machining Services

Get metal parts with delicate structures like with EMD processes.

All your designs are secure and confidential

What is electrical discharge machining?

Electrical Discharge Machining, or EDM, represents a precise non-contact machining technique that shapes workpieces through electrical spark erosion. Ideal for delicate projects, EDM exerts no cutting forces on the workpiece.

Electrical Discharge Machining Capacities

At ECOREPRAP, we offer two EDM processes tailored for cutting deep pockets and intricate features like gears and keyway holes. This non-contact method excels in crafting delicate structures.

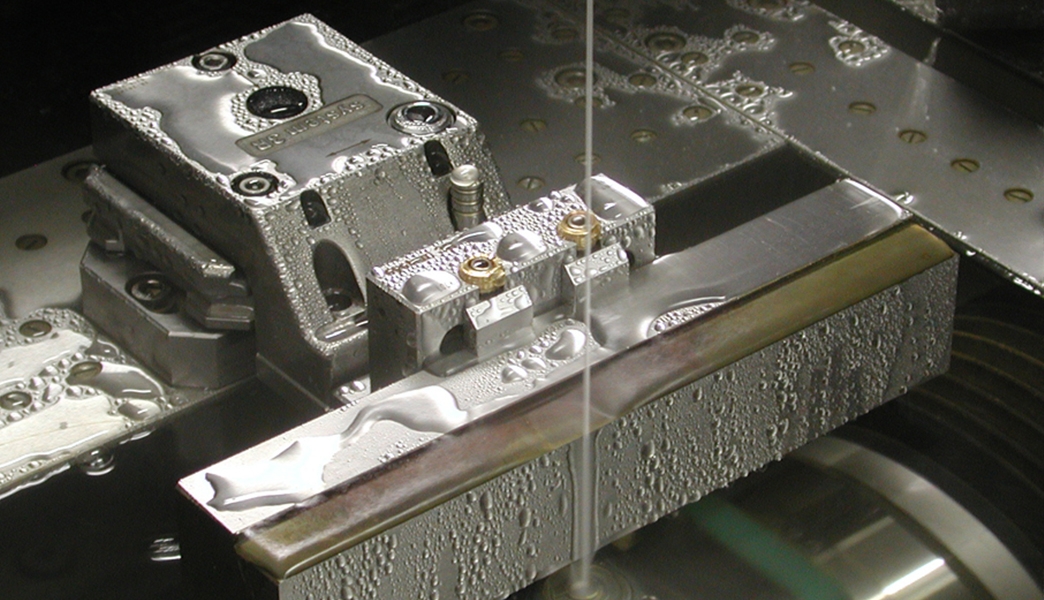

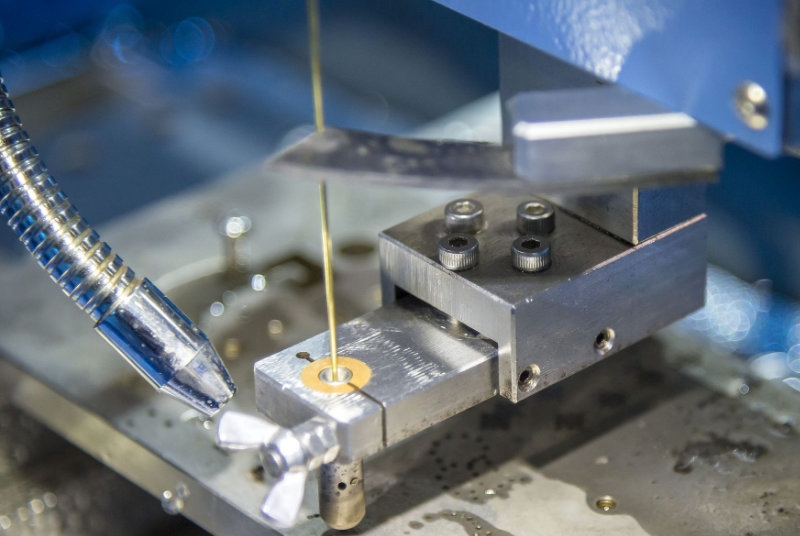

Wire EDM

Wire EDM involves submerging a metal part in dielectric fluid, with an electrically charged wire fed through it. The electrical current passing through the wire generates sparks, effectively cutting the material to achieve the desired component shape. Wire EDM proves optimal when there’s adequate clearance above and below the part feature. Our wire diameters range from 0.05 to 0.25mm, with wire options including brass, zinc-coated, and diffusion-annealed variants. Wire cutting is categorized as fast, medium, or slow wire cutting based on accuracy, surface finish, and processing requirements.

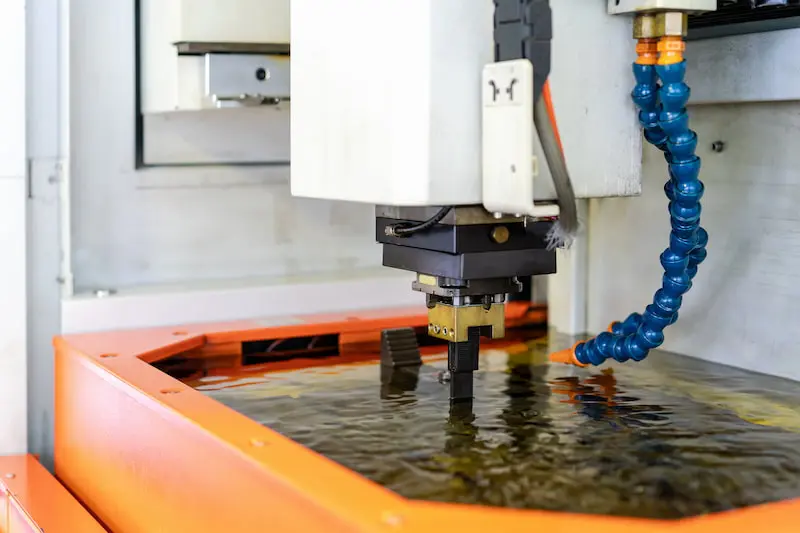

Sinker EDM

Sinker EDM begins by machining an electrode into the desired cutout shape. This electrode is then charged and plunged into the metal component submerged in dielectric fluid. The resulting electrical discharge creates sparks, shaping the internal feature as intended. While Sinker EDM is versatile for crafting bevel gears, internal gears, spiral gears, and worm gears, it’s a slower and costlier process, making it suitable for select applications. Sinker EDM shines when creating hard-to-reach angular internal features like blind keyholes, impossible to machine using other methods.

Other Machining Services

CNC Machining

Milling, turning, and post processing

- Tolerance down to ±0.001mm

- Lead time from 2 business days

Sheet Metal Fabrication

Laser cutting, bending, and post processing

- Tolerance down to ±0.1mm

- Lead time from 3 business days

3D Printing

SLA,SLS,MJF,FDM,SLM

- ±0.3% with a lower limit of ±0.3mm

- Lead time from 1 business day

Vacuum Casting

Quality parts without tooling investment.

- Durable for 20 or more copies

- Lead time from 7 business days

Electrical Discharge Machining FAQs

Both wire and sinker EDM can only be used on materials that can conduct electricity, because the electrode needs to be able to wear away the material. This limits the EDM process to metals.

Wire EDM machines can handle jobs that can be too intricate or delicate for other methods of machining, such as internal fillets, corners, or other very small and complex parts.

The EDM process consists of a metal part being submerged in dielectric fluid, where an electrically charged wire is then fed through the submerged metal component to make the precise cuts.