Thread Milling: What It Is And How Does It Work?

Updated: December 06, 2023

Table of Contents

- 1. What is Thread Milling?

- 2. Why Thread Mill CNC Is Important?

- 3.How Does a Thread Mill Work?

- 4. What Is Thread Milling Used For?

- 5. Important Parts For Threading Machining

- 6. What Are the Types of Thread Milling Cutters?

- 7. Thread Milling vs Tapping Difference

- 8. How Do I Choose a Thread Mill?

- 9. Summary

Thread milling, or hole milling, is a metalworking process that uses the beveled motion of a rotating tool in a circle to cut threads of various sizes, with the pitch being generated by the transverse motion within the circle. Thread milling has a wide range of applications in machine shops, sometimes even replacing CNC tapping.

Let’s take an in-depth look at CNC milling, the threading process, and types of threading tools, and learn more about how it differs from tapping.

1. What is Thread Milling?

Thread milling is a precise metalworking process that uses a machine tool spindle to create threads of different sizes.

The spindle is the rotating part of the CNC thread milling tool and is used to design the cutting tool for thread milling. By removing small chips from pre-drilled holes, CNC thread milling cutters can machine different types and sizes of threads.

Thread milling tools offer several advantages over conventional tapping, enabling the use of a single tool size that can be adapted to different machining tasks.

A single CNC cell can produce a variety of validated ideas, which consider the following points:

They differ in the direction of the thread winding axis. Left-hand threads are made by a clockwise spindle movement and left-hand threads are made by a clockwise spindle movement.

- Workpiece material. Traditionally, thread milling cutters are metalworking CNC units that require metal inserts to accommodate screws, even in wooden parts. If a softer or harder metal tool is used, the build uses the metal type.

- Hole Diameter. Depth of threaded engagement. Height of threaded engagement, which is an indicator of how consistently coaxial assembly threads overlap each other.

External or internal thread, a cutting tool for machining cylindrical or conical external or internal surfaces. The latter is used for machining screws, while the former is used for machining bottle caps, etc.

Thread Grade. It is simply the alphanumeric name of a thread showing its grade of machining tolerance and allowance.

Thread Tolerance. Based on the previous considerations, the accuracy that can be achieved with threads is also important.

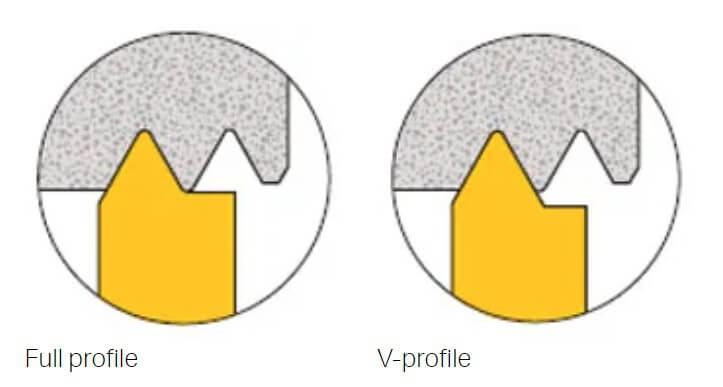

Insert type. For single-row threads, there are two types of insert profiles, full profile and V profile. They are slightly equivalent to threading methods; try keying in these profiles.

2. Thread milling cutters Why is CNC so important?

CNC thread milling has revolutionised the way threads are produced with a level of precision, efficiency and versatility unmatched by traditional methods.

Precision and Functionality

Productivity

CNC machining centers are indispensable for reducing machining speeds, increasing machining efficiency, reducing machining costs and improving product quality.

Advanced Controls

Machinists can adjust parameters such as thread milling speed and feed to meet specific requirements. This control ensures consistent thread quality and produces similar thread profiles.

Adaptability to different systems

CNC thread milling is used to machine a wide variety of materials, including hard metals and alloys. Using a thread milling machine ensures that threads meet exacting quality standards.

With intruders

threads are reliable and accurate in comparison to the increasingly popular task of thread milling.

3. How does a thread mill work?

Conventional single-point threading is achieved by cutting and forming operations. It creates a slot with a specific thread with the help of an insert (tool) with the appropriate size and thread. This thread is used for mounting screws in it. The following are some of the aspects of threading:

- This section focuses on the process of spindle rotation. uniformly into a flat surface. To achieve spindle rotation. the CNC machine unit follows a set of commands.

- The machine unit. a CNC thread milling machine is a machine with three-axis control and helical interpolation. Technically, there are special thread milling machines, but automation centers such as CNC milling and turning can also perform this operation.

- In any case, the CNC unit requests a G-coded file that will precisely define all operations. For example, given a 3-axis thread mill, an engineer could spindle write commands to move 50 mm along the X-axis, then 20 mm along the Y-axis, and then lower it 10 mm along the Z-axis. He would then write commands to start rotary motion while lowering the spindle along the Z-axis. By generalising, the CNC thread milling tool allows for precise commands.

- Modelling. Normally, G-code files are generated automatically. This is done by clicking on a computer-aided manufacturing (CAM) file with a 3D model of the workpiece and converting it to a G-coded file.

Eventually, the finished threads are threaded through the tool and the tooling. The picture shows the internal machining process of a thread.

4. What is thread milling used for?

Thread milling is a versatile precision metalworking process that can be used to machine threads on a wide range of materials.

Internal and external threads: Thread milling is versatile and can be used for both internal and external threads. For example, you can use it to machine threaded holes or external threads on rods and shafts.

High-precision threading: Used in the production of aerospace, automotive, medical devices and more.

Machining hard materials: CNC thread milling is particularly suited to machining threads in hard materials such as stainless steel and titanium, ensuring durability and strength in high-stress environments.

Large and Small Diameter Threads: Thread milling can machine a wide range of thread sizes, from very small to very large diameters. This flexibility makes it suitable for a wide range of applications, from miniature electronic components to large industrial machine parts.

Customized thread profiles: A significant advantage is its ability to produce customized thread profiles for special applications that cannot be met by standard thread forms.

5. Threading Highlights

You probably already know how threads look and work. However, the accuracy of threading will be very low due to the wear of the tool during the threading process, which leads to a decrease in the accuracy of the machining.

Therefore, a thread is a cutting tool that utilizes its sharp edges to transfer motion to execute a program with the following components:

- Root. The root is a part of the thread surface that connects adjacent conventional forms. The root extends across the entire thread to connect with the tool’s protruding thread.

- Flank. It is the portion of the threaded surface that is in contact with the root. The axis of this intersection is jacked up.

- Tooth. The tooth is the portion of the thread surface that connects to the lateral side of the thread.

- Pitch Is the square inch of the diameter of the thread. It is simply a straight line, a plane, which corresponds in one line to the axis of the thread.

It is about 150 millimeters in diameter and 180 millimeters in diameter. - A circular scale with a diameter of 15 millimeters in an oval shape. A circular scale 15 millimeters in diameter, rectangular in shape.

- Spiral. Assuming a straight thread, the angle consists of the helix of the thread and its relation to the thread axis. The angle is complementary to the guide.

6. What are the types of thread milling cutters?

Thread milling cutters or thread cutters are tools used to machine threads by milling. They may vary in shape and size depending on the use and intended design of the thread. There are two main types of thread milling cutters:

Integral carbide thread milling cutters. These tools are better suited for machining small sized holes, and they are technically more accurate and expensive than indexable tools. They offer single-pass threading, the smoothest possible cutting action, and blind machining of a wide range of material types.

Indexable insert thread milling cutters. These milling cutters are for holes over 0.625 inches in diameter. They are more cost-effective because each insert is suitable for both right- and left-handed machining and have longer tool life. These cutters also offer single cutter production, perform blind operations and clamp reliably. They also require less machine power.

Take a look at what a thread milling cutter looks like in the picture below.

7. What is the Difference Between Thread Milling and Tapping?

Thread milling and tapping can both be used to create threads. However, this is the main similarity between them. Let’s review some different factors to outline the distinct differences between these two manufacturing processes:

| Factor | CNC Thread Milling | CNC Tapping |

|---|---|---|

| Hole Size | Can operate on almost any size hole | Typically used for small pre-drilled holes |

| Thread Quality | Thread mill size should be smaller than the hole to allow metal chips to be discharged without damaging the internal surface | Tap size should match the hole size, so metal chips might scratch the internal surface during extraction |

| Required Cutting Force | Generally requires lower cutting force, especially when using indexable insert tools | Requires higher cutting force |

| Need for Tool Change | One tool can accommodate various hole sizes when using indexable insert tools | One tool fits only one hole size |

| Fit Control | Allows fine-tuning of thread size and position | Once tapped, thread size and position cannot be adjusted |

| Labor Involvement | Can only be done automatically | Can be done automatically or manually |

| Surface Finish | Overall surface quality is excellent. Multi-pass thread milling can achieve outstanding surface finish | Surface quality is generally average and cannot be improved without additional finishing |

8. How do I select a thread milling cutter?

There are a number of aspects to consider when choosing a thread cutter to meet your needs.

Don’t go for the most affordable option. Experience has shown that cutting tools are worth every penny spent, as cheap cutting tools can break down quickly.

Blade type. As a rule of thumb, fully toothed inserts perform better overall and produce higher quality shapes with maximum precision. Also, V-shaped inserts don’t need to be purchased from too much stock, as multiple pitches may fit the same thread.

Cutting Diameter. You are free to use a thread milling cutter that is smaller than the hole. So stick with a common diameter rather than buying a different cutter for each hole size.

Evaluate the number of quick passes. It is not necessary to finish threading in one pass. In complex applications, it’s best to modify the number of passes with different sized cutters. Multiple radial passes will help you achieve finer internal surface quality. It will also improve thread consistency from batch to batch.

External or internal threads. Note the characteristics of the threading operation to be performed. An obvious example would be the need for external or male threads or internal or female threads, as mentioned earlier. Take a look at what both look like in the picture below.

9. Summary

Threading is essentially one of the simplest manufacturing operations, and is accomplished on a CNC milling or turning centre or lathe with the help of a thread milling cutter and a G-code file that specifies the instructions.

Thread milling cutters fall into two main categories, the indexable insert type and the solid carbide type. They vary in price and are suitable for different design purposes. When selecting a thread milling cutter, special attention should be paid to its characteristics and type so that the required tool will function as intended.