- Capabilities

-

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

Difference Between Feed Rate and Cutting Speed in CNC Machining

Updated: December 04, 2023

Introduction

When in CNC manufacturing, the components are shaped by cutting material of their surfaces. The approach puts some load on the cutting tools, so setting proper machining parameters for them is crucial. It impacts the overall quality, tool life, yield, and more.

Feed rate and cutting speeds are the parameters you should consider adjusting in the first place. In this post, Let’s learn more about cutting and spindle speed and feed, review complementary factors, and find out how to calculate settings.

1. What is Feed Rate In CNC Machining?

Feed rate is the units of distance the tool travels during one spindle revolution. Alternatively, it’s the distance a cutter travels during a revolution of a workpiece if you take the turning machine as an example.

The velocity at which the cutter is advanced against a workpiece is measured in inches per revolution (inch/rev) or millimeters per revolution (mm/rev). Some may prefer calculating in inches per minute (ipm) and even millimeters (mpm).

In calculating the feed rate, machinists may consider the number of flutes a cutter has and ground calculations based on feed per tooth. Flutes are sharp edges that remove the material of the workpiece.

Operators or programmists adjust speed rate together with feed rate parameters, as they are closely related. The latter is essential for the final aesthetic look in the first place.

2. Factors to Consider When Setting a Feed Rate for CNC Machine

Here are the important aspects to pay attention to while adjusting feed rate for new machining operations:

- Cut width. Any cut width that is less than half the diameter of the tool results in chip thinning. It’s a manufacturing defect where chip load, or the amount of material cut in one revolution, is reduced. It instantly results in a longer machining time. Increasing the feed rate helps to alleviate the effects of chip thinning.

- The tool type. Cutters may have optimal feed rates they can work with or feed rate limitations. It depends on the type of tool its material, its coating, and more.

- Surface finish. Surface roughness increases with the increase in feed rate. When an engineer needs the smoothest finish, they choose low feeds but high speeds.

- Machine spindle power. The power available is also important as some machines and tooling may not be able to apply enough pressure to push the cutter through the material.

- Strength of the workpiece. It’s simple — the more durable the material is, the higher feed rates it can withstand without having the workpiece surface chipped, cracked, etc.

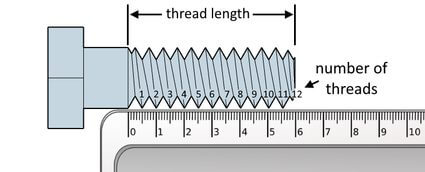

- Threads per inch (TPI). It’s the number of threads per inch along the length of fasteners/ threading tools. The parameter is crucial when you are making a hole to accommodate a screw.

Take a look at what TPI looks like in the image below.

3. What is Cutting Speed in CNC Machining?

Cutting speed is the velocity between the surface and a cutting tool. Surface speed may also be defined as how fast the workpiece moves past the cutting edge of tooling. It depends on a tool’s diameter and revolutions per minute (RPM).

Machinists measure cutting speed in meters per minute (m/min), millimeters per minute (mm/min), or feet per minute (ft/min).

Cutting speed is an essential setting because it impacts cutting temperature, electricity consumption, finish accuracy, tool life, and others.

4. Factors to Be Considered For Cutting Speed in CNC Machining

It’s easy to predict the optimal cutting speeds for machining processes. However, before proceeding any further with computing, you should consider these factors, especially when incorporating techniques such as laser cutting:

- Cutting tool type. There are multiple different cutters, each of which can withstand different amounts of stress. Even if two cutters are made of the same material, they may be shorter, longer, or have other shapes and forms, which contribute to their capacity to support high speeds for a prolonged time.

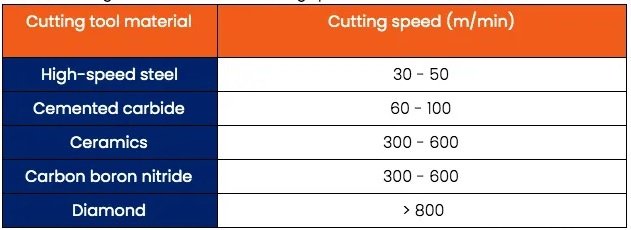

- Cutting tool material. Cutters may be made out of various materials. Concerning the pros and cons of materials, they can withstand different speeds. If a cutting material is of lower strength, high speeds will make it wear out quickly.

- Tool life. This variable also should be paid some attention to. If you use slightly worn tools, don’t try to push them to their limits, or they may quickly fail. On the contrary, if you want a tool to last for a prolonged time, high speeds may be favorable to use.

- Strength of the workpiece. Once again, durable workpiece materials better withstand high physical and temperature stresses. This means that higher speeds are feasible for such workpieces.

- Workpiece hardness. Besides the durability or strength, there is such an aspect and the workpiece’s hardness. The higher this parameter is, the harder is to cut through the material. It makes it necessary to use lower cutting speeds to reduce rapid tool wear.

You may see some optimal cutting speeds based on the tool material.

5. What is the Difference Between Feed Rate and Cutting Speed?

Let’s summarize the info for speeds and feeds and compare them based on several criteria:

- Cutting temperature and tool life. Higher cutting temperatures compromise parameters such as tool life and surface finish quality. At the same time, the feed rate has a slightly lower extent of its effect on the cutting temperature.

- Surface roughness and scallop marks. Higher feed rates cause scallop marks or scratches on the surface of a workpiece. It’s because of the surface roughness that may not match the chosen feed rate. Spindle speeds do not show a direct influence on scallop marks’ appearance.

- Generatrix and diretrix. The first is a point that generates a new shape when moved along a part. The path through which the generatrix moves is called the directrix. These two parameters are the geometric rationale of machining. Speeds provide the generatrix, while feeds provide the directrix.

- Units of measurement. Speeds are measured in meters or feet per minute. Feeds are measured in meters, inches, or millimeters per revolution.

- Power consumption. Cutting speeds are what affect force and power consumption in the first place. Feed rates contribute to a lower extent.

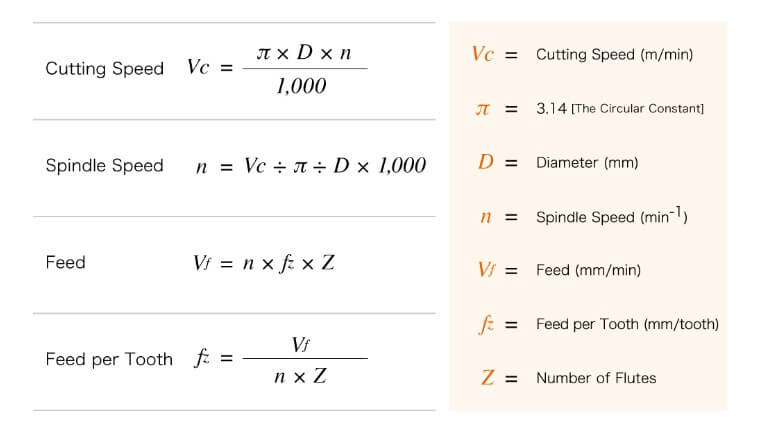

You may see how some machine settings find their application in machining in the image below.

6. How to Determine Cutting Speed and Feed Rate?

Optimum cutting speed and feed are determined through calculations for every new cutting process. Take a look at the image below for some basic formulas.

As you may see, some parameters, such as the number of flutes or tool diameter, much depend on the tooling in use. Other parameters, such as feed per tooth or cutting speed, you should define yourself. Feature the factors mentioned above for this purpose.

Start with finding the optimal feed per tooth and cutting speed, and proceed with other formulas further. Remember, for most machining conditions, there are no universal solutions. It may take more than one attempt to find optimal machining parameters.

7. Summary

The value in finding the difference between feed rate and cutting speed is rather theoretical. Both settings or parameters are due to be adjusted for every machining process. Speed affects how fast the cutter rotates, while feeds affect how much material is cut off with each revolution.

The essential thing to know is how to calculate these parameters. Start by examining the parameters of your tooling, and then pay close attention to machining aspects such as the hardness of the material, the strength of the workpiece, etc. After several attempts, you’ll manage to find suitable speed and feed rates that would wear your cutters optionally.

Let's get your projects started, together!

Get custom parts machined in high quality, delivery on time.