- Capabilities

-

CNC Machining

Tight tolerance and 20+ finishes 3, 4 , 5 axis, as fast as 2 days -

Sheet Metal Fabrication

High-precision, on-demand sheet metal cutting and bending. -

3D Printing

SLA, SLS,MJF,SLM, FDM 3d printing with post treatment. -

Vacuum Casting

Production quality parts without the tooling investment.

-

- Solutions

Rapid Prototyping

Fastest lead time of high-quality prototypes at minimal cost.

Low Volume Production

From one-off prototyping to low-volume production.

Mechanical Assembly

Custom assembly for project-specific needs.

Custom Package

Ready to help you prompt your brand.

- Sources

Materials

Select from 100 more types of metals and plastics.

Finishes

Select from 20 more types of surface fishes.

Industries

Providing precision machining and manufacturing solutions.

Cases

How we assist our clients in bringing their projects to fruition.

- Company

Quality Assurance

Consistent quality, every time.

About Us

Your go-to manufacturer for custom parts.

Newsroom

Learn updated news about ECOREPRAP.

Source Custom New Energy Parts

- Quote complex parts with detailed DFM feedback

- Huge range of technologies and materials

- Fast and reliable manufacturing options

All your designs are secure and confidential

New Energy Parts Manufactured

- End-use components

- Repairs or replacement

- Rapid tooling

- Custom tooling

- Jigs

- Brackets

- Custom fixturing

- Fit check gauges

- Composite tooling

- Chassis

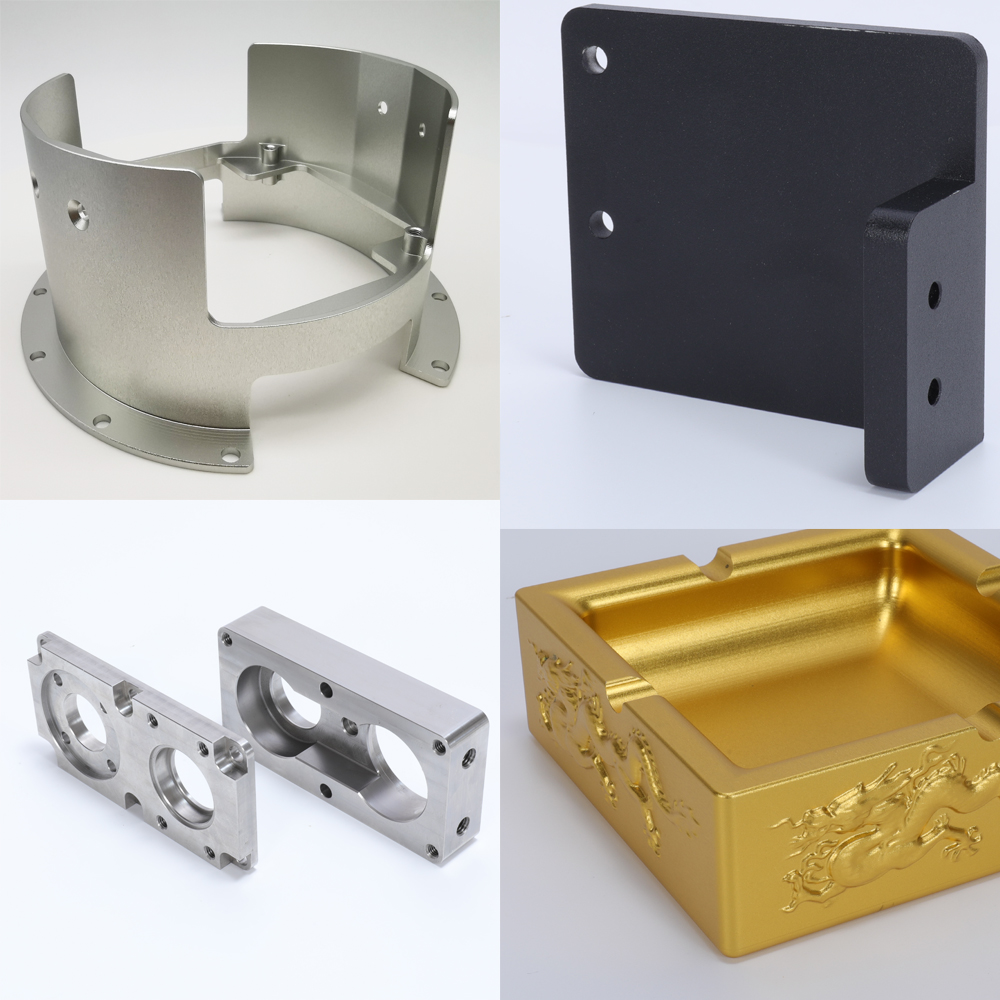

New Energy Manufacturing Capabilities

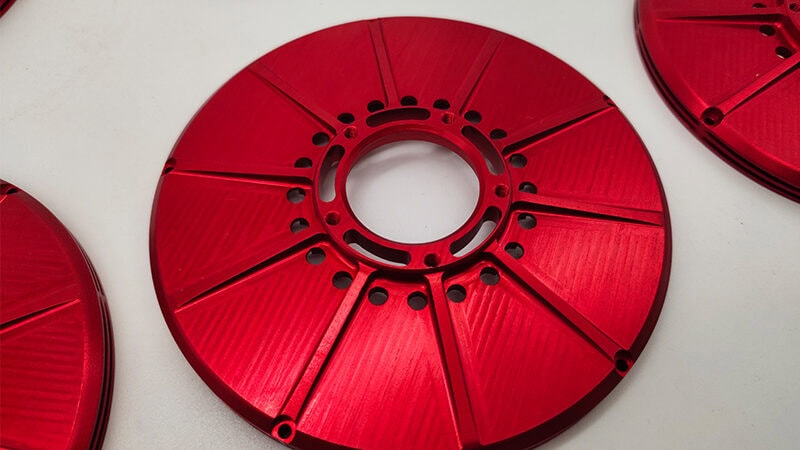

CNC Machining

Milling, turning, and post processings

- Tolerance down to ±0.001mm

- Lead time from 2 business days

Sheet Metal Fabrication

Laser cutting, bending, post processings

- Tolerance down to ±0.1mm

- Lead time from 3 business days

3D Printing

SLA,SLS,MJF,SLM,FDM

- ±0.3% with a lower limit of ±0.3mm

- Lead time from 1 business day

Vacuum Casting

Production quality parts withouthe tooling investment.

- Durable for 20 or more copies

- Lead time from 7 business days

New Energy Parts Materials & Surface Finishes

We give you access to a huge range of materials and surface finishes for every application.

New energy materials

Select from a broad range of industrial-grade materials

Steel & stainless steel: 303, 316/316L, 15-5, Tool Steels, 4140, 1.7225Aluminum: 6061-T6, 6082, 7075-T6, 5083-H111, 2017

Brass & Copper Alloys: C360, Copper C110, Copper C101

Thermoplastics: Polyoxymethylene (POM), PEEK, PET

Commodity polymers: Polyethylene (PE), Polypropylene(PP), PVC

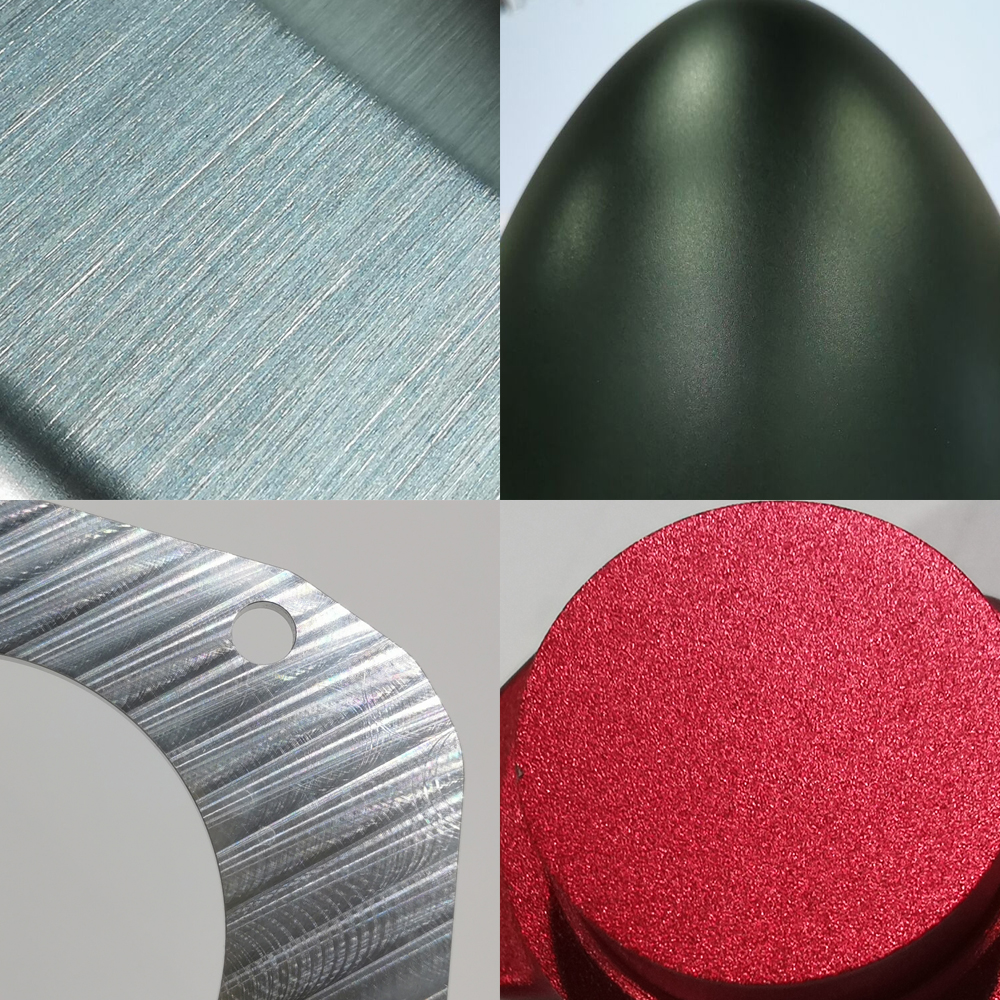

New energy surface finishes

Improve durability and performance with a selection of finishes

AnodizingElectroless nickel plating

Black oxide

Chromate conversion coating

Powder coating

Passivization

Insert installation

Heat treatment

How ECOREPRAP Helps New Energy Companies Innovate

Consistent Quality Every Time

We use high-quality input materials and maintain a high level of process stability to ensure reproducibility. We strive for continuous improvement to improve our manufacturing of goods, processes, and delivery capability.

Professional Engineering Support

Work with our engineering experts that offer technical design guidance and inform you on manufacturability and cost-saving solutions. Free and accurate quotation with DFM review in 12 hours and lead time as fast as 3 days.

Strong Manufacturing Capacity

To meet your rapid prototyping needs, we provide and support extensive manufacturing capabilities, including 3D printing, CNC machining, sheet metal fabrication and vacuum casting.

Worldwide Shipping Solution

We have a state-of-the-art in-house production supply chain and staff strength that helps us meet and exceed your expectations on delivery time and quantity. We ensure that all our deliveries are within schedule.

FAQs

We do thorough checks of every manufacturing partner (MP) during the initial onboarding process and perform audits on processes and certifications every two years. To source parts from certified MPs, you can indicate these requirements on the platform or contact info@ecoreprap.com. We’ll match your designs with the right supplier.

We take on all the risks for you. If your parts aren’t up to spec, you can file a dispute claim and we’ll remake your components or refund your order. For more detail on how we handle disputes, you can contact our Customer Success Team. At the same time, we complete non-conformity reports for parts that don’t meet all requirements, with follow-up with manufacturers including root cause analysis and rapid corrective actions.

If you want to get parts in specialized materials that aren’t listed on our site or platform, you can send a request to your account manager or contact info@ecoreprap.com.