SLA 3D Printing: Is UV Resin Toxic?

Updated: May 05, 2024

You probably have heard about stereolithography (SLA) as additive manufacturing using liquid filaments (resin). You may also know some health concerns associated with the potential toxicity of UV resin used in the process.

Can I be frank with you? Safety implications are crucial while performing machining operations.

We will explain how 3D printing resin is toxic and provide some tips for its use.

1. What is 3D Printer Resin Made of?

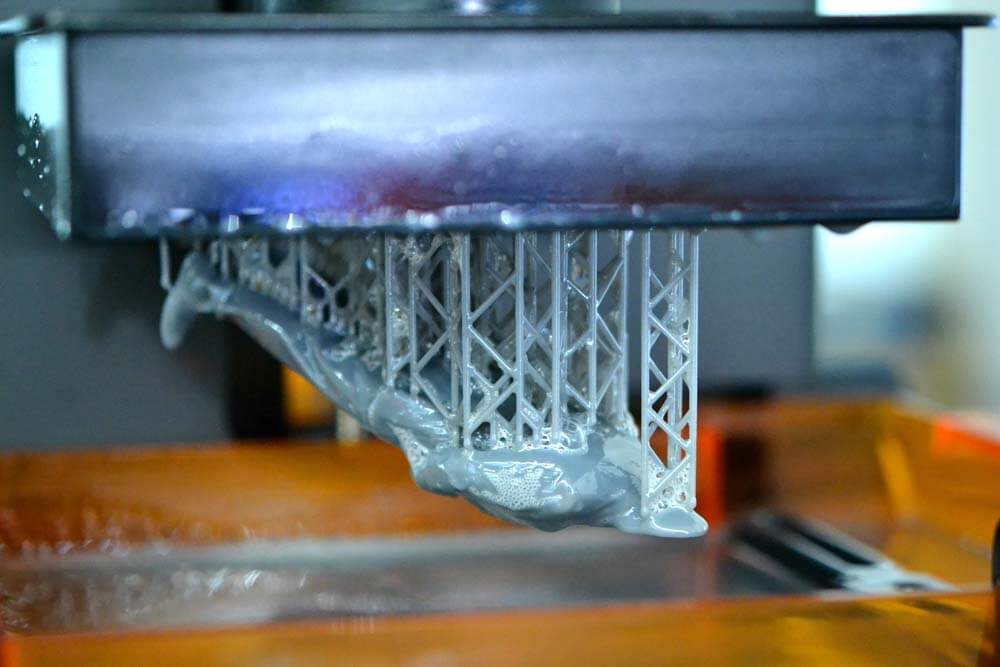

To further detail reasons for the toxicity of UV resin, an initial insight into components of the material and some of its properties is due. The substance typically called “resin” is actually the light-reactive thermoset material.

This temporary liquid solution consists of carbon-based molecules monomers and unions of such monomers called oligomers. Those dissociated carbon molecules and short carbon chains do not form a particular structure that could have given a resin some sort of solid “frame.” That is why the material is in a liquid state until it is exposed to ultraviolet (UV).

Let’s dig a little deeper. After resin receives some light energy, the reaction called “photopolymerization” is triggered. It destructs ends of those monomers and oligomers making them stick to each other, thus expanding carbon chains and forming polymers.

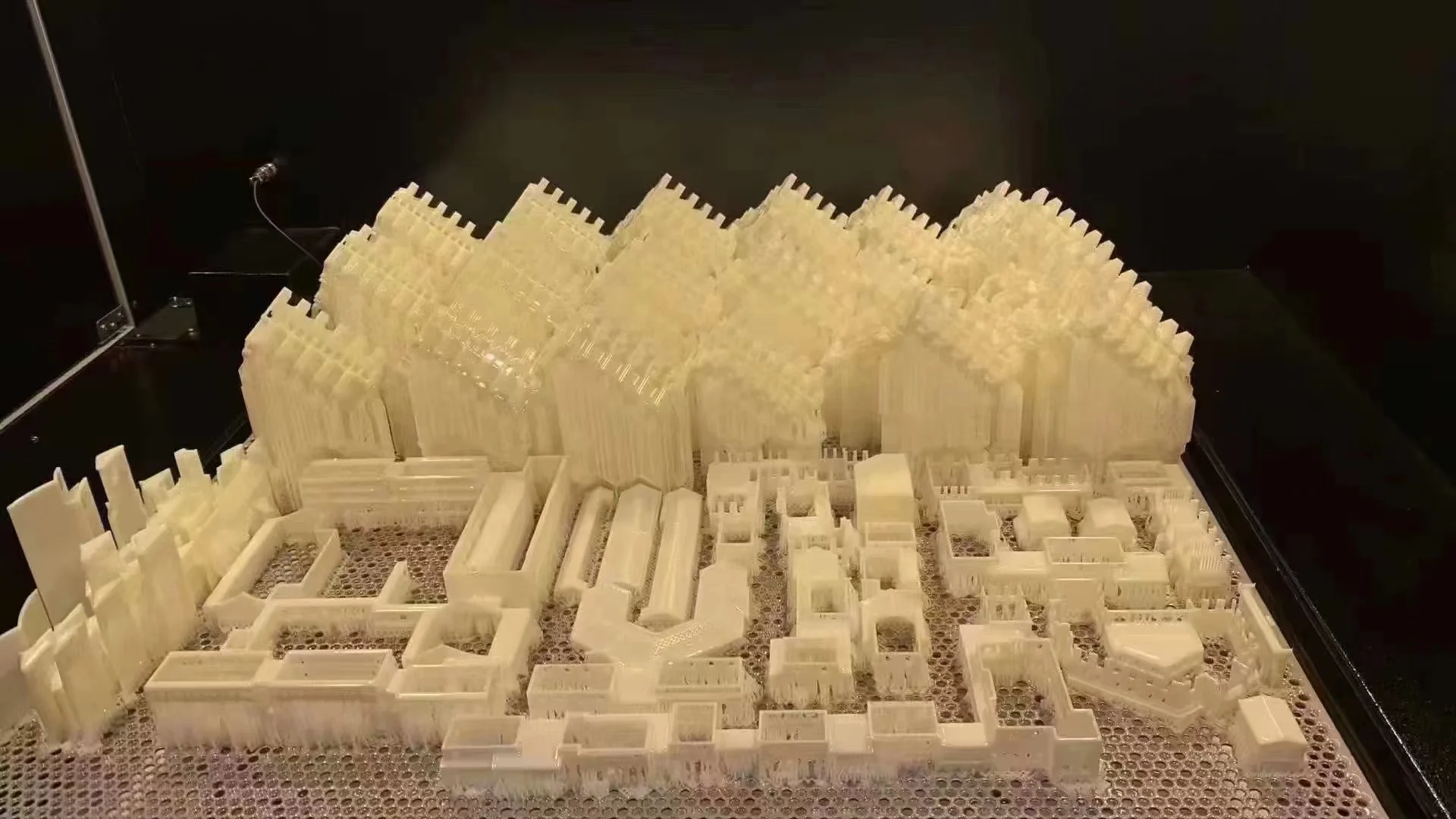

The newly obtained macrostructures become big enough to form a solid frame, thus transforming formerly liquid resin into something similar to hard plastics. The described process is the simplified description of SLA/resin printing, as well as the containments of both liquid and solid states of aggregate of UV resin.

2. Why is UV Resin So Toxic?

Safety implications associated with resin-based manufacturing are listed below, as well as the toxic effects of the material.

Irritation to the skin and respiratory system.

To begin with, we highly recommend you prevent exposure of unprotected skin to 3D printing resin in the liquid form. While containing mostly carbon-based oligomers and monomers this substance can easily get under the dense inner layer of skin (derma).

The molecules discussed above are also the components of gas oil and diesel fuel and may eventually cause contact dermatitis known as surface rush, potentially allergic one.

The other long-term consequence of working with UV resin is irritation in the lungs. It is caused by liquid resin giving off fumes, which can be easily breathed in unless respiratory protection is worn or an area, where additive manufacturing is performed, is well-ventilated.

Permanent harm when exposed to eyes or ingested.

As well as not many people would rinse their eyes with petroleum products, it is equally not recommended to let liquid resin be applied to the eyes. Overwise it may result in transient corneal injury, and even some forms of burns. It is also difficult to wash away.

Ingestion of UV resin leads to its absorption from the both respiratory and gastrointestinal tracts. It may result in severe intoxication. For some individuals, it may be fatal. Typical signs of such intoxication are vomiting, vertigo, loss of consciousness, convulsions, and hemorrhaging of the lungs.

Toxic to the environment.

Not only workers involved in manufacturing with the use of 3D printer resin are vulnerable to its toxicity. Nanoparticles of the materials, which are unavoidable byproducts of SLA printing, can easily reach groundwater or any other sources deriving into seas and oceans. This way resin causes a deteriorative influence on aquatic ecosystems.

Molecules of printer resin can be attached to the central nervous system of aquatic animals, thus damaging neurologic processes. Frequently, it leads to killing large masses of fish.

3. Tips for Using UV Resin

Let me guess – you are a bit concerned and unsure about using UV resin after reading the points discussed above? But here are some tips for safe SLA 3D printing.

Warning!

Suppliers of 3D printer resin are legally obligated to provide you with a Material Safety Data Sheet (MSDS) containing vital health information and safety precaution for a particular resin product.

Not expose a 3D printed resin-based object to UV light for too long

It is a frequent mistake that to let an object “fully harden” workers keep it under light for 10 minutes or even above. However, there is a substantial risk that resin in the solid state would begin decay, thus letting polymers lose their structure. It leads to the material partly returning back in the liquid state, consequences of which are detailed above.

As a rule of thumb, exposure with a duration of about 6 minutes is typically enough for a printed object to be solid completely. It is also correct even for large printed pieces, as long as they are cured by UV light entirely, and no parts left unexposed.

Prepare protective equipment and not neglect using it.

Thus, there are sets of equipment necessary to work with UV resin safely. These include chemical-resistant gloves for hands, safety goggles/ laboratory glasses for eye protection, and clothing that fully covers arms, legs, and torso. Ideally, a disposable overall or a protective gown and a respirator mask (such as FFP2/FFP3) should be worn.

Those protective equipment units are to be used during assembly and disassembly of the printer during post-processing of printed parts as well, for reasons explained above.

Ensure sufficient working conditions.

Basically, employees need a well-ventilated room for working with UV resin. Under no circumstances should they inhale synthetic resin vapors. An effective ventilation system should stop condensation, regulate air flows, maintain a constant temperature, and ideally control pollutants in the air.

After printing.

Safety tips offered include measures for risk reduction after SLA printing is over. Thus, the excess resin in the tank of the printer should be carefully poured into a container through a sieve back.

Then, it is necessary to eliminate liquid resin on the printing platform left. We recommend doing it with a 3D printing fan applied on the printing plate, diagonally positioned over the tank. The remaining adhesions can be wiped with paper tissues.

Put printed parts in a container with isopropanol and swivel the container until the excess resin has dissolved from the surface. As an alternative, you may consider rinsing the printing plate, with a printed object on it, with isopropanol. Make sure you have a container big enough for such a purpose.

Waste disposal.

Depending on your country’s legislation, resin to be disposed of should be previously cured and approached as a normal trash. Overwise, you may consider filtering out the resin leftover from isopropanol via the recycling center.

4. How to Store UV Curable Resins

Concerning all the points detailed above, some appropriate conditions should be ensured to safely store curable resins.

Resin-proof containers.

The general requirement is that UV-curable resins are stored in tightly sealed containers explicitly intended for this purpose. It is vital not to fill those tanks to the very top. It may lead to resin gelling.

At the end of the gel phase, UV resin will become stringy when trying to stir it and eventually harden fully. It makes using such resin impossible because it is already solid and cannot be shaped or melted to the initial state.

Warehouse area conditions

The other important factor is room temperature. To make sure that resin would not deteriorate in any way, the temperature of the warehouse where containers are stored should comply with the resin supplier’s requirements.

It is also vital that areas where containers with UV resin are placed are dark and dry. Not adhering to such requirements also leads to resin gelling.

Not to store resin alongside products for consumption

The frequent mistake is storing resins that require being kept at lower temperatures in domestic refrigerators, where products for humans or animals are present. Concerning the toxic properties of the UV resin, it should be stored in specifically allocated places where potentially dangerous particles cannot diffuse into products for digestion.

5. Final Word

In a nutshell, without professional treatment, UV resins for SLA printing can be highly dangerous for both humans and the environment.

Safety precautions should be taken to prevent carbon molecules from manifesting their toxic properties. Protective measures and specific storage conditions have a great chance of preventing workers from being exposed to resin particles.

SLA printing is not that hazardous if approached correctly.