ECOREPRAP Standards

ONE-CNC Machining Tolerance Standards

General Tolerance

Tighter Tolerances

ECOREPRAP CNC Machining General/Standard Tolerance

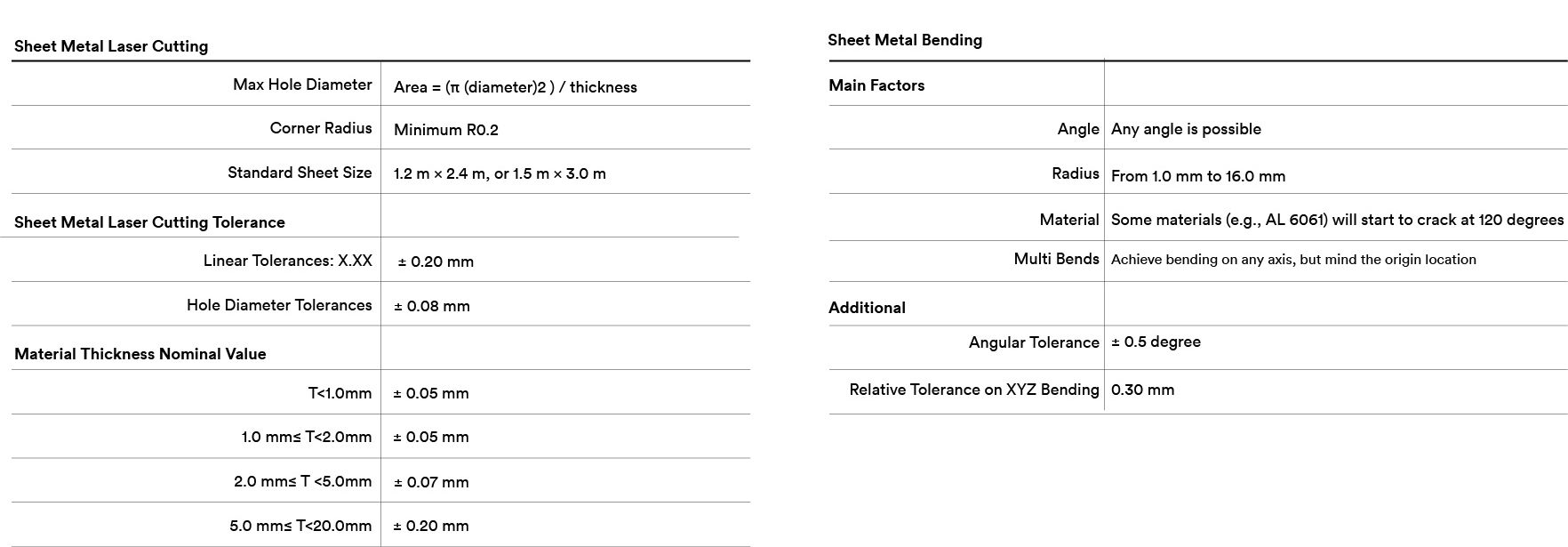

TWO-Sheet Metal Fabrication Tolerances Standards

ECOREPRAP provides two categories of tolerances: “GENERAL TOLERANCE” and “TIGHTER TOLERANCES”.

General Tolerance

General tolerance is the tolerance across the part if nothing is indicated on a technical drawing.

Tighter Tolerances

If tolerances tighter is requested,it also needs to be specified in a technical drawing in order to indicate exactly which features are concerned.

ECOREPRAP Sheet Metal Fabrication General/Standard Tolerance

THREE-CNC Machinging and Sheet Metal Fabrication Parts Edge Breaking and Deburring Standards

Standard:

1. Deburring comes as a standard with all finishes.

2. Standard is deburring plus break sharp edges (chamfer).

3. No secondary burrs allowed.

4. Chamfer size rang is 0.25mm ±0.15mm.

5. Internal threads, bores and blind holes will also be deburred with the aid of deburring brushes when need be.

6. Chamfers will be done during the machining steps as much as possible, to ensure a consistent look.When not possible, these can be done by hand with a regular hand deburring tool.

Non-standard:

FOUR-CNC Machinging Cosmetic Standards

Cosmetic Definition

Finishes are differentiated into two categories, cosmetic and non-cosmetic. Cosmetic is the best option when visual consistency across batches is required and parts cannot have cosmetic defects on their “primary” side. Non-cosmetic is the less expensive option. Parts can present slight visual differences and cosmetic surface imperfections.

When you select a cosmetic finish, we commit to producing high-end, customer facing products. We guarantee that you will receive “beautiful-looking” parts according to our cosmetic standards described below.

FIVE-Threads Standards

Threads Types

UNC and UNF

- Defined by the Unified Thread Standard (UTS)

- UTS standard: ASME/ANSI B1.1 – 2019

Thread tolerances

Metric Threads Tolerances

UN Threads Tolerances

Important Note:

If your parts need to pass through GO-NO-GO gauge, please indicate it when placing the order or on the 2D drawing.

SIX-Cosmetic Standards-Visually Consistent For The Same Batch

1. Brush marks will be in the same direction.

2. Same grit will be used across parts for sanding or brushing.

3. Color will be consistent to the same hue when parts are placed next to each other.

4. Gloss units will be consistent across the batch.

5. Only minor defects are allowed on the hidden B side.

6. Surface quality on our side upon receiving will be visually inspected at a distance about 50cm in a pproximately 45 degrees in all directions. Lighting conditions are 500-1000 Lux.

| Defects | Primary side (A side) | Secondary side (B side) |

| Scratches, dents, stains, blemishes | None | None |

| Hanging marks | None | Minor hanging marks |

| Minor defects | None | Up to two minor defects |

SEVEN-Inspection Standards

A defect is considered as a discrepancy to ECOREPRAP technical requirements and/or customer specifications.

Our QC will carry visual and dimensional inspections prior to order shipping. We use standard defect books and inspection criteria that help us to get a consistent level of control, wherever and whenever the order is produced. For an order with multiple units of the same line item, our partners and inspection teams use ISO2859 – General Level 2 sampling.

For example, a batch of 20 units will be inspected on a sample of 5 units.

Defects are described with pictures, as well as level of defect (which are linked to AQL levels for inspection purposes).

The defects are described with 5 properties:

1. Category: Surface finishes, Tolerances & dimensions, Threads, Materials, Parts finishing & Cleaning, Packaging.

2. Name: description of the defect

3. Level: criticality of the defect

4. Bad photo: example of the defect

5. Good photo: example of an acceptable part

Categorisation of defects levels

1. Minor defect

Minor defects usually slightly affect parts appearance but usually do not affect parts usability.

2. Major defect

Major defects are more serious defects that can affect parts usability.

3. Critical defect

Critical defects are defects that affect part usability, and that could lead to harmful or hazardous situations if the part is used as it is.

EIGHT-Non Standard Features Requirements Standards

Non Standard Features Requirements – Sharp Corners

Internal sharp corners necessitate EDM (Electrical Discharge Machining) operations, resulting in a substantial increase in machining expenses. Consequently, it is advisable to minimize the presence of such sharp corners whenever feasible. In the majority of cases, if there is a request for sharp corners, the supplier will propose alterations to enhance the part’s machinability.

If the sharp corners are not absolutely indispensable, we would suggest two solutions.

Solution 1: Increasing the radii

A radius of at least 1/4 of the pocket depth can be suggested

For example, this pocket is 10mm deep, at least 2.5mm radius will be suggested.

Solution 2: Use corner compensation fillet

“Dog bones” fillet can be suggested

Corner compensation fillet is a technique used to add small rounded corners or fillets to the inside corners of a design. These fillets are applied to compensate for the diameter of the cutting tool used in the machining process. The purpose of adding these fillets is to ensure that the machined part accurately fits the intended dimensions.

Corner compensation fillet is often called as “dog bones”, because it looks like a dog bone shape.

1. CNC engraving, laser engraving and silk screening are provided on demand.

2. Vector file (AI, CorelDRAW, Autocad, DXF) PDF with exact positioning of marking shall be provided.

3. By laser engraving, the depth is about 0.08mm to 0.5mm, usually grey color.

For any other no standard features requirement, please contact us info@ecoreprap.com.

NINE-Quality Documentation Standards

| Definition | Additional Cost | Technology | Minimum Order Value | Required | |

| Certificate of Conformance | A Certificate of Conformance certifies that a particular order has been delivered with the required order specifications. Certificates of Conformance are available for CNC and SM only. | Yes | CNC Sheet metal fabrication | None | Through your project manager |

| RoHS Certificates of Compliance | RoHS stands for Risk of Hazardous Substances. It is a legal requirement in EU. It is typically required to ensure that parts have been manufactured responsibly. | Yes | CNC Sheet metal fabrication | None | Through your project manager |

| REACH Certificate | A REACH Certificate declares that the materials used to manufacture the products, including packaging, do not contain more than 0.1% of hazardous substances as per the ones listed in the European REACH regulation. It is similar to RoHS, but does not require additional testing per order to certify it. | Yes | CNC Sheet metal fabrication | None | Through your project manager |

| Material Certificates | Material Certificates are typically requested by customers to ensure the material provided meets their standards. Material Certificates are available for all materials. For metals, a material test report is encouraged instead. | NO | CNC Sheet metal fabrication | None | Through your project manager |

| Material Test Report | A Material Test Report certifies that the chemical analysis and mechanical properties are in conformance with the specified material specification. It’s also known as a mill-test report. Material testing is carried out by a third party quality lab. Material test reports are only available for metals. Chemistry testing, tensile test and hardness test are on a sample from the production batch. | NO | CNC | None | Through your project manager |

| Dimensional Inspection Report (CMM) | A Dimensional Inspection Report assesses key measurements in a small batch or full order against acceptable tolerances. Dimensional Inspection Reports can be done manually or automated with a CMM machine. In cases where CMM is impractical, manual tools are used, and the specific tool is documented in the report. | Yes | CNC Sheet metal fabrication | Depends on critical dimensions, batch size and number of different parts. $100 minimum, free for orders above $10,000USD. | 1. Critical dimensions specified on technical drawings. 2. Batch size, typically following industry standards. 3. Parts to undergo inspection. |

| First Article Inspection (FAI) | “First Article Inspection” (FAI) is a service to ensure that parts meet specifications before mass production begins. It involves thoroughly measuring and documenting all features of a part or assembly. Typically, we conducts the FAI, and the customer reviews or approves the report to ensure compliance with specifications, such as those outlined in the technical drawings. The inspected article may not necessarily be the very first produced but a representative sample from the initial production lot. FAI documentation includes: 1. Material compliance certificates, which vary for metals and plastics: · Metals: Material Test Report · Plastics: Material Certificates 2. A comprehensive Dimensional Report 3. A Production Flowchart 4. A Production Control Plan 5. A Parts Acceptance Letter Approval Procedure: Upon sample part delivery, the customer has 1 week for approval. Approval involves signing the parts acceptance letter. 1. If Approved: Mass Production proceeds, and the entire order is fulfilled as usual. 2. If Disputed for Quality Reasons: A standard dispute process is followed, and the customer can choose to cancel the order or request a remake. 3. If Declined for Design Reasons: The customer can cancel the entire order and will be responsible for the cost of the sample sets. | Yes | CNC | None | 1. Critical dimensions specified on technical drawings. 2. Batch size, typically following industry standards. 3. Parts to undergo inspection. |