Metal Part Sandblasting Cost: What to Expect in Pricing?

Updated: December 02, 2023

Sandblasting is commonly used in domestic and industrial applications to clean surfaces and remove paint or other coatings. It is also used to remove scratching and denting or removing excess material from a workpiece.

Besides the size of surface, there are other factors that add to the cost of sandblasting such as the intensity of the blasting needed, as well as other supporting processes that may need to be done on the workpiece. In this article, we will go over the factors affecting the sand blasting cost for a metal part.

One needs to know the best blasting method/abrasive material to use in order to produce a result that is both cost effective and produces good quality results. You can expect to pay between $40 to $70 an hour for sandblasting. Some companies charge per square foot, you can expect to pay from $1-$8 for light to medium duty jobs.

1. Factors that affect the cost of sandblasting

Choosing the type of blasting media is one of the greatest contributors to process cost. It must be noted here that one cannot simply choose the least expensive blasting media in order to reduce the sand blasting cost. The choice of media is dependent upon the the type of material to be cleaned.

For instance, although steel shot is a relatively inexpensive blasting media because it can be used many times over, it cannot be used with Aluminum metals because it impregnates Aluminum which will later cause rusting.

The blasting process can be charged per square foot or per hourly rate as some service providers may prefer. Sandblasting costs per square foot range from $1 – $5 and the premium services can cost as much as $16 per square foot.

The table below shows the average costs for the different types of sandblasting. The prices are an indication for light duty applications.

| Blasting Media | Cost Range |

| Hydro-blasting | $1 – $2.5 |

| Wet sandblasting | $1.30 – $3.5 |

| Dry sandblasting | $2 – $4.5 |

| Glass blasting | $2.5 – $5 |

| Dry-ice blasting | $3.50-$7 |

Hydro-blasting is one of the least expensive blasting methods because it uses no blasting media. The workpiece is cleaned/prepared only by the pressurized jet of clean water that strikes the surface.

Because no abrasives are used, the process is gentler to the workpiece surface as well as to the environment. The process is well suited for delicate materials or light cleaning applications.

The downside is that the process takes longer and sometimes cannot be used for workpieces that have many layers of paint or other coating to clean.

Wet sandblasting is one of the more affordable options. The process uses sand and water for cleaning. It is much faster than hydro-blasting and can also do more heavy-duty work compared to hydro-blasting.

While it is a dustless sandblasting process, the downside of wet blasting when used to clean metals is that rust tends to form on the surface quicker. A rust inhibitor must then be applied to the workpiece to increase its resistance to corrosion.

Dry sandblasting is usually a quick process, but the major drawback is that it produces a lot of dust.

Reference Post: Bead Blasting Finish: The Complete Guide in 2022

2. Labor cost of Sandblasting

Although a machine does the actual sandblasting, there is a considerable amount of human input in the process. Labor charges stem from processes like project management and material handling. If the workpiece is large or if it needs prepping before sandblasting, a human worker must plan the best course of action to execute the task based on knowledge and experience.

For items that may have delicate detail or a delicate surface on them, it may be necessary to vary the blasting pressure when attending to the detail. Changing the blasting media may even be necessary to ensure that the delicate parts are not damaged. All this is determined and executed by a human worker.

Labor costs also stem from the extra processes that may need to be done pre or post-sand blasting. For example, a workpiece may need to be polished and buffed, and there may be a lot of cleaning up that may need to be done after a sandblasting job is completed.

3. Equipment and power cost

The more expensive a machine is for a sandblasting company to purchase and run, the more you will pay for using that machine. For the owner of the machine to get a return on their investment (purchasing the sandblasting machine), the owner has to charge a premium price to ensure that he/she recovers the cost.

Running the machine comes with expenses like maintenance and power. Machines will require servicing from time to time as well as replacement of components. These costs are passed on to the customer to keep the business afloat.

In general, the larger the area of your workpiece the more you pay because this directly translates to keeping a machine on for a longer period, thus consuming more electrical power. Each machine has a power consumption (power-per-hour) cost.

These costs are predetermined by the company and are factored into the process cost-per-hour charge.

This power cost is also factored into cost-per-square foot by determining approximately how long the machine takes to complete a square foot and the cost is factored into the sandblasting service.

4. Health protection cost

Dry blasting is known to produce a lot of dust, and this puts the workforce in danger. As such, most countries have strict regulations for the health and safety procedures that must be followed for sandblasting processes in general.

A special permit may need to be obtained before sandblasting can be permitted on a premises.

Appropriate personal protective equipment such as an abrasive blasting respirator must be worn by the operator. It must cover the operator’s head, neck, and shoulders to protect them from rebounding abrasives.

The operator must also wear safety shoes, gloves, and earplugs to ensure that all body extremities are adequately covered.

Safely disposing of the spent media is a cost to consider. Costs of building containment zones may also be incurred by companies.

Containment methods such as blast-cleaning machines and cabinets to control the hazard and protect nearby workers from exposure may need to be employed to promote ongoing health and safety standards.

Some regulations also make it mandatory for sandblasting operators to undergo medical examinations after a specified period.

5. Summary

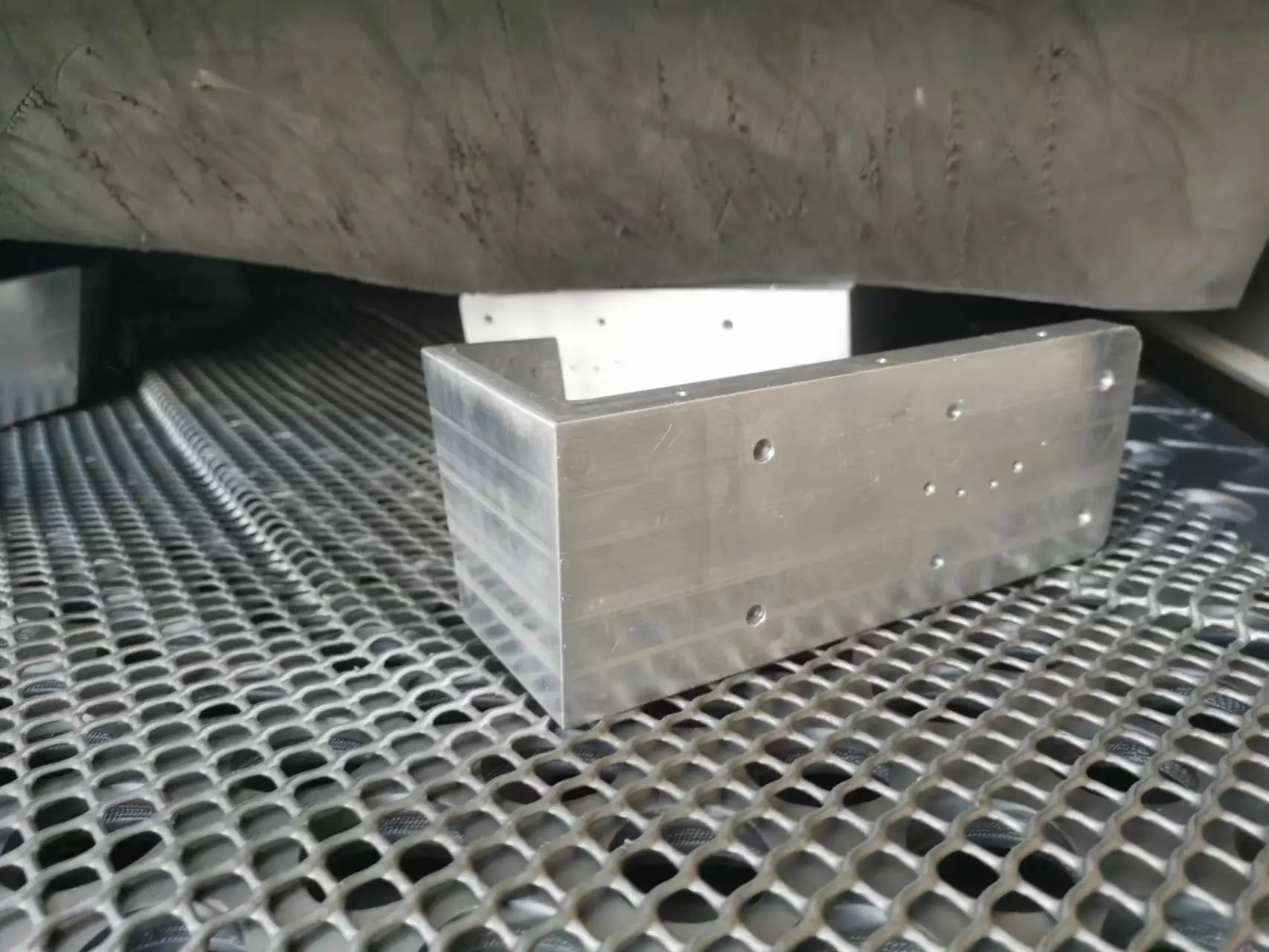

For CNC machining metal parts, such as aluminum prototypes, the sanding blasting cost is determined by blasting media, labor, equipment, and health protection. It’s different among sandblasting types and media.

Feel free to contact us for sandblasting service. ECOREPRA is the leading CNC machining and surface finish supplier in China.